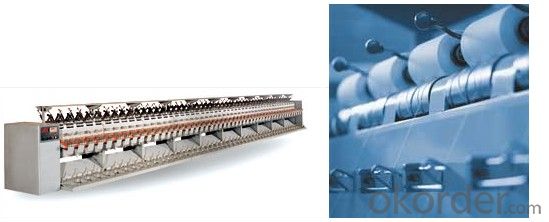

High Speed Cone Rewinder Machine for Rewinding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Structure of High Speed Cone Rewinder Machine:

Shafting: vertical tensioner & waxing unit

Creel pressure balance device:Ni-P alloy grooved drum & motor

Single spindle controller: The transverse regulating system

Automatic tube filling machine:the conveyor of tubes

Description of High Speed Cone Rewinder Machine:

High Speed Cone Rewinder Machine is used for winding yarns on cones.

Application:

High Speed Cone Rewinder Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

Main Features:

High Speed Cone Rewinder Machine has the following advantages:

· Vertical winder path with no inflection,little friction and less hairiness.

· Converient to adjust the speed of single spindle. It can provide different winding speed for various yarns.

· Double points waxing system with micro motors, waxing steady and uniform. The forming of cheese is better.

Using high quality alloy drums with optimized groove shape ,which has the advantages of good anti-overlapping characteristics, light weight,good wear resistance, and static elimination.

Single winding motor control for each spindle, single spindle automatic stop while yarn breaking or fully filled.

Images of High Speed Cone Rewinder Machine:

Specification:

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

| Package shape | Cylindrical or conical packages |

| Traverse length | 147mm,150mm,154mm |

| External dimensions | 13410mm(length) ×700mm(width) ×1680mm(height) |

| Power supply | 3 phased 380V±10% ,50/60HZ |

| Automatic length fixing | Automatic length fixing,max:999999m |

FAQ of High Speed Cone Rewinder Machine:

· Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- In the process of transformation from the workshop to the large industrial machinery industry, due to the further development of the enclosure movement, the majority of the farmers lost the land to survive, they had to wander to the city to make a living

- Q: What is the second-hand textile machinery import clearance process?

- 1. Used equipment, but to maintain its basic use value or the full use value

- Q: How does the mechanical wave generated in the spinning process work?

- Mechanical waves meet, you can cross each other, do not interfere with each other

- Q: What is the current status of the textile industry?

- China is the textile production and export power, China's textile industry itself after years of development, competitive advantage is very obvious, with the world's most complete industrial chain, the highest level of processing support, many developed industrial clusters to deal with market risk self-regulation The ability to continuously enhance the industry to maintain a steady pace of development provides a solid guarantee.

- Q: What are the main producing areas of Chinese textile machinery?

- While the southern Jiangsu and Zhejiang, mainly textile mills more, but there are many textile machinery manufacturers

- Q: What is the chenille mechanical principle?

- Its production and processing products called chenille yarn or spiral, broken wire, is a new variety of fancy

- Q: What is the textile process?

- , clear cotton process: to remove most of the raw cotton impurities, defects and not spinning short fiber.

- Q: What are the mechanical characteristics of textile machinery?

- n modern times, people's understanding of the structure and physical and chemical properties of fibers is deepening, thus creating more and more advanced process methods, which can more fully play the characteristics of fiber and fabric. In line with this development, modern textile machinery using mechanical technology, electrical technology, especially weak technology to create a wide range of different performance processing machines. For example, the industrial coating fabric preparation process coating method, roll method and lamination method, the design of the machine also has three different structures accordingly. Another example is the high affinity (130 ° C) and high pressure (2.7 kg / cm) dyeing equipment that can reduce the dyeing time and achieve good dyeing fastness.

- Q: Textile machinery production process is probably what kind of?

- Carding parts of a wide variety of materials, many shapes, but generally is the first processing parts, according to the requirements of the drawings, in addition to the requirements of the part of the preparations are nothing more than casting and forging, welding pliers and so on.

- Q: China's textile industry prospects of printing and dyeing ?

- Prospective Industry Research Institute released the "China Textile Machinery Manufacturing Industry demand and investment forecast analysis report" shows that China's textile machinery manufacturing industry in recent years to maintain rapid development momentum.

Send your message to us

High Speed Cone Rewinder Machine for Rewinding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords