Home Appliance Applied CRCA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

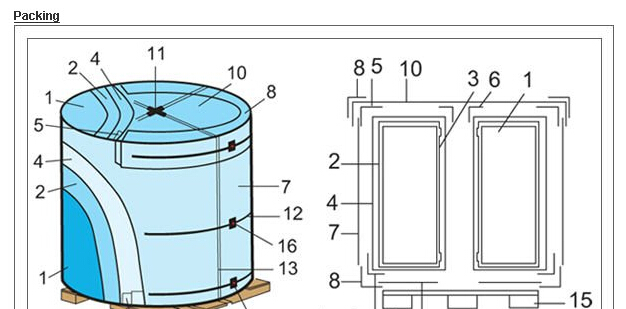

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Si | |

Q195 | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.04 | ≤0.30 |

Mechanical Properties

1. Yield Strength: ≤285MPa

2. Tensile Strength: ≤347MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 34%

(2) Nominal Thickness 0.25mm-<0.40: 36%

(3) Nominal Thickness 0.40-<0.60mm: 38%

(4) Nominal Thickness 0.60-<1.0mm: 40%

(5) Nominal Thickness 1.0-<1.6mm: 41%

(6) Nominal Thickness >1.6mm: 42%

- Q: What are the different types of steel products used in the manufacturing of outdoor furniture?

- The different types of steel products used in the manufacturing of outdoor furniture include steel tubing, steel frames, steel mesh, and steel plates. These steel products are chosen for their durability, strength, and resistance to weather and corrosion, making them suitable for outdoor use.

- Q: How does steel plate rolling work?

- Steel plate rolling is a manufacturing process that involves shaping and bending steel plates to achieve desired dimensions and curvature. The process typically involves passing the steel plate through a series of rollers that gradually apply pressure and force to manipulate the plate into the desired shape. The rollers exert force on the plate, causing it to elongate and bend, resulting in the desired curvature. This process is commonly used in industries such as construction, manufacturing, and shipbuilding to produce various components and structures made from steel plates.

- Q: What is the role of steel in the energy sector?

- Steel plays a crucial role in the energy sector as it is used in the construction of power plants, transmission towers, and pipelines. It provides strength and durability to these structures, ensuring their safety and longevity. Additionally, steel is utilized in the manufacturing of wind turbines, solar panels, and energy storage systems, enabling the production and distribution of renewable energy. Overall, steel is an essential material that supports the infrastructure and development of the energy sector.

- Q: What are the applications of steel mesh?

- Steel mesh has a wide range of applications in various industries and settings. It is commonly used in construction as reinforcement in concrete structures, providing strength and durability. Steel mesh is also utilized in the manufacturing of fencing, gates, and barriers for security purposes. It is employed in the automotive industry for seat frames, airbag deployment, and radiator grills. Additionally, steel mesh finds applications in filtration systems, animal enclosures, and even artistic installations.

- Q: How is steel wire galvanized for wire rope applications?

- Steel wire is typically galvanized for wire rope applications through a process called hot-dip galvanizing. In this method, the steel wire is first cleaned to remove any impurities. It is then dipped into a bath of molten zinc, which forms a protective coating on the wire's surface. The wire is then slowly withdrawn from the bath and cooled, resulting in a durable and corrosion-resistant galvanized steel wire that is suitable for wire rope applications.

- Q: What are the potential health hazards associated with working with steel products?

- Some potential health hazards associated with working with steel products include exposure to hazardous substances such as metal fumes, dust, and noise. Inhalation of metal fumes and dust can cause respiratory issues and lung diseases, while prolonged exposure to high levels of noise can lead to hearing loss. Additionally, cuts, burns, and other physical injuries can occur while handling steel products. It is important to use proper safety equipment and follow safety protocols to minimize the risks associated with working with steel products.

- Q: What are the common applications of steel products in the automotive industry?

- Steel products are widely utilized in the automotive industry for various applications. Some common uses include the manufacturing of car bodies, chassis, engine components, suspension systems, and various structural parts. This is primarily due to steel's exceptional strength, durability, and ability to be molded into complex shapes, making it an ideal material for ensuring safety, enhancing performance, and ensuring longevity in vehicles.

- Q: How is steel wire used in the manufacturing of springs?

- Steel wire is commonly used in the manufacturing of springs due to its high tensile strength and durability. It is typically formed into coils or helical shapes, allowing it to store and release energy when subjected to external forces. The steel wire is carefully selected based on its specific properties, such as diameter and strength, to meet the desired requirements of the spring.

- Q: How is steel wire galvanized for electrical applications?

- Steel wire is galvanized for electrical applications by immersing it in a bath of molten zinc. The wire is cleaned and then dipped into the zinc bath, which forms a protective coating around the wire. This process, known as hot-dip galvanizing, ensures that the steel wire is protected from corrosion and can be safely used in electrical applications.

- Q: What are the uses of steel gratings?

- Steel gratings have a wide range of uses in various industries and applications. They are commonly used as flooring and walkways in industrial plants, commercial buildings, and construction sites due to their durability and high load-bearing capacity. They also provide excellent drainage and ventilation, making them suitable for outdoor areas such as bridges, platforms, and stairs. In addition, steel gratings are used as safety barriers, security fencing, and protective coverings in manufacturing facilities and infrastructure projects. Overall, steel gratings are versatile and essential components that enhance safety, efficiency, and functionality in diverse settings.

Send your message to us

Home Appliance Applied CRCA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords