HPMC/Hydroxypropyl Methyl Cellulose/CAS 9004-65-3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Construction Hydroxypropyl Methyl Cellulose (HPMC)

Brief introduction:

Hydroxypropyl Methyl Cellulose (HPMC) helps building materials apply more easily and perform better. They provide water retention and cohesiveness to mixtures. With special modification, it can be used to control thickening, water demand, workability, sag resistance, strength and other important properties of the final product.

It is widely used as thickener, adhesive, water preserving agent, film-foaming agent in building materials, industrial coatings, synthetic resin, ceramic industry, medicine, food, textile, agricultural, cosmetic and other industries.

Physical and chemical index:

Item | Specification |

CAS NO. | 9004-65-3 |

Appearance | white or light yellow powder |

Moisture Content | ≤5.0% |

PH | 4.0-8.0 |

Particle Size | min. 98% pass through 100 mesh |

Viscosity | 100cps-200000cps, 2% solution |

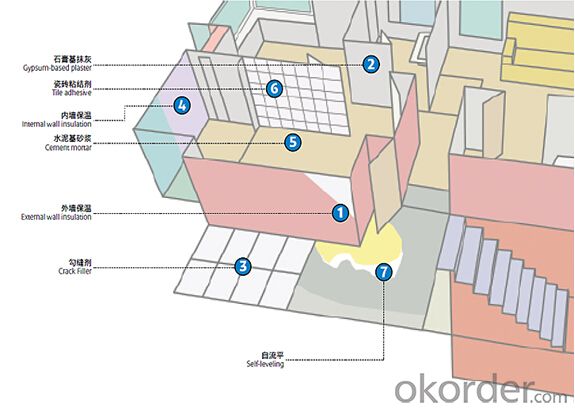

Application in Building:

External wall insulation system (EIFS)

>Bond strength: HPMC can provide the greatest degree of high adhesive bond strength of mortar.

>Performance: The mortar added HPMC has the right consistency, non-sagging. When using, the mortar is easy to work continuously, uninterrupted.

>Water retention: HPMC can wet the wall insulation easily, easy to paste, and also make other additional materials reach the best affects.

>Absorbent: HPMC can minimize the air-entraining volume, lower water absorption of mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S), 75CMAX200000(S)

Interior and exterior wall interface agent

>Easy to mix, without of agglomeration: HPMC can significantly reduce the friction in the dry powder during the process of mixing with water, which makes it easy to mix and save the blending time.

>Water retention: HPMC can significantly reduce the moisture absorption by the wall. Good water retention can ensure the cement compound with a longer time, also can ensure that workers are able to carry out many times of scraping for the putty on the wall.

>Good working performance stability: even in high temperature environment, HPMC can still maintain good water retention. it is suitable for construction in the summer or hot areas.

>Increased water demand: HPMC can significantly improve the water demand of the putty materials. On the one hand, it improves the operational time after putty put on the wall, on the other hand, it can increase the coating are of the putty, which can make the formula more economical.

>Recommended brand: 75CMAX60000(S), 75CMAX75000(S)

Tile adhesive

>Water retention: HPMC can reduce the moisture absorbed by the substrate and the tile, retain the moisture in the adhesives as much as possible, making mortar still have adhesion after coating for a long time. Significantly extend open time and makes bigger coating area for the worker each time, and improve the efficiency.

>Improve bond strength, improve anti-slip performance: HPMC ensure non sagging of the tiles during working, especially for heavy tile, marble and other stone materials.

>Work performance: The lubricity of HPMC can increase the workability of the mortar significantly, which makes the mortar easy to coating and improve efficiency.

>Improve mortar wetting property: HPMC give mortar consistency, enhance the wetting ability of mortar and substrate, increase the binding strength of wet mortar, especially for the recipe with high water cement ration;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Crack Filler

>Workability: provide the right viscosity, plasticity, and easy to work;

>Water retention: can make the slurry fully hydrated, extending the working time and avoid cracking.

>Anti-hanging: HPMC can make a strong adhesion on the surface for the slurry and not sag;

>Recommended brand: 75CMAX40000(S), 75CMAX75000(S), 75CMAX100000(S)

Self-leveling mortar

>Prevent bleeding: HPMC can play a very good role to prevent the slurry sedimentation, bleeding.

>Maintain liquidity, and improve retention: low viscosity HPMC will not affect the slurry flow effect and easy to work. While possesses certain water retention, makes the good surface effect after self-levelling and avoid cracks.

>Recommended brand: 75CMAX400~600

Gypsum-based plaster

>Water retention: HPMC can retain moisture in the mortar, thus make gypsum completely solid. The higher the viscosity is, the stronger the water-retention capacity, vice versa..

>Sag resistance: allow the worker make the thick coating without causing ripple building.

>Mortar yield: For fixed weight of dry mortar, the exist of HPMC can provide more wet mortar.

>Recommended brand: 75CMAX75000(S), 75CMAX100000(S)

FAQ

Q1.Could we have the sample to test the quality?

Kindly send us your address, we are honored to offer you samples.

Q2. How does your company do regarding quality control?

CNBM a Chinese state-owned enterprise ranked 270th among the global fortune 500 in 2015,

have accreditation in line with standard:ISO 9001:2000,SGS,CIQ certificate.

Q3:What's your Delivery Time?

In generally, the delivery time is 25 days-30 days.We will make the delivery as soon as possible with the guaranted quality.

Q4:What is the convenient way to pay?

L/C , T/T ,Paypal, Western Union and Escrow are accepted,and if you have a better idea , please feel free to share with us .

Q5:Which mode of transport would be better?

In general,we advice to make delivery by sea which is cheap and safe.Also we respect your views of other transportation as well.

- Q: High school knowledge __ teacher do not know right!

- Nothing to do, but with the percentage of activated molecules, is proportional to

- Q: What is the similarity between enzymes and general chemical catalysts?

- (1) The enzyme is the same in many respects as a biocatalyst and a general catalyst, such as a small amount and a high catalytic efficiency. As with the general catalyst, the enzyme can only change the rate of chemical reaction and does not change the equilibrium of the chemical reaction It is possible to catalyze the activation of a large number of substrates in a short time and to reflect the high efficiency of enzyme catalysis.The enzyme can reduce the activation energy of the reaction (activation) (△ G) during the reaction, but the reaction rate is accelerated and the reaction time is reduced, but the equilibrium constant is not changed. (2) However, the enzyme is a biological macromolecule (1) Enzyme-catalyzed high efficiency: The catalytic effect of the catalyst can increase the reaction rate by 10 ^ 6 ~ 10 ^ 12 times, which is at least several times higher than that of the conventional catalyst. (2) The enzyme catalyst Highly specificity: including specificity of response, substrate specificity, chirality specificity, geometric specificity, etc., that an enzyme can only act on a certain class or a specific substance. Bond, ester bond, peptide bond and so on can be catalyzed by acid-base hydrolysis, but the hydrolysis of these chemical bonds are different, respectively, the corresponding glycosidase, esterase and peptidase, that is, they were specific (3) enzymatic reaction conditions are mild: enzymatic reaction is generally carried out in aqueous solution of pH = 5 ~ 8, the reaction temperature range is 20 ~ 40 ℃

- Q: The best use of chemical catalysts

- Do not know what you want to use the best thing is what the catalyst is generally used in the process, there will be an initial induction period, the catalytic activity is relatively low, and then reached a stable catalytic state, this paragraph is generally called the catalyst life, the final Due to poisoning, active ingredient aggregation and so on factors, the catalyst activity will be reduced, then need to replace the new catalyst

- Q: Chemistry is often said that the catalyst can change the material reaction rate, rate and speed What is the difference

- Rate refers to: the amount of time in the unit reaction, and speed, and the speed simply refers to the speed

- Q: Chemical questions: "CO2 and H2 in the catalyst conditions have a reaction, the reaction of the chemical equation is"

- CO2 + H2 = CO + H2O (conditions: catalyst, generally requires heating, and reversible)

- Q: Cl + O3 ---> ClO + O2O + ClO ---> Cl + O2= O + O3 ----> 2O2What is the catalyst? The intermediate?How do you know which is which? If the rate law is rate=k [O3] [Cl]determine:a) the overall order.b) unit for k.c) the rate determining step, justify your answer.

- Cl is the catalyst. ClO the intermediate. The catalyst is the component which does not change in overall reaction. He forms some intermediate component(s) with the reactants. In the later reaction steps the intermediate(s) react forming the catalyst in its original state. (a) The overall order is the sum of the orders with respect to the components: n = 1 +1 = 2 (b) the unit of the rate of reaction is r [=] mol/ (Ls) (more general mol per unit time and volume) compare dimensions mol / (Ls) [=] k · mo/L · mol/L =k [=] L/(s mol) (more general unit volume per unit time and mole) (c) First reaction For elementary reaction steps the order of the reaction rate with respect to a reactant is equal to stoichiometric coefficient. Hence the rate of first reaction is: r? = k?·[Cl]·[O?] Overall rate is given by the rate determining step, while other reaction steps are in equilibrium: r = r? = k?·[Cl]·[O?] If second reaction is the rate determine step r? = k?·[O]·[ClO] while reaction 1 is at equilibrium K? = ( [ClO]·[O?] ) / ( [Cl]·[O?] ) =[ClO] = K?·( [Cl]·[O?] ) / [O?] the overall rate would be: r = r? = k?·[O]·[ClO] = K?·k?·[O]·[Cl]·[O?] / [O?] = k·[O]·[Cl]·[O?] / [O?] That doesn't match the observed rate law

- Q: A catalyst elevates the rate of a reaction by?

- Catalysts work by providing an (alternative) mechanism involving a different transition state and lower activation energy. Consequently, more molecular collisions have the energy needed to reach the transition state. Hence, catalysts can enable reactions that would otherwise be blocked or slowed by a kinetic barrier. The catalyst may increase reaction rate or selectivity, or enable the reaction at lower temperatures. This effect can be illustrated with a Boltzmann distribution and energy profile diagram. Take a look!

- Q: What is the quality of the catalyst in the chemical reaction, for example, 34.3 g before the hydrogen peroxide reaction, 32.7 g after the reaction, and how much is the catalyst mass?

- You can not calculate this question, the quality of the catalyst before and after the same reaction, how much reaction before the reaction on how much

- Q: Thorough explanation pls.

- Catalyst are the substances which increase the rate of reaction. They do not get consumed in the reaction but they participate in intermediate reactions. The catalyst action can be explained as- Providing alternate energy path- Let us suppose that an endothermic reaction need 15 joules of threshold energy to occur. The catalyst will provide them path which needs less energy. Providing Surface- Many reaction may occur slowly because less contact between the molecules/atoms/ions or due to unavailability of proper structure, in this case the catalyst provide surface for carrying the reactions. There are several other actions which mayn't be necessary for you to understand the basic function of catalyst.

- Q: Several experiments were carried out using catalysts

- Hydrogen peroxide in the manganese dioxide as a catalyst for decomposition reaction: 2H2O2 == MnO2 == 2H2O + O2 ↑ (laboratory oxygen principle)

Send your message to us

HPMC/Hydroxypropyl Methyl Cellulose/CAS 9004-65-3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords