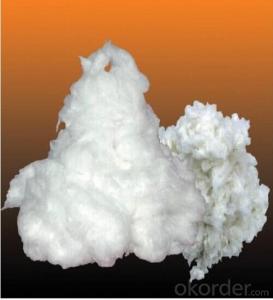

Ceramic Fiber Bulk Insulating Thermal 1260std Ceramic Fiber Loose (Bulk) for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CeramicLooseFiberis made by the melted raw materials at high temperature through resistance furnace, before being blown or spun into fiber. As a neutral and acidic material, except reaction with the strong acid-alkali,refractoryceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity. Ceramic fiber is of smaller density, more than 75% lighter than insulation brick lining or 90% -95% lighter than lightweight castable lining, with thermal conductivity co-efficient to be 1/8 of the lightweight clay brick or 1/10 of lightweight heat-resistant lining (castable), and heat capacity to be 1/10 of both lightweight insulation lining and lightweight castable lining, thus to greatly lower energy loss and deliver significant energy-saving regenerative effects. Meanwhile, the ceramic fiber features a simple construction with no need of baking oven, shortened construction cycle and easy installation.

Characteristics:

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space

Technical Data of ceramic fiber cotton

Type | Common | Standard | High Purity | High-aluminium | Zirconium | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | white | white | white | white | |

Fiber diameter (um) | Blown | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

Needled | 3-4.5 | 3-4.5 | 3-4.5 | 3-4.0 | 3-4.0 | |

Chemical composition | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 96 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Remarks: The data above is for reference. The Max. temperature depends on the using conditions.

Our service

CNBM has being specialized in producing refractory aluminum cement for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the large industrial furnace, the ceramic fiber module can be chosen to be refractory, heat insulated and insulated, and the ceramic fiber module is firmly fixed on the furnace wall by the parallel mounting method, which is more reliable

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- Ceramic fiber is a short fiber that needs to be reinforced and toughened by other objects. It is generally toughened by glass fiber and stainless steel wire. The high silicon oxygen is long fiber, no need to toughen by other objects. The short-time high silica resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber length: fiber rejection is longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;

- Q: Is aluminum silicate fiber poisonous?

- Ceramic fiber loose cotton is a kind of fluid which can melt high purity clay clinker, alumina powder, silica powder, chrome sand and so on in the industrial electric furnace.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of aluminum silicate fiber: high temperature insulation, heat preservation, fire resistance, noise reduction, insulation, light weight. Disadvantages: compressive resistance, bending force is relatively poor, easy to produce dust, waterproof performance is not very good.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- There is no full ceramic fiber material fire shutter;

Send your message to us

Ceramic Fiber Bulk Insulating Thermal 1260std Ceramic Fiber Loose (Bulk) for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches