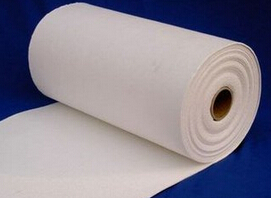

High-Temperature Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of High Temperature Paper

1.Uniform thickness and smooth appearance;

2.Contains no asbestos and anticorrosion; No action with aluminum fluid;

3.Low heat storage;

4.Low thermal conductivity;

5.Good flexibility and toughness and resistance to avulsion;

6.Excellent chemical stability;

7.Excellent machining property;

8.Excellent electric insulation and sound insulation;

9.Excellent thermal shock resistance

Typical Application of High Temperature Paper

1.Appliance heat seals

2.Parting plane in refractory linings

3.Combustion chamber liners

4.Backup lining for metal troughs

5.Hot top linings

6.Thermal and electrical insulation

7.Refractory backup insulation

8.Coke oven door shook absorption medium

9.Kiln car deck covering

Technical Data of High Temperature Paper

Grade | Standard | High Pure | High Aluminium | Zirconium | |||

Max. Temperature (°C) | 1050 | 1150 | 1260 | 1430 | |||

Shrinkage on Heating (%) | 800°C×24h≤-3 | 1000°C×24h≤-3 | 1280°C×24h≤-3 | 1400°C×24h≤-3 | |||

Organic Content (%) | ≤5 | ≤5 | ≤5 | ≤5 | |||

Thermal conductivity by mean temp. (W/m.k.) (250kg/m3) | 200°C | 0.055~0.065 | 0.060~0.070 | ||||

400°C | 0.110~0.120 | 0.105~0.125 | |||||

600°C | 0.160~0.170 | 0.170~0.180 | |||||

Chemical Composition (%) | AL2O3 | 43 | 47 | 55 | 38 | ||

SiO2 | 53 | 51 | 44 | 44 | |||

Fe2O3 + Ti2O3 | ≤1.2 | ≤0.3 | ≤0.3 | ≤0.2 | |||

CaO + MgO | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.2 | |||

NaO + KO2 | ≤0.5 | ≤0.3 | ≤0.3 | ≤0.2 | |||

Density (kg/m3) | 170~230 | ||||||

Size (mm) | Length: 60000/40000/30000/20000/15000/12000 Width: 1220/610 Thickness: 1~6 (Other sizes and shapes on request. ) | ||||||

Package |

Carton box | ||||||

Certificates |

ISO9001-2000; ISO14001-2000 | ||||||

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- Ceramic fiber paper is made from high purity ceramic fiber and a small amount of binding agents which are scientifically selected and tightly controlled. The wet vacuum forming process makes the fiber distribution very uniform, and the thickness and volume density of the aluminosilicate fiber paper can be strictly controlled. The binder will be completely ablated during use.

- Q: Is the slag ball of the ceramic fiber useful?

- Slag balls are basically useless, just like raw ore.

- Q: What's the fire resistance of the ceramic fiber?

- Because of the low heat conductivity, small density and light weight of the fiber, the light steel support structure is adopted in the design and construction of the kiln, which makes the development of the ceramic kiln into the lightweight era of the kiln. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. The ceramic fiber products are: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range of 8711427 DEG C, under special circumstances can be short-term use in the high temperature limit temperature above the.

- Q: Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- The concept of electrical conductivity in physics, in which the product of the quantity and the electric field intensity is equal to the conduction current density. For isotropic media, conductivity is scalar; for anisotropic media, conductivity is tensor. In ecology, conductivity is the ability to conduct current by means of a numerically expressed solution. The unit is expressed in SIEMENS per meter (S/m). The conductivity is simply the product of the measured conductivity (G) and the conductance cell constant (L/A). Here the L is the length of the liquid column between two plates and the A is the area of the plate. P l=l/ = sigma (1) definition or explanation for the reciprocal of resistivity conductivity. Sigma Rho =1/ (2): units in the international system of units, the conductivity of the unit is SIEMENS / m. (3) the physical meaning of conductivity is to indicate the conductivity of a substance.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- Ceramic fiber paper, with its superior product characteristics, has gained high status in the field of industrial high temperature insulation. It is generally used as insulation, heat preservation, sealing, electrical insulation, sound-absorbing and filtering materials. The utility model can be used not only as the inner wall of the lining, but also as the sealing material of the heat insulation material and the high temperature appliance, and can be used as the good heat insulation and cold protection material of the refrigeration equipment of the refrigerator.Ceramic fiber paper is widely used in various industrial furnace and ladle, ladle, submerged nozzle for high temperature heat insulation material; and industrial electric motor insulation and thermal insulation materials, sealing materials door and furnace expansion joints, in some high temperature instruments, equipment can also be used as insulation material; at the same time in the glass ceramics and heat melt glass film removing glass used as demoulding. Ceramic fiber paper has good sound insulation, noise reduction and noise reduction performance, so it can be used for silencer, insulation and insulation material of automobile exhaust pipe. Dragon Fire energy saving.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) (1) ceramic fiber products (aluminum silicate fiber products) varieties and properties of ceramic fiber products (aluminum silicate fiber products) is the most important indicator of fiber diameter and thermal stability. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance. Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Glass fiber has low temperature resistance, preferably not higher than 550 degrees, and ceramic fiber has good temperature resistance.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Two ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, both can be used for insulation and heat preservation

- Q: What's the difference between ceramic fiber paper gasket and ceramic fiber gasket?

- Surface: HLGX ceramic fiber paper gasket, surface smoothness, good sealing, HLGX ceramic fiber cloth gasket surface grid shape, has certain permeability.

- Q: What fiber glass made of ceramic fiber paper?

- Ceramic fiber paper production process is:Beat out - pulp - pulp - long mesh forming - vacuum dehydration - drying - cutting - winding - packaging

Send your message to us

High-Temperature Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords