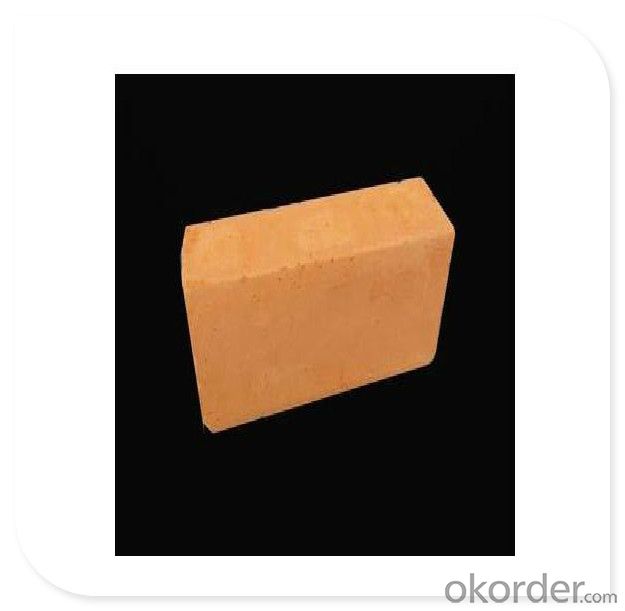

High Alumina Bricks for Lime Kiln Insulation and Fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation Fireproof High Alumina Refractory Bricks used for Lime Kilns

Production description

High alumina refractory brick contain Al2O3 more than 60%, which is made of high grade bauxite through high temperature calcinations. Its refractories is usually above 1750 °C. The main mineral components are corundum and mullite phases. It is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. According to Al2O3 content,it can be divided into three degrees:The Al2O3 content is more than 75%.The Al2O3 content range from 60% to 75%.The Al2O3 content range from 48% to 60%.

What are the advantages of our refractory bricks?

1. High-temperature endurable .

2.Good thermal shock resistance.

3.High cold crushing strength

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

How many types are there in our refractory bricks

According to the using eqiment:The high alumina is divided into different kinds according to the content alumina and usage,they are widely used in glass furnace, blast furnace,hot blaststoves electric arc furnace,cement kiln and other heat-engineering equipments.

According to its property and function :Common high alumina bricks,phosphate-bonded high alumina bricks for cement kiln,spalling resistance high alumina bricks.

products \index | code | Al2O3≥ | Fe2O3≤ | Bulk Density≥ | Apparent Porosity ≤ | Cold crushing strength ≥ | Refractoriness under load ≥(0.2Mpa) |

Unit | %

| g/cm3 | % | MPa |

°C | ||

High alumina brick | LZ-48 | 48 | 2.0 | 22 | 35 | 1420 | |

LZ-55 | 55 | 2.0 | 22 | 40 | 1450 | ||

LZ-65 | 65 | 2.0 | 23 | 45 | 1500 | ||

LZ-75 | 75 | 2.0 | 23 | 50 | 1520 | ||

LZ-80 | 80 | 1.8 | 22 | 55 | 1530 | ||

| phosphate combines high alumina bricks | P | 75 | 2.5 | 2.65 | 75 | 1350 | |

| PA | 77 | 2.5 | 2.70 | 75 | 1300 | ||

spalling resistance high alumina bricks.

| KSL-65 | 65 | 1.6 | 2.45 | 24 | 40 | 1500 |

| KBL-75 | 75 | 1.6 | 2.6 | 24 | 45 | 1520 | |

Production & Quality

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packing shipment

2.Quality Control

a.According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

F&A

Q1.Are you a manufacture or trader?

A:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3. Do you provide samples?

Yes, samples are available.

Q4. Do you accept OEM?

Yes, we can do OEM.

Q5.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q6.What are the payment terms?

Usually T/T,but L/C,Western Union etc are available for us.

Q7. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

Q8.How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q9.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q10.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q11.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- In short, the overall market of refractory enterprises is in a turbulent adjustment process, but the volume is still in place. Elimination is inevitable, as to how many can be eliminated, dare not assert.

- Q: Introduction of high alumina brick

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not identical. For example, European countries limit the content of Al2O3 to high alumina refractories by 42%. In China, the content of Al2O3 in high alumina brick is usually divided into three parts: I, etc. - Al2O3 content, >75%, II, etc. - Al2O3 content is 60 ~ 75%, and the content of Al2O3 is 48 ~ 60%.

- Q: What refractory material does cupola lining use?

- It's made of high quality refractory material: 1770 ~ 2000 centigrade.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

- Q: What's the price of high alumina refractory bricks?

- Their refractory bricks are of good quality and low ex factory prices. Special high alumina refractory brick factory price of 1900 yuan / ton, a high alumina brick factory price of 1650 yuan / ton... This price applies to standard size, size 230*114*65mm, more products, prices go to see.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The emphasis is on the physical and chemical indexes of low creep and high alumina bricks. The physical and chemical indexes of the high alumina bricks are different, too. They are DRL-1550And LZ-75 perform GB GB/T2988-2012

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

Send your message to us

High Alumina Bricks for Lime Kiln Insulation and Fireproofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords