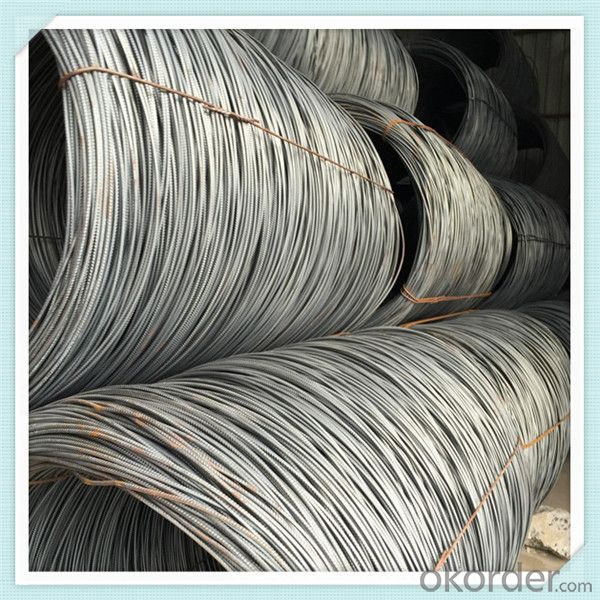

HRB400 steel wire rod hot rolled in good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14253 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Used to make steel nail, mechanical spare parts. The high carbon steel wire coil is used to make steel

wire rope for different usage, spring steel wire, steel core Al strands, galvanized steel wire, galvanized steel

strands, prestressing steel wire

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make for wire mesh.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the different sizes of steel wire rod available?

- The sizes of steel wire rod available vary depending on the specific requirements and applications. Common sizes range from 5.5mm to 16mm in diameter, with variations in length and weight. Custom sizes can also be produced to meet specific needs.

- Q: How does steel wire rod compare to other materials for wire production?

- Steel wire rod is widely regarded as one of the most suitable materials for wire production due to its exceptional strength, durability, and versatility. Compared to other materials, such as aluminum or copper, steel wire rod offers superior tensile strength and resistance to corrosion, making it ideal for various applications. Additionally, steel wire rod can be easily shaped, welded, and drawn into different wire sizes and forms, ensuring its compatibility with diverse industries like construction, automotive, and manufacturing. Its cost-effectiveness and widespread availability further contribute to its preference over other materials in wire production.

- Q: How is steel wire rod used in the production of wire for cable trays?

- Steel wire rod is a crucial component in the production of wire for cable trays. The wire rod serves as the raw material for manufacturing the wire used in cable trays. The process starts with the wire rod being drawn through a series of dies to reduce its diameter and increase its length. This drawing process helps to refine the wire rod and improve its mechanical properties such as tensile strength and ductility. Once the wire rod has been drawn, it is then further processed to form the desired shape and size of wire for cable trays. This can involve additional processes like annealing to enhance its flexibility and resistance to deformation. The wire is then coated with a protective layer, such as zinc or PVC, to provide corrosion resistance and insulation properties. The wire produced from steel wire rod is specifically designed to meet the requirements of cable tray systems. It has high tensile strength to support heavy loads and resist bending, ensuring the cable tray can securely hold and protect electrical cables. The wire's smooth surface and uniform diameter facilitate easy installation and routing of cables within the tray, preventing any potential damage to the cables. In summary, steel wire rod plays a vital role in the production of wire for cable trays. It undergoes various processes to transform it into wire with the necessary mechanical properties and coatings. This wire is then used to construct cable trays that provide a reliable and efficient solution for organizing and protecting electrical cables in various industrial and commercial applications.

- Q: How is steel wire rod used in the manufacturing of wire forms for furniture?

- Steel wire rod is a crucial component in the manufacturing of wire forms for furniture. It is used in various ways to create sturdy and durable wire structures that are essential in the construction of furniture pieces. Firstly, steel wire rod serves as the primary material for producing the wires used in furniture manufacturing. The wire rod is typically drawn through a series of dies to achieve the desired diameter and shape. These wires are then used to form the framework of various furniture items such as chairs, tables, and shelving units. Additionally, steel wire rod is often used to create springs for furniture. Springs are an integral part of furniture construction as they provide support, comfort, and flexibility to the seating or bedding surface. By using steel wire rod, manufacturers can produce high-quality springs that are resilient and long-lasting. Moreover, steel wire rod is used for reinforcing certain parts of furniture. For instance, it can be incorporated into the structure of a chair to reinforce the legs or the backrest, ensuring stability and preventing any potential damage or breakage. Furthermore, steel wire rod is utilized for creating decorative elements in furniture design. It can be bent, twisted, or shaped into intricate patterns or designs to enhance the aesthetics of the furniture piece. These decorative wire forms can be used as accents, handles, or even as the main design feature of the furniture item. Overall, steel wire rod plays a critical role in the manufacturing of wire forms for furniture. Its strength, versatility, and durability make it an ideal material for creating the framework, springs, reinforcements, and decorative elements required in furniture construction.

- Q: What are the chemical properties of steel wire rod?

- The chemical properties of steel wire rod can vary depending on the specific composition of the steel. However, in general, steel wire rod is primarily made up of iron and carbon, with trace amounts of other elements such as manganese, silicon, and sulfur. The carbon content in steel wire rod plays a crucial role in determining its properties. Low carbon steel wire rod, which contains less than 0.25% carbon, is known for its ductility and ease of forming. This type of steel is commonly used in applications where flexibility and ease of manipulation are important, such as in the manufacturing of wire products, nails, and screws. On the other hand, high carbon steel wire rod, with carbon content ranging from 0.60% to 0.85%, is characterized by its strength and hardness. This type of steel is often used in applications that require high tensile strength and resistance to wear, such as in the production of springs, cables, and piano wires. Manganese is another element commonly found in steel wire rod. It is added to enhance the strength and hardenability of the steel. Manganese also improves the steel's resistance to corrosion and promotes the formation of a fine-grained microstructure, which contributes to its overall toughness. Silicon is often present in steel wire rod as a deoxidizing agent. It helps remove any impurities from the steel during the manufacturing process and improves its ability to withstand high temperatures without deformation. Sulfur is a trace element that is typically controlled in steel wire rod production. Its presence can have a detrimental effect on the steel's ductility and toughness, therefore, it is usually kept at low levels to ensure the desired mechanical properties of the wire rod. In summary, the chemical properties of steel wire rod are determined by its composition, with the carbon content being the most significant factor. Other elements such as manganese, silicon, and sulfur are also present in varying amounts and contribute to the steel's strength, hardness, ductility, and resistance to corrosion.

- Q: What are the different types of testing conducted on steel wire rod?

- The different types of testing conducted on steel wire rods include dimensional inspection, chemical composition analysis, mechanical property testing, surface quality examination, and non-destructive testing such as ultrasonic testing, magnetic particle inspection, and eddy current testing.

- Q: What are the different steelmaking processes used for steel wire rod production?

- Steel wire rod production utilizes several steelmaking processes, each boasting unique advantages and applications. The primary methods encompass: 1. Electric Arc Furnace (EAF): This involves scrap steel melting via an electric arc. EAF is renowned for its ability to handle diverse raw materials and produce varying steel grades. It is an energy-efficient approach widely employed in wire rod production. 2. Basic Oxygen Furnace (BOF): The BOF process employs hot metal derived from a blast furnace and introduces oxygen to reduce impurities and regulate carbon content. BOF is acclaimed for its high production capacity and capacity to fabricate an extensive array of steel grades. 3. Continuous Casting: Following EAF or BOF refining, continuous casting solidifies the molten steel into billets, blooms, or slabs. This technique allows for uninterrupted production and is commonly applied in wire rod production. 4. Ladle Refining Furnace (LRF): LRF is frequently used in conjunction with EAF or BOF. It serves as a secondary refining process, facilitating control over steel's chemical composition and temperature. LRF guarantees enhanced quality and cleaner steel, rendering it suitable for wire rod production. 5. Microalloying: Microalloying entails incorporating minute quantities of elements like vanadium, niobium, or titanium during the refining process. This enhances the strength, toughness, and other mechanical properties of the wire rod. Ultimately, the selection of a steelmaking process for wire rod production rests on factors such as desired steel grade, production capacity, energy efficiency, and cost-effectiveness. Each process exhibits distinct advantages and is employed based on specific requirements and considerations.

- Q: Can steel wire rod be used for cold drawing applications?

- Indeed, steel wire rod is suitable for utilization in cold drawing applications. Cold drawing involves the act of pulling a metal rod, like steel wire rod, through a die in order to decrease its diameter and increase its length. This particular procedure aids in enhancing both the mechanical properties and surface finish of the wire rod. Due to their exceptional strength and ductility, steel wire rods are frequently employed in cold drawing applications. The elevated tensile strength of steel allows it to withstand the forces exerted during the cold drawing process without breaking or distorting. In addition, the ductility of steel allows it to be effortlessly elongated without fracturing, rendering it an ideal material for cold drawing. Throughout the cold drawing process, the steel wire rod is initially cleaned and lubricated to reduce friction and prevent surface damage. Subsequently, it is pulled through a sequence of dies, which gradually decrease the rod's diameter. As a result, a wire with a smaller diameter and increased length is obtained. The cold drawing process offers numerous advantages to the steel wire rod. It enhances the wire's mechanical properties, augmenting its tensile strength and hardness. Furthermore, it improves the wire's surface finish, resulting in a smoother and more uniform appearance. Additionally, cold drawing has the capacity to refine the wire's dimensional accuracy and tolerance. Steel wire rods are extensively utilized in various industries for cold drawing applications. They are commonly employed in the production of high-quality wires used in cables, springs, fasteners, and reinforcement materials. The cold drawing process allows manufacturers to customize the wire's diameter, length, and properties to meet their specific requirements. In summary, steel wire rod can be effectively employed in cold drawing applications. The combination of its high strength and ductility makes it an ideal material for the cold drawing process, ultimately yielding wires with improved mechanical properties and surface finish.

- Q: Can steel wire rod be used in the production of wire mesh?

- Certainly, wire mesh can be produced using steel wire rod. Steel wire rod is frequently employed as a primary ingredient for fabricating diverse wire merchandise, wire mesh included. Wire mesh is crafted by interlacing or fusing steel wires, thereby forming a mesh-like structure. Prior to its implementation in wire mesh construction, the steel wire rod commonly undergoes a process of diameter reduction and strength enhancement through a sequence of dies. Subsequently, the resulting wire mesh finds extensive usage in numerous fields, encompassing fencing, construction, agriculture, and industrial environments.

- Q: How does steel wire rod compare to other materials in terms of strength and durability?

- The market widely recognizes steel wire rod as one of the strongest and most durable materials available. When compared to alternatives such as aluminum or copper, steel wire rod stands out for its superior strength and durability. To begin with, steel wire rod possesses exceptional tensile strength, enabling it to endure substantial pulling forces without breaking or deforming. This strength proves crucial in applications where the material faces heavy loads or high-stress conditions. In contrast, aluminum or copper wire rod typically exhibits lower tensile strength, making them more susceptible to deformation or breakage under similar circumstances. Furthermore, steel wire rod showcases remarkable durability owing to its resistance to corrosion, wear, and fatigue. Steel naturally possesses the ability to withstand adverse environmental conditions, making it suitable for various harsh environments, including outdoor or marine applications. Conversely, materials like aluminum or copper are more prone to corrosion and wear, which can compromise their strength and longevity over time. Moreover, steel wire rod offers excellent structural integrity, allowing it to retain its strength and shape even when exposed to extreme temperatures or heavy mechanical stress. This characteristic makes steel wire rod highly suitable for demanding applications where safety and reliability are of paramount importance, such as the construction, automotive, or aerospace industries. In comparison, materials like aluminum or copper may experience greater deformation or loss of strength under similar conditions. In conclusion, steel wire rod surpasses other materials in terms of strength and durability. Its exceptional tensile strength, resistance to corrosion and wear, as well as its ability to withstand extreme conditions, make it the preferred choice in numerous industries. Whether utilized for structural purposes, reinforcement, or support, steel wire rod consistently delivers superior performance, ensuring reliability and longevity in various applications.

Send your message to us

HRB400 steel wire rod hot rolled in good quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14253 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords