Hot new products for 2015 best price pvc flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

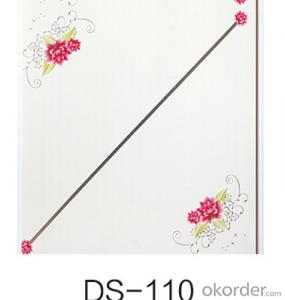

Specification

Specifications

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

Why Choose Us

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Instrctions:

1.Remove the floor trim fromt he perimeter of the floor with your hammer and prybar. Don't break it. Set it aside.

2. Lay the first row of this vinyl tiles alongside your starting wall, locking them together at the ends. Put shims between the tiles and the wall, to create a space that will allow for floor expansion. Lay all the full tiles that will fit.

3. Measure the space at the end of the first row of tiles. Use your utility knife to cut a tile to size, running the knife alongside a straight-edge to score it, and then snapping the tile. Lay it with the cut side facing the wall.

4. Lay the next courses of tiles alongside the first building out in courses. Start each course at the opposite end of the room as the previous course, so the ends of the tiles don't line up between courses. Lock the tiles together by their long edges,pushing them in at a downward angle, locking then, then dropping then into space. Cut the ends as necessary.

5. Cover the whole floor. Cut the final course of tiles length-wise, so they fit against the wall with a small gap there(about 1/4 inch).

6. Nail the floor trim back in place, using your hammer and finish nails, to seal off the spaces by the walls. Nail toe trim into the walls and not through the flooring.

Technical Data

Safety Criteria | Standard | Value |

Flammability | EN 13501-1 | Bf1 |

Slip resistance | EN13893 | DS |

Formldehyde Emission | EN717-1 | None |

Color Fastness | ISO 105-BO2 | ≥ 6 |

Castor Wheel Test | EN425 | Pass |

- Q: There is a little water with plastic sheeting can pave the floor?

- Note gapThe first floor and the wall to leave room, in the room, the door and the stairs and other fixed facilities connected to the same, leaving gaps, general length between 0.8 cm -1.0 cm.

- Q: EVA plastic floor and PVC plastic floor which is good

- You don't know what is the use of hanging material, I think it is a good floor, PVC

- Q: Composite floor plastic sheeting down the impact of heat

- The floor of the thermal resistance value is 5 times the floor tile, the same inlet temperature, the room floor is better than low floor tile room above 3 degrees, your home is normal, remove the film under the floor as not useful, the fundamental reason is that your home water temperature is too low, usually the floor room, into the water temperature above 50 degrees, up to 55 is will be very hot. I estimate your home water temperature will not reach 45 degrees will appear this situation. And warm design relationship

- Q: What is the role of the floor mat plastic sheeting

- Moistureproof layer. A layer of linoleum or plastic film, the ground will be able to cut off the water vapor condensed, and let it pass around the foot of a wall left side seam, emitted into the air. Moisture proof material integrity, damage or joints should be repeated cover. Now some of the lower ground floor of the house to do a half basement treatment, can also play a better role in moisture.

- Q: Badminton plastic floor? Want to be a sports venue, which plastic sports floor brand is better

- Indoor badminton venues are now using plastic floor, cost-effective, and very environmentally friendly

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money the plastic floor, Shanghai plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, size of plastic flooring, plastic flooring specifications, plastic floor how much money Nanjing Hefei Yiping, plastic floor, plastic floor

- Q: How to spread the plastic floor?

- With multi-layer solid wood board paved on the floor tile on the line, it is worth noting that the plastic plate is flat buckle

- Q: What are the hazards of plastic floor?

- The utility model relates to a plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, and is added with appropriate auxiliary agent

- Q: What is the plastic floor?

- Plastic floor, plastic floor. Plastic floor according to the operation state can be divided into blocks (or tiles) and coil (or floor) two. According to its material can be divided into hard, semi hard and soft (elastic) three. According to its basic raw materials can be divided into polyvinyl chloride (PVC) plastic, polyethylene (.PE) plastic and polypropylene (PP) plastics, etc..

- Q: The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- Every one in the family of 2-3 2.5mm root canal - wire is up to 3 4mm - 20, PVC tube enough protection layer plus 15mm, also tick the 40mm deep. This is the norm

Send your message to us

Hot new products for 2015 best price pvc flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords