HOT Color Stone Coated Steel Roof Machine, Stone Coated Metal Eoof Tile Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

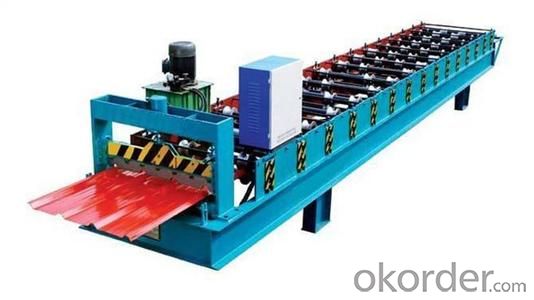

This type of Glazed Tile Roll Forming Machine has advantage incoulding beautiful and classical appearance grace tasty, it is widely used in factory which looks like a park, tour spot, elegant buildings for landscaping purpose, hotel, exhibition, vocation village, family construction and outdoor decorate.

This machine is composed of feed leading table, main forming machine, mould former device, cutting device, hydraulic station, computer control system and so on.

Optional devices: normal holder, hydraulic holder, auto-stacker and discharge table.

Product Description of Glazed tile roll forming machine

1. Suitable to process: Colored Steel plate, galvanized board

2. Width of the plate: 1000mm

Glazed tile roll forming machine

Parameter:

1. Appearance size: 7600mm*1350mm*1510mm

2. Wheel material: 45#steel

3. Blade material: CR12

4. Chromium coating 0.05mm

5. Control system: PLC control

6. Power of electrical motor: 3+3KW

7. Power 380V 50 Hz, 3 Phase

8. Speed of product: 2-3m/min

9. Thickness range: 0.3-0.6mm

10. Purpose: Roof board

11. Board's width: 1000mm

Machine components:

1. Forming machine 1set

2. Hydraulic pressure system 1set

3. Auto-cutting knife 1 set

4. Computer controlled box 1set

5. Moulding press machine 1set

6. Man-made holder 1set

- Q: What steps are required during the installation of the cement tile machine?

- Feeder installation: adjust the plane of the plate on the plate by the position shown in the figure. The plane of the shaking table is in a plane, and the board is aligned with the main axis to adjust the distance between the boarding machine and the vibration platform. Pallets in the transport when the smooth fall in the middle of the shaking table, the debug board will be connected to the host board and fixed.

- Q: Analysis on the Problems of Cement Shade Machine

- Use the primer, especially the local repair; to ensure that the thickness of the same layer; to ensure the use of consistent tools, the use of the same batch of products to ensure that the construction conditions,

- Q: The processing method of the tile machine

- The billet is soft. Filter cloth part of the paste was dead, the next model of the local filter hole blocked, clean up. System without pressure, pump reversal: wiring error, adjust the steering. Insufficient power: motor failure or low voltage, power supply or repair motor. Oil pump temperature is too high: oil viscosity is too low, the pump is damaged, the cooling is insufficient or interrupted.

- Q: What are the advantages of cement tile machine?

- advanced and efficient. A new generation of equipment to add a remote control, diagnostic system, thousands of miles away on the operation of the data analysis, so that customers on the equipment maintenance easier.

Send your message to us

HOT Color Stone Coated Steel Roof Machine, Stone Coated Metal Eoof Tile Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords