Ace Clear Packaging Tape - Indoor Painting Adhesive Masking Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose masking tape

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

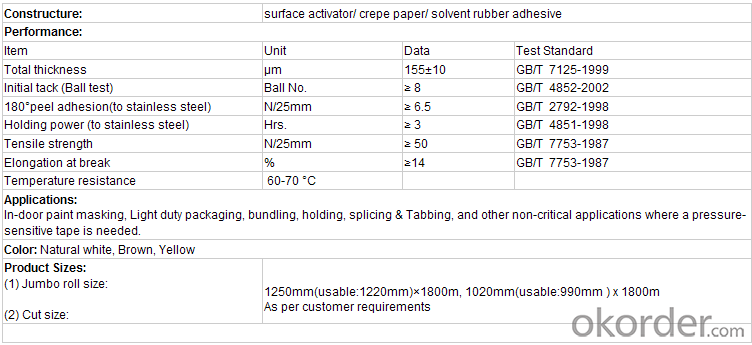

Feature

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

Specifications

Advantages:

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Is packaging tape resistant to extreme pressure or weight?

- Yes, packaging tape is designed to be resistant to extreme pressure or weight. It is specifically made to securely hold and seal packages, ensuring they stay intact even when subjected to heavy loads or pressure.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled. However, it is important to remove the tape from the packaging material before recycling.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Yes, packaging tape can be used for sealing wooden crates or pallets. It provides a secure adhesion and helps to keep the contents of the crates or pallets protected during transportation or storage.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Acrylic and hot melt packaging tapes are both commonly used for sealing boxes and packages, but they have distinct differences in terms of their adhesive properties and performance. Acrylic packaging tape is known for its clarity and transparency, making it ideal for applications where the appearance of the package is important. It is also resistant to yellowing and aging, ensuring that the tape remains clear and does not become brittle over time. Acrylic tape has a strong initial tack, meaning it adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as it can lose its adhesive strength when exposed to high heat or cold conditions. On the other hand, hot melt packaging tape is made from a synthetic rubber adhesive that is applied to the tape as a hot liquid. This type of tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It has excellent resistance to temperature changes, maintaining its adhesive properties even in extreme conditions. Hot melt tape is also known for its quick and easy release, making it convenient for high-volume packaging operations. In summary, while both acrylic and hot melt packaging tapes are effective for sealing boxes, they have different strengths and weaknesses. Acrylic tape is best for applications where clarity, aging resistance, and initial tack are priorities. Hot melt tape, on the other hand, excels in terms of adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. However, it is recommended to use a high-quality, heavy-duty packaging tape specifically designed for securing heavy items.

- Q: Can packaging tape be used for sealing packages with heavy items?

- Yes, packaging tape can be used for sealing packages with heavy items. However, it is important to ensure that the tape is strong and durable enough to withstand the weight and provide proper sealing. It is recommended to use heavy-duty packaging tape specifically designed for sealing heavy packages to ensure secure packaging.

- Q: Can packaging tape be used for sealing storage containers?

- Yes, packaging tape can be used for sealing storage containers.

- Q: Does packaging tape have any specific certifications or standards?

- Packaging tape possesses specific certifications and standards. Various organizations and standards establish guidelines for packaging materials, including packaging tape. One of the most prevalent certifications for packaging tape is the ISO certification from the International Organization for Standardization. ISO establishes quality management system standards, and packaging tape can acquire certification under ISO 9001:2015 to ensure that it meets specific quality criteria. Apart from ISO certification, packaging tape can also conform to industry-specific standards like those set by ASTM International or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards guarantee that the tape satisfies particular requirements concerning strength, adhesion, and durability. Furthermore, certain packaging tapes may possess certifications associated with their environmental impact. For instance, specific tapes may be certified as recyclable, biodegradable, or made from sustainable materials. Organizations like the FSC or the SFI grant these certifications to promote responsible forestry practices. It is crucial to note that not all packaging tapes will possess certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it indicates that the product satisfies particular quality, performance, or environmental criteria.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

Send your message to us

Ace Clear Packaging Tape - Indoor Painting Adhesive Masking Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches