Hot Rolled Steel Pipe Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

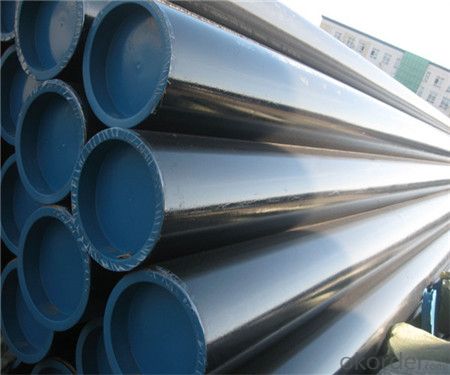

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Full series of products provides an easier access for one stop purchase

▲ Line pipe

▲ Tubing and casing

▲ L & M & H boiler tube

▲ Gas cylinder tube & pipe

▲ Mechanical & Structural pipe

▲ Ship-building tube & pipe

▲ Automobile tube & pipe

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

Why should you chose us?

● Full series of products provides an easier access for one stop purchase

▲ Electric Resistance Welded (ERW) Steel Pipe

▲ Longitudinal Submerged Arc Welded (LSAW) Steel Pipe

▲ Spiral Submerged Arc Welded (SSAW) Steel Pipe

▲ Hollow Section (Square and Rectangle Pipe)

▲ Hot Dipped Galvanized Steel Pipe

6、Seamless Pipe ASTM A106/53 Images:

- Q: What does seamless steel tube mean? What are the main uses? What are the classifications?

- Seamless steel pipe having a hollow cross section, used as a conduit for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials. Compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, the bicycle frame and steel construction with scaffold with steel pipe manufacturing ring parts can be improved the utilization rate of materials, simplify the manufacturing process, material saving and working hours, has been widely used to manufacture steel tube.

- Q: What are the environmental benefits of using steel pipes?

- There are several environmental benefits of using steel pipes: 1. Durability: Steel pipes have a long lifespan, which reduces the need for frequent replacements. This helps to conserve resources and reduces the amount of waste generated. 2. Recyclability: Steel is one of the most recycled materials in the world. When steel pipes reach the end of their life, they can be easily recycled and used to manufacture new steel products. This reduces the demand for raw materials and saves energy that would otherwise be required for the production of new materials. 3. Reduced carbon emissions: Steel pipes have a low carbon footprint compared to other materials like concrete or plastic. The manufacturing process for steel pipes produces fewer greenhouse gas emissions, contributing to a lower carbon footprint overall. 4. Resistance to corrosion: Steel pipes have high resistance to corrosion, which means they require less maintenance and repair compared to other materials. This reduces the use of chemical coatings and treatments that can have negative environmental impacts. 5. Water conservation: Steel pipes are commonly used for water supply and distribution systems. They have smooth interiors that minimize friction, reducing the amount of energy required to pump water through the pipes. This helps to conserve energy and decrease the carbon emissions associated with water transportation. 6. Fire resistance: Steel pipes are inherently fire-resistant, which makes them a safer choice for many applications. In the event of a fire, steel pipes can help to contain the spread of flames and minimize damage to the environment. Overall, the use of steel pipes offers numerous environmental benefits such as durability, recyclability, reduced carbon emissions, water conservation, and fire resistance. These factors make steel pipes a sustainable choice for various infrastructure projects.

- Q: How are steel pipes inspected for compliance with industry standards?

- Steel pipes are inspected for compliance with industry standards through various methods, including visual examination, dimensional measurements, non-destructive testing, and mechanical testing. Trained inspectors carefully inspect the pipes to ensure they meet the required specifications, such as wall thickness, diameter, and surface quality. Non-destructive testing techniques like ultrasonic testing or magnetic particle inspection are used to detect any internal or surface defects. Mechanical tests, such as tensile or bend tests, are performed to evaluate the pipe's strength and ability to withstand pressure. These inspections help ensure that steel pipes meet the necessary industry standards and are fit for their intended use.

- Q: How do you transport steel pipes safely?

- In order to transport steel pipes safely, it is essential to engage in proper planning, utilize appropriate equipment, and adhere to safety measures. To ensure the safe transportation of steel pipes, the following guidelines should be followed: 1. Select suitable transportation equipment: Opt for either a flatbed trailer or a truck with a flatbed when transporting steel pipes. Make certain that the trailer or truck is equipped with a robust and secure tie-down system to prevent any movement or shifting of the pipes during transit. 2. Secure the pipes: Use either nylon or steel straps to fasten the steel pipes to the trailer or truck bed. Ensure that the straps are adequately tightened so as to evenly distribute the weight of the pipes and prevent any potential movement or shifting. 3. Safeguard the pipes: Implement the use of pipe chocks or protective materials such as foam or rubber to prevent the steel pipes from rolling or rubbing against each other during transportation. This will aid in minimizing any possible damage and maintaining the integrity of the pipes. 4. Adhere to weight restrictions: Verify that the weight of the steel pipes being transported does not exceed the load capacity of the transportation equipment. Overloading can lead to instability and compromise safety. 5. Comply with road safety regulations: Abide by all local traffic laws and regulations, including adhering to speed limits and securing any necessary permits or licenses for oversized loads if required. Additionally, utilize hazard warning signs or flags when transporting lengthy or oversized steel pipes to alert other road users. 6. Perform regular inspections: Prior to embarking on the journey, inspect the straps, tie-downs, and other securing mechanisms to ensure they are in satisfactory condition. Regularly monitor the load during transit to guarantee its continuous security. 7. Plan the route: Select a route that is suitable for the size and weight of the steel pipes being transported. Avoid roads with low bridges, narrow lanes, or weight restrictions that may pose a hazard to the safe transportation of the pipes. 8. Consider weather conditions: Take into account weather conditions, such as strong winds or heavy rain, which can impact the stability of the load. Make necessary adjustments to the transport plan or postpone the journey if deemed necessary. 9. Train and educate drivers: Ensure that the drivers responsible for transporting steel pipes are adequately trained and knowledgeable about the proper procedures for securely and safely transporting the load. Regularly provide them with updates on safety protocols and any changes in regulations. By adhering to these guidelines, the transportation of steel pipes can be executed safely, thereby reducing the risk of accidents, damage to the pipes, and ensuring the safety of all individuals involved in the transportation process.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: How are steel pipes protected against UV radiation?

- Steel pipes are typically protected against UV radiation through the application of specialized coatings or paints that contain UV inhibitors. These coatings form a barrier between the steel surface and the sun's UV rays, preventing degradation, discoloration, and potential structural damage caused by prolonged exposure to UV radiation.

- Q: What are the different types of coatings applied to steel pipes?

- There are several types of coatings applied to steel pipes, including epoxy coatings, fusion-bonded epoxy (FBE) coatings, polyethylene (PE) coatings, polyurethane (PU) coatings, and zinc coatings.

- Q: Seamless steel tube with the tube with what is the difference?

- Seamless steel tube is integrally formed with welded steel pipe steel plate butt welding and welding seam.

- Q: How do steel pipes handle high-velocity flow?

- Steel pipes are designed to handle high-velocity flow efficiently due to their inherent strength and durability. The smooth interior surface of steel pipes minimizes friction, allowing for smooth flow and reducing energy loss. Additionally, the sturdy construction of steel pipes enables them to withstand the pressures and forces exerted by high-velocity flow without deformation or failure.

- Q: How are steel pipes used in the shipbuilding industry?

- Steel pipes are commonly used in the shipbuilding industry for various applications such as the construction of the ship's hull, piping systems for fuel, water, and other fluids, as well as for the ventilation and drainage systems on board. These pipes provide strength, durability, and corrosion resistance, making them ideal for withstanding the harsh marine environment.

Send your message to us

Hot Rolled Steel Pipe Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords