Hot-dip Galvanized Rolled Pickled and Oiled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip galvanized/aluzing steel description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy ,strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications

Quick Details

Standard:AISI, ASTM, BS, GB, JIS 3302

Thickness: 0.13-1.2mm

Type:Steel Coil

Technique:Hot Rolled

Surface treatment:galvanized

Application:Container Plate

Special Use:High-strength Steel Plate

Width:750-1250mm

Length:as your requirements

Certification:ISO9001:2008

Grade:DX51D,SGCC,ect

Zinc Coating:galvanized(GI)

Zinc thickness:40-275g/m2

Coil ID:508mm/610mm

Coil weight:3-8 MT

Surface structure:regular/big/zero spangle

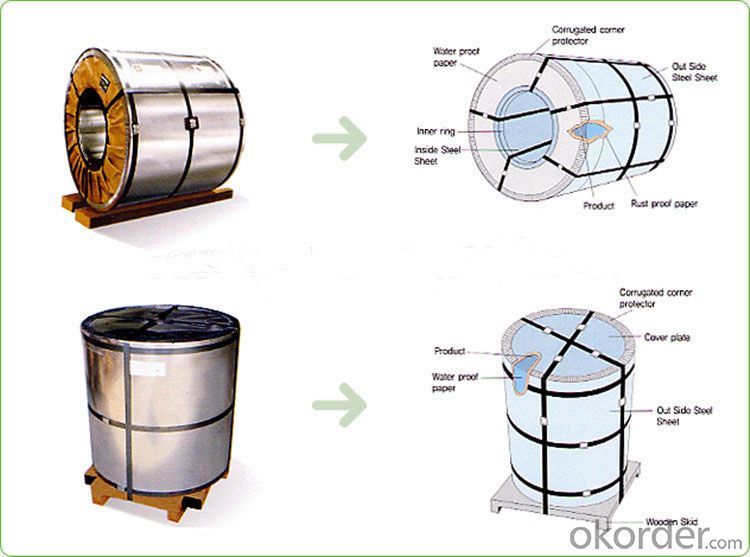

Packaging & Delivery:

Packaging: Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal

Details:waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection

Delivery Detail:within 15 working Days after 30% deposit or L/C at sight

Figure pictures:

Main Specification:

Galvanized steel coil | |

Product | Galvanized steel coil |

Zinc coating | 30-120g/m2( as required) |

Thickness | 0.13-1.2mm |

Width | 750-1250mm(750-762mm,900-925mm, 1000, 1200-1250mm the most common) |

Coil id | 508mm |

| Coil weight

| 3-5MT or more (as required) |

Surface | regular/mini/big spangle, skin pass, chromated, unoiled, dry etc. |

Tolerance | Thickness tolerance: +/- 0.02mm Width tolerance: +/-5mm; |

Payment condition | Prepay 30%, pay the rest before shipment, via TT |

Application | As to excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect. |

Packing:

For coils: Anti-rust paper +metal cover +corner protected +wood skid Laded into 20 feet container with max weight 25 tons;

For sheets: Thin plastic film +rust-proof paper +metal cover +metal angles + straps + pallet. Loaded in 20 feet container with max weight 25 tons

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the common sizes of steel coils used in the industry?

- The common sizes of steel coils used in the industry vary, but some of the standard sizes include 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, and 2.5mm. However, it's important to note that different industries may have specific requirements and may use custom sizes depending on their applications.

- Q: What are the dimensions of steel coils used in the automotive industry?

- The dimensions of steel coils used in the automotive industry can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in the automotive industry range from 0.5mm to 3mm in thickness and from 500mm to 2000mm in width. The length of the coils can vary depending on the production process and customer specifications. Additionally, the weight of the coils can range from a few hundred kilograms to several tons. It is important to note that these dimensions are general guidelines and can vary depending on the specific needs of the automotive manufacturer.

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- pl. be specific about the type of steel: (Steel is a metal alloy whose major component is iron, with carbon content between 0.02% and 1.7% by weight. Carbon is the most cost effective alloying material for iron, but many other alloying elements are also used.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and their distribution in the steel controls qualities such as the hardness, elasticity, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle. The maximum solubility of carbon in iron is 1.7% by weight, occurring at 1130° Celsius; higher concentrations of carbon or lower temperatures will produce cementite which will reduce the material's strength. Alloys with higher carbon content than this are known as cast iron because of their lower melting point.[1] Steel is also to be distinguished from wrought iron with little or no carbon, usually less than 0.035%. It is common today to talk about 'the iron and steel industry' as if it were a single thing; it is today, but historically they were separate products. Currently there are several classes of steels in which carbon is replaced with other alloying materials, and carbon, if present, is undesired. A more recent definition is that steels are iron-based alloys that can be plastically formed (pounded, rolled, etc.). Iron alloy phases : Austenite (γ-iron; hard) Bainite Martensite Cementite (iron carbide; Fe3C) Ferrite (α-iron; soft) Pearlite (88% ferrite, 12% cementite) Types of Steel : Plain-carbon steel (up to 2.1% carbon) Stainless steel (alloy with chromium) HSLA steel (high strength low alloy) Tool steel (very hard; heat-treated) Other Iron-based materials : Cast iron (2.1% carbon) Wrought iron (almost no carbon) Ductile iron)

- Q: Can steel coils be used in corrosive environments?

- Yes, steel coils can be used in corrosive environments, but their performance will depend on the type of steel and the severity of the corrosive environment. Stainless steel coils, for example, are highly resistant to corrosion and can be used in a wide range of corrosive environments, including those with high levels of moisture, chemicals, or salt. However, other types of steel coils may require additional protective measures, such as coatings or galvanization, to enhance their resistance to corrosion. It is important to consider the specific corrosive factors present in the environment and choose the appropriate type of steel and protective measures to ensure the longevity and durability of the steel coils.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- as has been said before it is a mystery steel that could mean anything honestly I am guessing closer to 1045 than the already mentioned 1095.... or just stainless steel of some variety tldr we all are telling the truth do not buy it

- Q: How do steel coils differ in terms of size and weight?

- Steel coils can differ in terms of size and weight based on the specific requirements and applications. The size of steel coils can vary depending on the industry and intended use, ranging from small coils weighing a few hundred kilograms to larger coils weighing several metric tons. The weight of steel coils is primarily determined by the thickness, width, and length of the coil, with thicker and wider coils generally being heavier. Therefore, the variation in size and weight of steel coils is based on the specific needs of different industries and applications.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide the raw material for forming the enclosures' outer shells and structural components. The steel coils are processed and shaped through various techniques such as cutting, bending, and welding, to create the desired size and shape of the enclosure. The steel's strength and durability make it an ideal material choice for ensuring the enclosures can protect electrical equipment from environmental factors and provide safety for users.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through a series of visual and mechanical tests. Firstly, the external appearance of the coil is examined to ensure it is free from any visible defects such as dents, scratches, or rust. This is important as it ensures the coil's overall integrity and prevents potential issues during further processing. Next, the thickness of the coil is measured at various points using non-destructive testing techniques like ultrasonic or magnetic particle inspection. This helps identify any variations in thickness, which could affect the coil's overall quality and performance. Additionally, the width of the coil is measured using precision instruments to check for any deviations from the required specifications. This ensures that the coil is within the desired width range, which is crucial for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. This is typically done using weighing scales or load cells, ensuring that the weight is consistent and meets the required standards. In terms of internal inspection, steel coils are sometimes subjected to eddy current testing, a non-destructive method that detects surface and near-surface defects. This technique uses electromagnetic induction to identify any irregularities in the metal, enabling the identification of defects such as cracks, voids, or inclusions. Overall, a combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures that steel coils are thoroughly inspected for uniformity. These rigorous inspection processes help guarantee the quality and reliability of the coils, allowing them to meet the industry standards and customer requirements.

- Q: How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components as they are rolled into flat sheets and then further processed to create various parts such as body panels, frames, and chassis. These coils provide the necessary strength and durability required for automotive applications, ensuring the safety and performance of vehicles.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyurethane, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP).

Send your message to us

Hot-dip Galvanized Rolled Pickled and Oiled Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords