Hot-dipped Galvanized Hardware Cloth with Multipurpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Hot-dipped Galvanized Hardware Cloth Description:

Hot-dipped Galvanized Hardware Cloth or welded mesh, is made from choice plain wire and stainless wire, which shows good corrosion-resistance and oxidation-resistance, widely used for poultry houses, egg baskets, runway enclosures, draining racks, porch guards, rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

Hot-dipped Galvanized Hardware Cloth is made of high quality low carbon steel wire line of welding and become, then cold (plating), hot dip plating, PVC plastic coated surface passivation, plasticizing treatment, etc. To achieve the smooth surface, uniform mesh, solder joint is firm, local good machining performance, stability, anti-corrosion, good corrosion.

2. Main Features of Hot-dipped Galvanized Hardware Cloth:

• Antirust

• Durable

• Nice Visual

• Good anti-corrosion

• Practical use

• User-friendly

• Versatile

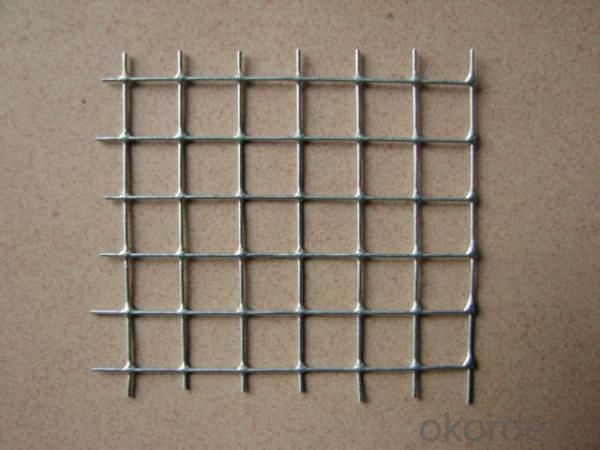

3. Hot-dipped Galvanized Hardware Cloth Images

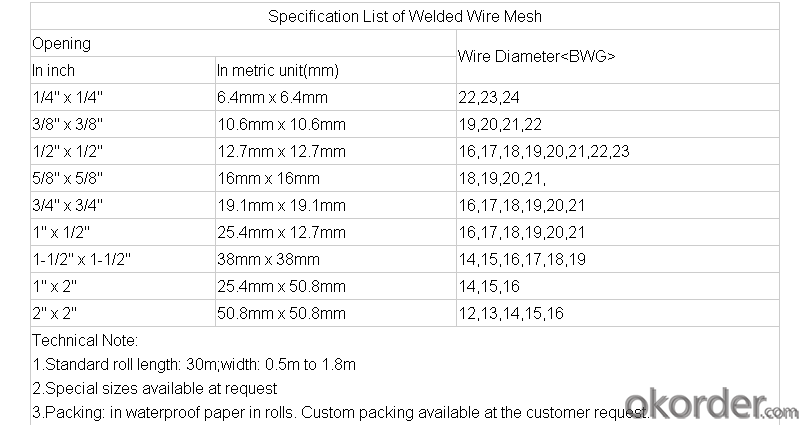

4. Hot-dipped Galvanized Hardware Cloth Specification

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①How about your Hot-dipped Galvanized Hardware Cloth?

We have 20 years' experience for export/produce Hot-dipped Galvanized Hardware Cloth. About 100 person works in this line, 10 production lines can produce about 200 sets every day. We have our own quality inspection departments to strictly according to customer requirements to complete production. Which have exported to lots of countries before such as: Australia, Italy, Mexico, and Gaborone, Kenya..... And so on. We have a professional management team and many skilled workers Owns 20 production lines, we have a strong production capacity We can provide high-quality products.

②What is the advantage of our Hot-dipped Galvanized Hardware Cloth:

(1)Our quality management system conforms to the ISO 9001, ISO14001 and SGS guidelines and we check each step in the production process.

(2) We purchase raw materials from well known manufacturers in China, and inspect materials before warehousing.

(3) We have our own production line and can offer you the competitive price.

(4) To provide quality low-cost custom services.

③How long can we receive the product after purchase?

In the purchase of Hot-dipped Galvanized Hardware Cloth within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: This material of the barbed wire in the water I do not know how long?

- Protection and shielding effect of the outermost layer of glue is insulated, the role of fire inside some iron / copper layer, is the protection and shielding effect of the innermost copper wire, is the current effect, used for conductive transmission

- Q: Wall tiles how to hang iron wire mesh

- Coating is thin, usually within 5-30 microns, so the anti-corrosion time will be relatively short. Cold galvanized wire mesh features: mesh formation, mesh uniform, solid solder joints, local processing performance, bright colors, beautiful. Cold galvanized wire mesh Uses: Widely used in industrial and agricultural construction fence.

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- Acceleration of heat dissipation, because the thermal conductivity of iron is relatively strong, so the ground heat evenly.

- Q: In the chemical experiment, how does the wire mesh use? What are the effects?

- So that the catalytic reaction of iron as a catalyst is more pronounced for the blocking effect. In the solid-liquid reaction in a kind of controllable gas

- Q: What is the barbed wire in the cable line?

- The wire mesh in the cable line is the shield. The role of shielding network is to shield the external environment of the spurious radio signal.

- Q: What is the barbed wire fence? What is the general specification?

- Anti-destructive performance, good steel, handsome in appearance, wide field of vision, easy to install, feel bright and relaxed.

- Q: Why is the effect of electromagnetic radiation shielding with wire mesh?

- My home next to 20 meters is 500 kV high voltage power grid, so I first measured under the line, and then home to the test, should be the frequency of magnetic field

- Q: Is the warm tube laid on top of the steel wire or below?

- on the maintenance of the warm tube I told you to see what you use the pipe to decide, if the use of high temperature polyethylene PE-RT material, then you can use a dedicated interface to hot-melt connection to repair, if used Is the coach polyethylene PE-X pipe, then it is difficult to deal with,

- Q: What is the use of wire

- Iron is a long time will rust. Iron easily rust, in addition to its chemical nature of lively, but also with the outside world conditions also have a great relationship.Water is easy to rust the iron one of the material, iron into the water

- Q: Why do you want to shop a barbed wire?

- Finally, after the core wall of the cement touched, with the level of correction that looks very flat, so whether it is from the aesthetic level or practical

Send your message to us

Hot-dipped Galvanized Hardware Cloth with Multipurpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords