Cast iron check valve High Quality China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 4000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Medium Temperature |

| Media: | Water | Port Size: | DN40-300 | Place of Origin: | China (Mainland) |

| Model Number: | CMAX-BCV05 | Brand Name: | CMAX | ball check valve: | cast iron ball check valve |

| DIN3202 ball check valve: | DI ball check valve |

Packaging & Delivery

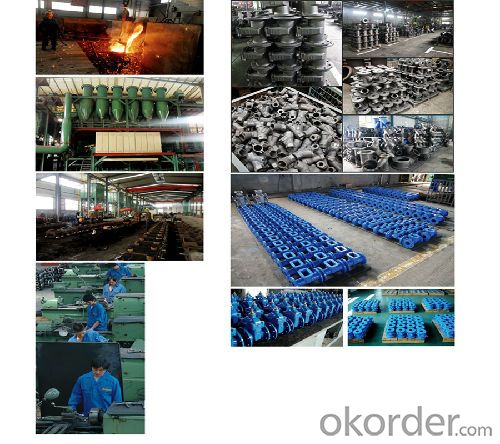

| Packaging Details: | wooden box for exporting |

| Delivery Detail: | 30--60 days |

Specifications

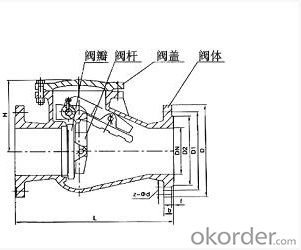

DIN 3202 F6 ductile iron ball check valve

high quanlity DIN ball check valve with lower price, body material : ductile iron and DIN 3202 F6 ductile iron ball check valve

ball check valves

1.size:PN16,DN40-DN400

2.certificate:ISO9001 CE

3.gurantee:12months

4.packing:plywoodcases

available medium:x-water T-water,steam,W-petroleum products

working temperature:X-≤50 T-≤200oC W-≤100oC.

flange dimensions:DIN2533

face to face dimensions:DIN3202F6

1.Technical Date:

Size: DN40-DN600

Nominal Pressure: PN10/PN16

Operation Temperature: -10°C~425°C

Suitable Medium: Water.

2.Feature

1) the valve is suitable for use in medium for water, oil, steam piping, as to prevent the medium counter-current, H44H type can also be used in the corrosive gas and liquid medium in pipeline;

2) the valve flange connection, connection size according to the provisions of the JB78-59 structure length according to the provisions of the JB96-75;

3) the valves on the pressure of the inlet medium effect, the valve opens, media through; When the inlet pressure drop or disappear, the disc due to gravity and the role of the outlet pressure of medium, since the valve closed, preventing medium counter-current;

4) product model: H44T - 10. Technical parameters Nominal pressure PN (MPa)1.0 working temperature (℃) < 200

Performance description: applicable to medium for water, oil, steam piping, as to prevent the medium counter-current, H44H type can also be used in the corrosive gas and liquid medium in pipeline.

- Q: Furnace blower outlet check valve what

- Must install check valve to prevent downtime fan reversal

- Q: Automatic water tower water reflux, plus a check valve not supposed

- Check the direction of the installation is correct, check valve quality is good, you can install two check valve. Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: How many kinds of check valves should be used?

- Ball check valve because the sealing part is covered with rubber ball, therefore, good sealing performance, reliable operation, anti water hammer performance; the seals can be a single ball, they can make more balls, so you can make large caliber. But its seal is wrapped in rubber hollow sphere, does not apply to high pressure pipeline, only applies to the middle and low pressure pipeline.Because the shell material of spherical check valve can be made of stainless steel, sealed hollow sphere parts can be coated PTFE plastics, can also be applied in the pipeline so general corrosive medium.The check valve in the working temperature between -101~150 DEG C, the nominal pressure is less than 4.0Mpa, nominal in the range of 200~1200mm

- Q: What is the difference between the check valve rcvx and SFCV?

- SFCV rubber check valve parts design mainly by the body, valve cover and rubber valve composed of three major parts. Its main features are: rubber valve in the valve by the steel plate, steel bar and reinforced nylon cloth as the substrate, the outer rubber covered, the valve switch life of up to 1 million times. H44X (SFCV) series rubber check valves adopt full flow area design. They have the characteristics of small head loss, easy accumulation of debris, easy maintenance and so on. H44X (SFCV) series rubber check valve is mainly suitable for horizontal installation of water supply and drainage system. It can be installed at the water outlet of the pump to prevent backflow and water hammer damaging the pump. H44X (SFCV) series rubber check valves can also be installed on the bypass pipe of the reservoir inlet and outlet to prevent backflow of water to the water supply system. Check valves are generally applicable to clean media and are not suitable for media containing solids and viscosity.Analysis of the main characteristics of RCVX rubber valve check valve: the valve body, valve cover, valve and spring, mainly used for pipeline industry departments of water supply and drainage system, oil and chemical exports, to prevent the media counter. Due to the design of the sealing ring of the product, the closing time is short, and the water hammer pressure can be reduced. The valve is made of nitrile rubber and steel plate by high temperature. It is resistant to erosion and has good sealing performance. The product structure is simple, and the maintenance, maintenance and transportation are very convenient.

- Q: What does the number 16 on the check valve mean?

- This is the pressure level of the valve, which represents 16Kg, which is used for piping pressure less than this pressure.

- Q: What is the function of the ventilator's check valve?

- When the soot exhauster stops working, the one-way valve plate is automatically closed under the action of gravity, and the fume passage is isolated from the common flueThe smoke in the flue doesn't flow back in.

- Q: How do I install the pump outlet check valve?

- Order note: 1. Pump outlet check valveProduct name and model number 2. Whether or not to take accessories for our correct selection. Use pressure. Use medium temperature.Two, if the company has been selected by the design unitPump outlet check valve type, please pump outlet check valveThe model is ordered directly from our sales department.Three, when the use of the occasion is very important or the environment is more complex, please try to provide design drawings and detailed parameters, by our valve company experts for your audit checks. If you have any questions: please call us for advice:,We will do our best to provide you with quality service.

- Q: How to install the kitchen flue check valve?

- To see what the pipeline, the installation of the location of pipe drilling (Professional) wall pipe, according to the back valve installation size, with percussion drilling, with expansion bolts fixed. The calcium carbonate pipeline is directly fixed with screws (hardness is better)

- Q: I also calculate each pump check valve and gate valve?

- The pump adapter itself does not include the gate valve and the check valve! Only when a group called pump adapter will include adapter, gate valve and check valve!If the pump adapter in the list of units for the group then all included and work content in clear note on the contents.If you do it alone, write out no items!

- Q: Are check and check valves the same kind of thing?

- Yes, that's right. Ha-ha。 My friend needs an anti - stop valve to find me. I have one for sale here.

Send your message to us

Cast iron check valve High Quality China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 4000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords