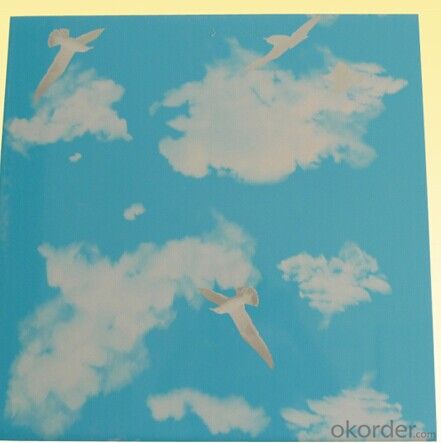

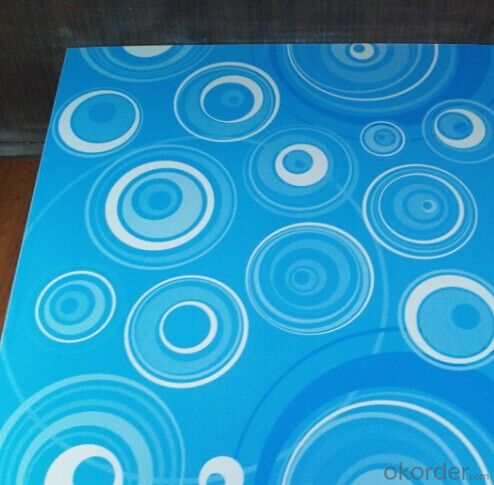

High Quality PVC Ceiling Panels B&Q (Popular PVC Ceiling Designs)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling ) Description

PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M

4.Advantage:Economic,Durable

2,Main Features of the (PVC Ceiling )

Main introduction of PVC Ceiling Panels

1.Thickness:5-12MM

2.Width:100-300MM

3.Length:It depends,like 5.8M,5.95M matching with the size of containers.

4.Type: Flat or with a groove in the middle of panels.

5.Contents of PVC panels: normal & popular PVC percentage is 40%, 45%, 50%, 55% or 60%, balance is calcium carbide or other carbonate.

6.Surface treatment:

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

PVC ceiling Frequently Asked Questions

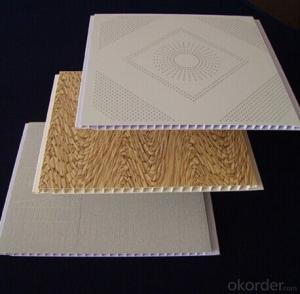

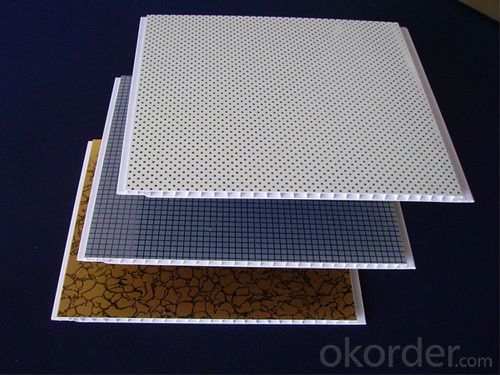

3,(PVC Ceiling ) Images

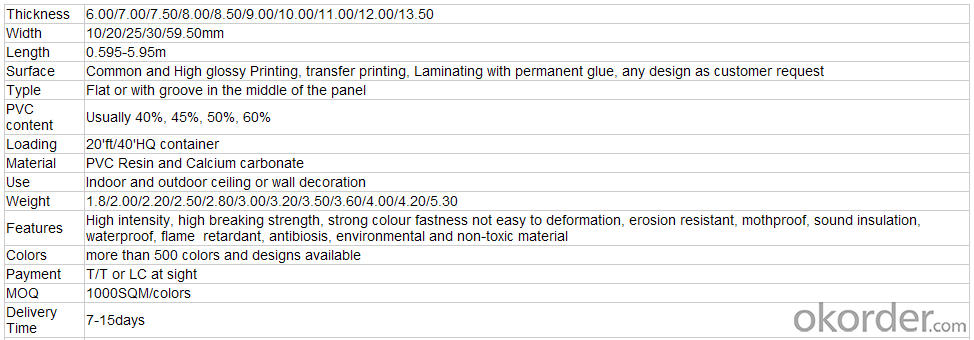

4,(PVC Ceiling ) Specification

4,(PVC Ceiling ) Specification

(1) Where are the ceiling panel applied?

The panels are designed for covering internal walls or ceilings in any room in the home or commercial rooms. Especially for the wet environment, such as the kitchen and the bathroom.

(2) How can I install the panels?

Our panels are designed to be installed by the DIY’S. We also provide you with the installation profiles. You just need very little experience and no special tools.

(3) What temperature range I can use plastic panels in?

PVC ceiling can withstand temperatures up to 140°F (60°C)

- Q: Pvc transparent board is building materials?

- Branch Po PVC transparent board: the product is the introduction of foreign advanced technology, the use of advanced imports of raw and auxiliary materials produced by a high-strength, high transparent plastic sheet. The product is high strength, high transparency, good weather resistance, non-toxic, health, physical properties better than plexiglass. Widely used in equipment protection board, interior, drinking water tank, liquid level display. Product color: white, sapphire blue, brown, brown and so on Product thickness: 2-20mm Maximum width of products: 1300mm Product Length: 100-10000mm Recommended Specifications: 1300 × 2000mm

- Q: Pvc wall board heat will produce toxic gas do

- Qualified normal PVC board temperature is not very high is not the distribution of toxic gases. It will change color for a long time. Only in the case of high temperature (melting above the temperature) will there be gas, but not all toxic, toxic gas is benzene.

- Q: How to pack the decoration pipe

- There are three general ways: 1, with pvc button board package. Cheap, easy construction, beautiful, life is not long. 2, with wooden keel backing, on the woodworking board, the last paste aluminum plate. 3, with 8 * 5 red brick puzzle, cement mortar, sticky steel mesh, and finally paste the tiles. More than 2,3 to be in the place where the need for inspection mouth.

- Q: Polyethylene board is not pvc board? If not, then what is the difference between the two? Thank you

- Polyethylene sheet is not PVC board. Polyethylene board, also known as low-pressure high-density polyethylene, HDPE board, PE board, HDPE rod. Is a high degree of crystallinity, non-polar thermoplastic resin. The appearance of the original HDPE was milky white, in a slight cross-section was a certain degree of translucent. Polyethylene sheet (HDPE board) melting point of about 130 ℃, the relative density of 0.941 ~ 0.960. It has good heat resistance and cold resistance, chemical stability, but also has a high rigidity and toughness, good mechanical strength. Dielectric properties, resistance to environmental stress cracking is also better. Melting temperature of 220 ~ 260C. For larger materials, the proposed melting temperature range between 200 ~ 250C. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. PVC board in the building materials industry accounted for the largest proportion of 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: PVC foam board on the market now uneven quality, is said to have a true crust and false crust, but do not know how to distinguish, and asked, Baotian Hi-Tech production of PVC crust foam board quality? Please tell you please.

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality belongs to the high-end

- Q: The building codes where I live are based on NEC codes. They're really hard to understand as a non-electrician.

- You only need conduit below the bottom of the joists or running down a concrete or block wall. If the NM cable is run along the joist or through holes in the joist if run across joists, no conduit needed. It does need to be stapled or otherwise supported every 4 feet. Where you need conduit, flex is okay.

- Q: Where do you have to sell the PVC board for the 2000x1200x20 specification?

- See your question for a long time no one to answer, but the question expired no one answered will be deducted and your reward points will be confiscated! So I'll give you a few suggestions: One, you can choose to ask questions in the correct classification, so that you will answer the question of the number of people will be more, the answer will be more people. Second, you can go to your question related professional website forum to see, where gathered a lot of professionals, we can solve the problem for you. Third, you can ask your online friends to ask friends, they will be more sincere and enthusiastic for you to find the answer, and even to the relevant site to search directly. Fourth, a lot of online professional forums and knowledge platform, there are a lot of information, I encountered professional problems is always on the forum to find a solution. Five, your question asked some fine, clear some! Make it easier to understand what it means to understand! Thanks for taking my advice!! /.,]]]

- Q: PVC decorative plate and clean plate difference

- Clean board more emphasis on the first two words, for the high quality requirements of the product. Application of the environment is more demanding areas. If you are decorating the office and home, I recommend you PVC trim panels over the clean board.

- Q: How heavy the pvc board hangs on the wall

- Pvc board weight is not too large, and only 0.6 square, can be used glass glue pvc board paste to the false wall. First in the pvc board around the diagonal and make a long glass of plastic, and then posted on the wall, surrounded by millet nails or clip fixed, two days after the glass gel dry remove the millet nails or clips can be. Later want to remove the pvc board painting, just use a small blade gently open the viscose of the hole, you can peel down, the wall of the remaining glass glue can also be stripped directly. Are you satisfied with the above?

- Q: Pvc board and pp board that is a lot of color, the kind of more suitable for kitchen and toilet waterproof furniture, furniture for the density of the board, specifications and other parameters are generally how much, about how much the price, China Province and the surrounding area Where can I buy this type of plate, the phone number is how much (I need is 1.5cm, 1.6cm and a small part of 1cm and 2cm of the plate)

- PP board: polypropylene (PP) plate, (PP pure plate, modified PP board, enhanced PP board, PP electrode) pure PP board: small density, easy welding and processing, with excellent resistance, heat resistance and Impact resistance, non-toxic, tasteless is the most environmentally friendly one of the engineering plastics. The main colors are white, microcomputer color, other colors can also be customized according to customer requirements. Applications: Acid and alkali equipment, environmental protection equipment, waste water, waste exhaust equipment, scrubbers, clean rooms, semiconductor plants and related industrial equipment, but also the preferred material for the manufacture of plastic water tanks, PP thick plate widely used for stamping Plate, punch and so on. Pvc board: polyvinyl chloride (PVC) plastic is a vinyl chloride monomer by free radical polymerization of the polymer, the English name polyviny chloride, referred to as PVC. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

Send your message to us

High Quality PVC Ceiling Panels B&Q (Popular PVC Ceiling Designs)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords