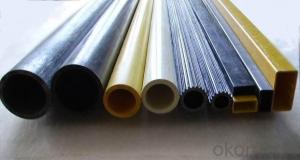

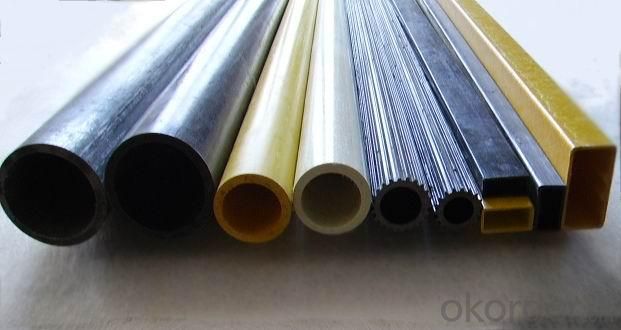

High Strength Composite FRP/GRP Pipes Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introdiction

FRP Pultrusion profile is a kind of composite which made by reinforced fiberglass materials (fibers, mat,etc.) and combination withresins and other auxiliary materials(binders). It has very excellent characteristics such as high temperature resistance, corrosion resistance, high strength, light weight, low moisture absorption, good insulating, large-span etc.Pultrusion profiles has very high designability, it can be made into diverse FRP products by appropriate connection and combination of various kinds shaped pultrusion profiles, and it is widely used in different fields such as light industrial products, construction platform, handrail, crawling ladders, pedestrian walkways, cable bridge, cooling tower support, electrotechnical products, etc.We can supply many kinds of FRP pultrusion profile such as Angel beam, I beam, U channel, round tube/rod, square tube, rectangular tube, solid rod, other special shaped profiles etc, and we can also make customized designs.

2.Product Features:

1. High strength.

2. Light weight.

3. Excellent corrosion resistance.

4. Good electric insulating.

5. Fire resistance.

6. Structurally strong.

7. Anti-aging and low maintenance.

8. Easy to fabricate and install.

9. Various Colors available.

10. High designability, can make customized designs.

11. Cost-effective.

3.Specifications

1) adopted the glass fiber and products as its reinforced material,

2)saturated polyester resin as its body material,

materials:

3) adopted the glass fiber and products as its reinforced material,

4)saturated polyester resin as its body material,

5)sand as its filler and equipped with the stipulated length winding technique,

features:

6)lightness and high strength,

7)distinguished properties of water-fast and corrosion resistance,

8)excellent hydraulic property,

9)good hermetical property of joint without poison.

Application:

1) for water -leading projects

2) reduction of the transportation cost and therefore ensured the high quality of the drinkable water.

3)sewage pipes,rainwater pipes

Diameter: DN300-4000

Pressure: PN6-25

Rigidity level: SN2500-10000

Length: 6m, 12m

4.Pultruded Fiberglass Pipe, FRP pipe, GRP pipe of high strengh

The fiberglass reinforced plastic rod is made from high strength glass fibers along withextremely durable resin. The glass fibers impart strength to the rod while the resin impartsexcellent corrosion resistance properties in harsh chemical and alkaline environments.

5.Advantages

1) Long Working life

2) Light weight

3) High strength

4) Good flexibility

5) Beautiful appearance

6)Good Insulation

7) Corrosion resistance

8) Good comprehensive benefits.

- Q: What are FRP pipes made of?

- Length of single pipe lengthReduce pipe connection, speed up installation, improve the quality of the whole pipeline.

- Q: What can be done to solve the leakage of FRP pipe?

- If you can't get into the pipe, polish it from the outside and polish it to the lining. Then make a new lining, and then use a cloth to reinforce the structure.

- Q: What are the main materials used for steel pipes?

- General: steel duct (ordinary steel), galvanized plate (Bai Tie) wind pipe, stainless steel pipe, glass steel ventilation ventilation pipe, plastic pipe, composite pipe ventilation ventilation, ventilation pipe, sandwich insulation board rubberized cloth ventilation tube (such as mine, mine ventilation duct) plastic pipe; ventilation pipe by use of points: General: purification system air supply pipe, central air conditioning and ventilation pipe, industrial ventilation ventilation pipe, suction duct, environmental protection system for mine gas drainage pipe, mine ventilation pipe coating cloth duct; according to the shape: General: round, rectangular, spiral etc.;

- Q: Which is better, PVC pipe and GRP pipe?!

- Depends on location, and design requirements. Nowadays FRP is in the majority.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Glass fiber reinforced plastic words, such as what you said, for ordinary construction workers, a little difficult, after all, opening and bonding can not do under high pressure or long-term use of water leakage.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- General glass fiber reinforced plastic, no corrosion protection.If buried with epoxy coal pitch can be, anti rust grade Sa2.5, six oil four cloth can.

- Q: What's the price of fiberglass reinforced sand pipes?

- It must be different. It costs a lot of freight, so I suggest buying it locally. Henan is in Henan.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Ensure the solidification of glass steel products in a reasonable range, in general, glass fibre reinforced epoxy resin material curing degree if the use of amine curing agent, the best curing degree in the range of 135 degrees --150 degrees, polyester resin, Mohs hardness of about 60 is OK.

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- Glass reinforced plastic underground sand pipe has long service life without operation and maintenance, which is the biggest advantage of this product. Since pipe jacking is an underground concealed project, its service life is undoubtedly the very important consideration of decision-makers. The service life of glass fiber reinforced plastic sand pipe jacking is more than 50 years, which is incomparable to the products such as steel pipe, concrete pipe and so on.

Send your message to us

High Strength Composite FRP/GRP Pipes Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords