High Purity Heat-Resistant Ceramic Fiber Paper DZ

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High purity heat-resistant ceramic fiber paper STD

The general information of ceramic fiber paper

Paperis CMAX ceramic fiber made from high quality she clay, high purity alumina and silica oxide by rotating or blowing process. Asbestos is free. Double needle provide Paperwith great tensile or strength, ease of installation.

Products have been classified as a sexually transmitted disease, HP, ha, and hz, respectively corresponding to different maximum operating temperature 1000 ℃, 1100 ℃, 1200 ℃ and 1350 ℃

The properties of the ceramic fiber paper

Heat resistance

Light weight

Low coefficient of thermal conductivity

Low heat storage

To adapt to the thermal shock

High tensile strength

The application of ceramic fiber paper

Petrochemical process heating refractory fiber lining

Heat treatment furnace or intermittent kiln lining (shuttle) hot face

General backup furnace insulation

Heat sealing kiln car or oven door

Electrical insulators

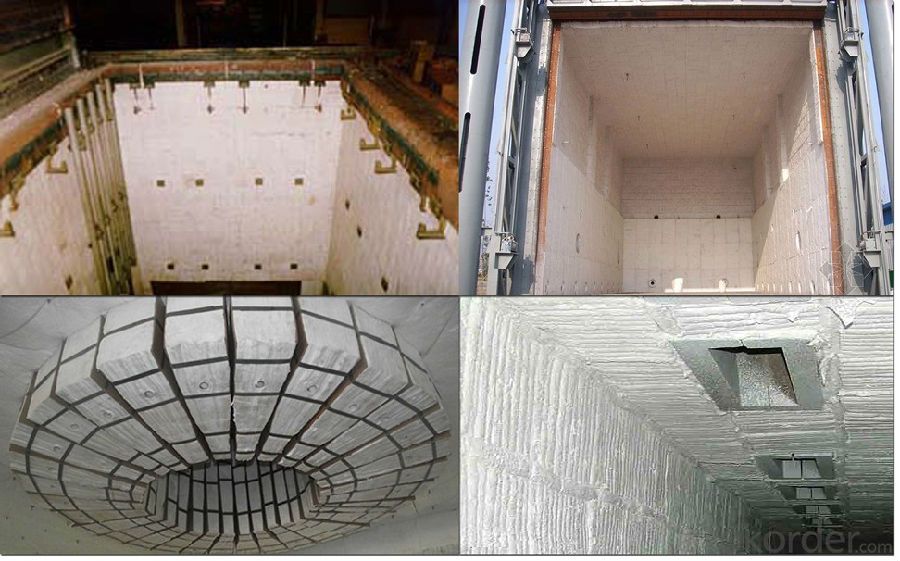

Pictures of ceramic fiber paper

FAQ

1. What are your products?

We have all kinds of refractory brick, slurry, mortar, cement, ceramic fiber products, etc.

Or you can browse our product to choose what you need.

2. How to control the quality of the product?

Have a strict quality control system in the process of material selection and production, our refractory material and ceramic fiber effective control of product quality to meet customer demand.

From the selection of raw materials, our quality control. The quality of the raw material certificate is required, each batch will be tested before use. In the process of production, quality control is made up of workers, then each classification, quality supervision and inspection.

3. Can you give me a brief introduction of the application of your products?

We mainly specialized in refractory steel, cement, glass, ceramics, oil chemical, electric power industry, etc.

4. If I need your quotation, what information do you need?

In order to choose the right product, will be appreciated

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q: Is the slag ball of the ceramic fiber useful?

- Slag balls are basically useless, just like raw ore.

- Q: What are the materials for making ceramic fibers?

- Ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity and heat resistance of small and mechanical shock and other interests, so in the machinery, metallurgy and chemical industry, petroleum, ceramics, glass, electronics etc. have been widely used.

- Q: The condition of ceramic glass fiber at high temperature

- Generally speaking, the glass fiber has low temperature resistance, and the biggest use is glass fiber reinforced plastic; the ceramic fiber has higher temperature resistance, and the biggest purpose is to be used as the structural material of refractory bricks, but generally it does not form fabric;

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- Solid energy saving STP insulation board, its insulation performance than traditional ceramic fiber insulation material is better than 3~4 times

- Q: Can ceramic fibers be spun into fibers, please?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun

- Q: Do ceramic fiber paper smell at high temperature?

- If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What are the features of ceramic fiber gaskets?

- Mifso-11 ceramic fiber gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.

Send your message to us

High Purity Heat-Resistant Ceramic Fiber Paper DZ

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords