high temperature resistance bio-soluble ceramic fiber paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Bio-soluble ceramic fiber paper is paper-shape high-temperatur resistant products which compose of undirectional soluble fiber blended with a spot of organic viscose.

Application:

Processed to sealing and gasket for the high temperature part;

Filtration for high temperature gas;

Thermal insulation and insulation for all kinds of appliance and heating equipment.

Product Capability:

New type,low -carbon,energy-saving,environmental protection,no pollution,no carcinogenic material was included;

Good thermal stability,unaffected by thermal shock;

Block infra-red radiation;

Good corrosion resistance;

Good fiber flexibility;

Biogradable,industrial wastes do not have to deal with.

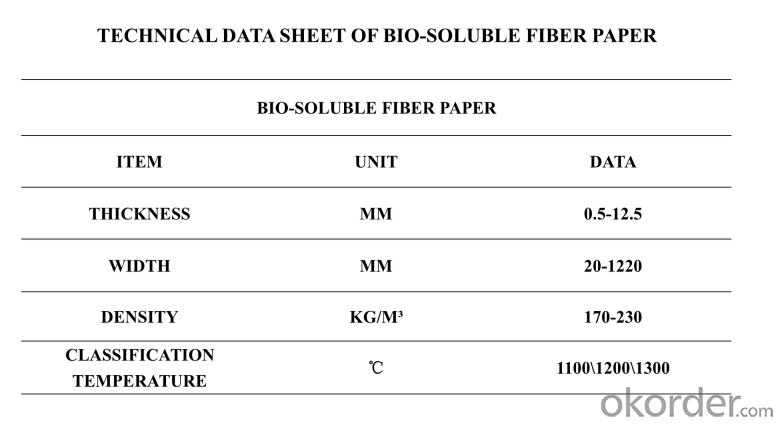

Data Sheet:

Bio-soluble Fiber Products:

This new type of refractory material is in comply with the rules which declared by the EU that hazardous material is fobidden or limited to be used (EU/EC) declaration).It can be resolved in biological body,contains no carcinogens and harmless to human body.

- Q: Slag ball content of ceramic fiber material?

- Effect of slag ball content on ceramic fiber materialSlag ball content ceramic fiber products is an important factor that affects the bulk density. Slag ball density in 2800 ~ 3200kg/m fand, excessive slag ball content fiber products, comprehensive energy-saving performance will reduce the ceramic fiber blanket, ceramic fiber module of ceramic fiber products, and damage the interests of users.

- Q: Brief introduction of ceramic fiber cloth

- - Product Description -Ceramic fiber cloth is made of heat-resistant gold wire or non alkali glass yarn reinforced spun wire ceramic fiber yarn. The ceramic fiber cloth has high strength, good flexibility and processability. It not only has high temperature insulation property, but also has the flexibility of ordinary textile. Fire retardant clothing, fire blankets, insulation and other industrial and civilian fire insulation products.- Product Categories -Fiberglass reinforced ceramic fiber clothHLGX-208A1 (glass yarn reinforced)Wire reinforced ceramic fiber clothHLGX-208A2 (heat resistant stainless steel wire reinforced)- product characteristics -Good high temperature tensile strengthGood electrical insulation performance? good acid, oil, water vapor corrosion resistanceLow thermal conductivityGood insulation performanceNo asbestos, non-toxic and harmless, no adverse effects on the environment- typical applications -Equipment, instruments, high temperature protection, removable insulation, apply raw materialsThermal insulation and thermal radiation shielding of high temperature pipes and containersIndustrial furnace door sealing, large equipment insulation gasketIron and steel industry continuous casting and rolling fire curtain curtain? fire shutter, labor protection clothing, fire protection clothing, household and commercial fire fighting blanketCable or fuel line protectionHigh temperature resistant metal compensator, refractory layer, soft connection of high temperature pipeline- technical indicators -Ceramic fiber clothClassification temperature (DEG) 1260Product code HLGX-208A1 HLGX-208A2Use temperature (DEG) 6501000Basic material: ceramic fiber / glass fiber reinforced ceramic fiber / wire reinforcedThe theory of volume density (kg/m 500 + 15 fand)Regular size (mm) 30000 * 1000/2200 * 2/3Moisture content (%) = 2The meridional density is 56 ~ 60piece/10cmThe zonal density is 24 to 30piece/10cmCauterant (%) = 15Plastic bag, outer woven bag

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is the customs code for ceramic fiber products?

- The customs code should be 6914.9000Specific can be seen by the Chinese customs published in 2005 edition of import and export commodity names and codes, thirteenth and sixty-ninth chapters, ceramic products, P166-168 pages.

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q: What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: The characteristics of ceramic fiber paper

- Ceramic fiber paper, aluminum silicate fiber paper, also called refractory fiber paper.Classification of ceramic fiber paper:Standard ceramic fiber paper HLGX-236High alumina ceramic fiber paper HLGX-436Ceramic fiber paper containing zirconium HLGX-536

- Q: What is the use of ceramic fiber paper?

- Mifso-14 ceramic fiber paper gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced. Can be customized by users to produce sizes.

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- When choosing ceramic fiber, aluminum silicate fiber products,1, according to the use of temperature to choose,1050, ordinary ceramic fiber, aluminum silicate fiber, suitable for 850 degrees Celsius temperature insulation1260 standard ceramic fiber aluminum silicate fiber, suitable for 1000 degrees Celsius temperature insulation1260 high purity ceramic fiber, aluminum silicate fiber, suitable for 1100 degrees Celsius temperature insulation1400 high alumina ceramic fiber aluminum silicate fiber is suitable for 1200 degrees Celsius temperature1400, zirconium containing ceramic fiber, aluminum silicate fiber, suitable for 1280 degrees Celsius temperature insulation

Send your message to us

high temperature resistance bio-soluble ceramic fiber paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords