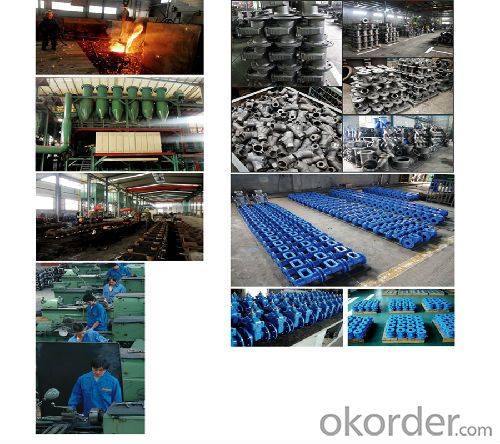

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sizes: DN100 - DN800

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80 C

Connection: RF

Constant Head Check Valve

Sizes: 4“ - 48"

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80°C

Connection: RF

| aterial list(CN standard): | |||||

| NO. | Part Name | Carbon Steel Series | Stainless Steel Series | Alloy Steel Series | Low-temperature Steel Series |

| 1 | Body | WCB | CF8 | WC6 | LCB |

| 2 | DISC | WCB | CF8 | WC6 | LCB |

| 3 | Washer | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 |

| 4 | Bonnet | WCB | CF8 | WC6 | LCB |

| 5 | Studs | 35CrMoA | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 6 | Nut | 35# | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 7 | Spring | 60Si2Mn | 0Cr18Ni9(304) | 0Cr18Ni9(304) | 0Cr18Ni9(304) |

| Technical Specification: | |||||||

| Design Standard | GB/T 12235 | ||||||

| Temperature Pressure Rating | GB/T 12224 | ||||||

| Structural Length | Factory Standard | ||||||

| Flange Dimensions | GB/T 9113,GB/T 79 | ||||||

| Inspection and Test | JB/T 9092,GB/T 13927 | ||||||

| nominal pressure | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 | PN16.0 | |

| Test Pressure(Mpa) | Body Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24.0 |

| High Pressure Seal | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 17.6 | |

| Low Pressure Seal | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable temperature | -196°C~550°C(Differeent temperature use different material) | ||||||

| Applicable Medium | water,gas,oil and corrosive media(different media use different material) | ||||||

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Carbon Steel, Stainless Steel | Temperature of Media: | Medium Temperature |

| Media: | Water, Oil, Gas etc. | Port Size: | DN250 | Place of Origin: | Hebei, China (Mainland) |

| Model Number: | OEM | Brand Name: | cmax | Application: | General |

| Name: | Check Valve | Type: | Lift Check Valve | Nominal Diameter: | DN15~900,NPS 1/4 ~36 |

| Nominal Pressure: | PN1.0-16.0MPa,ANSI CLASS 150-900,JIS10-20K | Connection Type: | Flange, butt welding, thread, socket welding, the clamp, etc | Working Temperature: | -196℃~540℃ |

| Valve Body Material: | WCB,CF8(304),CF3(304L),CF8M(316),CF3M(316L), | Applicable Medium: | Water, Oil, Gas etc | Model: | OEM |

| Certificate: | ISO9001, ISO4001 |

Application

Petroleum, chemical industry, pharmacy, fertilizer, power industry etc.

Advantage

1.Lift check valve is self-sealing valve. The disc can be acted by the flow which can protect against the media flow back.

2.The disc with spring can keep the valve work in any direction.

3.Reasonable structure, reliable sealing, excellent performance and attractive appearance make a TKFM valve.

- Q: Can the flue check valve and kitchen check valve protect against odor?

- Not really. It depends on what valve it is. If it is a variable pressure air valve, of course, if it is an ordinary other valves, generally only temporary role. Five residential home kitchen platoon smoke system is the application of this variable pressure air valve.

- Q: Can the check valve be horizontally installed?

- Lift check valve can be divided into straight through and vertical two. Straight through lift check valve can only be installed in horizontal pipe, vertical lift check valve is usually installed in vertical pipe.

- Q: What's the use of the check valve?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure.

- Q: What's the difference between check valves and non-return valves?

- Check valves are check valvesThe check valve is only a one-way start and stop valve to prevent the flow of fluid medium on all kinds of pipelines or equipment.Check valves are widely used and come in many different types,The following is a common check valve for water supply and heating:1, spring: the liquid from the bottom up, rely on the pressure spring controlled valve,After the pressure disappears, the spring force presses down the disc and seals the liquid back.Often used in the smaller diameter check valve.

- Q: Pump adapter need check valve?

- Pump adapter need check valve?

- Q: Are the common check valves stand upright or horizontally installed?

- 2. swing check valves are generally installed on horizontal or vertical or inclined pipes.

- Q: The difference between check valve and check valve

- One way valve is also called a check valve, the two is the same kind of valve, meaning the same.

- Q: What does the swing check valve "h44h-16" mean?

- Swing check valve with the built-in rocker swing structure, all opening and closing parts are arranged in the valve body of the valve, the valve does not penetrate, in addition to the seal gasket and seal ring with flange, overall no leak, to prevent leakage of the valve may be. Swing check valve rocker and disc connections using spherical connection structure, so that the valve in the 360 degrees within a certain degree of freedom, there is appropriate micro position compensation.

- Q: Fire hood fire check valve okay?

- 1, the new product role2, the role of soot exhauster smoke exhaust fumes sent to the public flue gas pipeline, with the smoke fumes from the flue gas flow into the room to ensure that the quality of the domestic air environment, home health3, fire valve temperature control device and block check plate up to prevent the flame through public exhaust pipe series.4, the specific selection to check, see products through fire products, testing, assessment, no certificate, and price

- Q: What is the difference between globe and check valves?

- 1. check valve is called one-way valve, the role is to prevent fluid flow, can not be adjusted, can not be closed.2., the cut-off valve can be used to regulate flow, can be closed, can be closed.

Send your message to us

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords