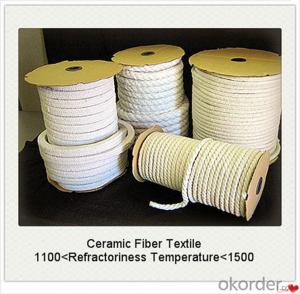

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Ceramic fiber cloth

2.1260C

3.thickness:1-5mm

4.reasonable price

High temperature ceramic fiber refractory fabric for heat insulation

Specifications:

Temperature:450C-1260C

Thickness:1.5mm-6.0mm

Width:500mm-1200mm

Density:500kg+/-30kg/m

Reinforcing materials: glass fiber wire, stainless steel wire

1. Products Details:

Hitex Ceramic Fiber Cloth is a woven fabric made from our high quality ceramic fiber woven yarn. The cloth is reinforced with fiberglass filament, or optional Inconel/alloy steel wire reinforcement. It is featured with heat insulation and high temperature protective materials in all kind of thermal installations and heat-conducting systems, widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, shipyards, refineries, power plants and chemical plants.

2. Product Advantages:

1.Resistance to high temperature and chemical erosion

2.High mechanical strength

3.Low thermal conductivity

4.Low thermal storage

5.Resistance to heat shock

6.Easy installation

3. Technical Data:

Item | Ceramic Fiber Cloth | |

Classification Temperature | 1260C | 1260C |

Work Temperature | 450C | 1000C |

Basic Material | Fiberglass Reinforced | Stainless Steel Reinforced |

Theoretical Density ( kg/ m3) | 500±15 | |

Moisture Content (%) | ≤2 | |

Warp Density | 48~60 Piece/10cm | |

Weft Density | 21~30 Piece/10cm | |

Organic Content (%) | ≤15 | |

Specification (mm) | L:30,000mm / W:1,000mm / T:2~3mm | |

Packing | Plastic bag inside, woven bag outside | |

- Q: Is recycled glass recycled high in value? What's the value of it?

- Yes, it can be made into ornaments, such as rabbits, or fruit, and so on

- Q: Can glass fiber textile be used in oil and gas pipelines?

- Indeed, glass fiber textiles possess the capability to be utilized within oil and gas pipelines. Renowned for their exceptional robustness and resistance to corrosion, glass fiber textiles prove to be suitable for a multitude of applications within the oil and gas sector. By serving as reinforcement within composite pipes for oil and gas pipelines, glass fiber textiles effectively amalgamate the strength of glass fiber with the corrosion resistance of alternative materials like epoxy or thermoplastic resins, thereby engendering a pipeline solution that is both enduring and long-lasting. The utilization of glass fiber textiles within oil and gas pipelines yields the advantage of diminishing the likelihood of corrosion and augmenting the overall lifespan of the pipeline, thus rendering it a pragmatic choice for the industry.

- Q: Can glass fiber textiles be used in reinforcement of silk fibers?

- Indeed, glass fiber textiles have the potential to reinforce silk fibers. Renowned for their immense strength and durability, glass fiber textiles are an ideal choice for bolstering other materials. When melded with silk fibers, which offer a plush and opulent touch, the resultant composite can reap the advantages of both materials. The glass fiber textiles function as a reinforcement, imbuing the silk fibers with added strength and rigidity, thereby rendering the overall material more resilient and less prone to tearing or fracturing. This proves especially advantageous in situations where silk fibers alone may not offer adequate strength, such as in the creation of fabrics for robust garments or textiles utilized in industrial settings. Furthermore, glass fiber textiles can heighten the dimensional stability of silk fibers, curtailing the potential for shrinkage or elongation over time. By amalgamating these two materials, the resulting composite can retain its form and integrity for lengthier periods, thereby augmenting its longevity and durability. Nonetheless, when employing glass fiber textiles to reinforce silk fibers, it is crucial to consider the specific requirements of the application. Factors such as the compatibility between the two materials, as well as weight, flexibility, and breathability, must be taken into account to ensure the desired performance characteristics are attained. To sum up, glass fiber textiles can indeed be employed to reinforce silk fibers, augmenting their strength, durability, and dimensional stability. This combination can prove particularly advantageous in scenarios where silk fibers alone may fall short of meeting the necessary performance standards.

- Q: What kinds of fiberglass mesh do you have?

- Glass fiber mesh cloth, also called fiberglass mesh, mesh cloth, heat insulation, it can be divided into standard type glass fiber cloth, glass fiber cloth reinforced, flame retardant glass fiber mesh and self-adhesive fiberglass mesh cloth four.

- Q: Can glass fiber textiles be used in marine applications?

- Glass fiber textiles are indeed applicable for marine uses. Renowned for their remarkable strength, durability, and ability to resist corrosion, these textiles prove to be a fitting material for a wide range of marine applications. It is commonplace to utilize them in the construction of boats, yachts, and other marine vessels, as their considerable tensile strength and lightweight nature are highly coveted qualities. Moreover, the manufacturing of marine equipment, including hulls, decks, and components demanding outstanding strength-to-weight ratios, also benefits from the utilization of glass fiber textiles. Furthermore, their resistance to water and chemicals renders them an optimal choice for marine applications where exposure to such elements is prevalent.

- Q: Can glass fiber textiles be woven?

- Indeed, it is possible to weave glass fiber textiles. Fiberglass, or glass fiber, is a highly adaptable substance that can undergo diverse transformations, including the creation of textiles. Generally, glass fibers are produced by extruding liquid glass through fine nozzles, resulting in delicate glass filaments. These filaments are subsequently interlaced utilizing conventional weaving methods to generate glass fiber textiles. These textiles possess remarkable qualities, including robustness, lightness, and exceptional resistance to heat and chemicals. Consequently, they find widespread utility in numerous applications, such as insulation, reinforcement in composite materials, and the production of various items, including garments, drapes, and furniture upholstery.

- Q: Can glass fiber textile be printed on?

- Glass fiber textile can indeed be printed on. To print on glass fiber textile, one must apply ink or dye onto the textile's surface using different printing techniques like screen printing, digital printing, or heat transfer printing. However, it is crucial to acknowledge that successful printing on glass fiber requires special inks, dyes, and printing techniques due to its smooth and non-absorbent properties. These specialized materials and techniques guarantee proper adhesion and long-lasting prints on glass fiber textiles.

- Q: Are glass fiber textiles resistant to wear and tear?

- Yes, glass fiber textiles are highly resistant to wear and tear. Due to their strong and durable nature, they can withstand repeated use and exposure to various environmental factors without losing their integrity or performance.

- Q: What are the ingredients of glass and plastics?

- The glass was originally solidified by acid lava ejected from the volcano. About 3700 BC ago, the ancient Egyptians had made glass ornaments and simple glass ware, only colored glass, about 1000 BC, China made colorless glass. In twelfth Century ad, commercial glass appeared and began to become industrial materials. In eighteenth Century, optical glass was fabricated in order to meet the needs of developing telescopes. In 1873, Belgium first produced flat glass. In 1906, flat glass was produced in the United states. Since then, with the industrialization and large-scale production of glass, various uses and various properties of glass have come out. In modern times, glass has become an important material in daily life, production and science and technology.

- Q: Can glass fiber textiles be used in reinforcement of bio-based composites?

- Glass fiber textiles are capable of being utilized for reinforcing bio-based composites. Their high strength and stiffness make them a popular choice for reinforcing materials. Glass fibers effectively reinforce composites and enhance their mechanical properties. In the case of bio-based composites, the inclusion of glass fiber textiles aids in improving the material's overall strength, durability, and performance. Moreover, the amalgamation of bio-based materials and glass fibers presents a more sustainable and eco-friendly substitute for conventional composites.

Send your message to us

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords