High Quality Low Carbon stone 001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of low carbon stone

|

Raw material |

Sawdust, corn-straw and tailing, can be recycled after using. |

|

Technology |

Utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. |

|

Installation |

Stitching, wet-sticking and dry-fasten connecting |

|

Character |

Favorable corrosion resistance, non-ignitable, water-proof, UV-resistant, high resistance to fire, water and insects. |

|

Lead time |

30 days after receiving buyer's original L/C or Prepayment |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Four breakthroughs |

Comprehensive utilization of natural resources: Be recyclable, using sawdust, corn-straw and tailing as materials. The product can be recycled after using. |

|

Low carbon and energy saving in the course of production: Adopting the independent individual property’s technology, utilizing molecular structure of crystalline-state solidification, shaping under normal temperature and pressure with low carbon emission. | |

|

Environmental and healthy in the course of construction and using: Synthesized by natural inorganic raw materials, nontoxic, odorless and non-radiative simple installation, which could save energy cost and reduce and waste emission, raise efficiency and reduce erection time. | |

|

From nature, beyond nature: Full realization of the natural texture, high resistance to fire, water and insects. Do not rot or fade after long time usage. Super self-cleaning needs low maintenance cost. Vivid color and appearance provides a wide space to designers. | |

|

Six advantages |

Lower more than 50% cost, enhance building's performance to price ratio. |

|

Cutting at will, Fixing easy, Shorting project time. | |

|

Good performance in resistance to elements, corrosion-resistant ,resistance to termite, fire resistance and water-resistant, far from distortion and discolorations in 30 years. | |

|

Well self-cleaning, low cost in later maintenance: Don't need professional maintenance in 30s(Cleaning with water only), saving much cost. | |

|

Customize the color, showing individuation: Beyond 400 kinds of colors, designers could exhibit their imagination. | |

|

Compound with natural inorganic materials: Without formaldehyde and toluol, sustained releasing negative oxygen ion, forming nature oxygen bar. | |

|

Special specifications are available on customers' requirements. | |

Technical information of low carbon stone

|

Density |

1.23 g/m3 |

Folding strength |

15.4 Mpa |

|

Wet expansion rate |

0.32% |

Shear strength |

3.5Mpa |

|

Frost resistance |

Thaw-freeze cycle after 25 times, no slip crack and peeling off | ||

|

Formaldehyde release |

0.014mg/(m2·h) (GB/T 18587-2001) | ||

Specification of low carbon stone

Standard: 2400mm/3000mm(L)×1200mm(W)×12mm/20mm(T)

Standard length: 2400mm/3000mm

Standard width:300mm,400mm,600mm(including 3mm kerf width)

Standard thickness: 12mm/20mm

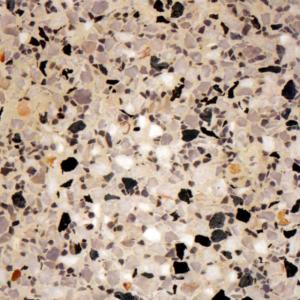

Product exhibition of low carbon stone

Low carbon stone with hole rock

Low carbon stone

The project picture of low carbon stone

- Q: Highlight artificial stone cleaning method

- For those stubborn dirt, you need special care. Sponge and non-abrasive brightener. Especially difficult to remove the dirt, can be used 1200 mesh sandpaper polished, and then use soft cloth and light agent to make it bright. Artificial stone sink: with decontamination detergent and water. Often use 1: 1 bleach solution soak 10-15 minutes, then wash the bottom with water and around.

- Q: How to repair man-made stone

- If it is used for a long time, scratches more, you can ask the professional man-made stone master to your desk to polished polished renovation.

- Q: Artificial stone countertop or natural marble countertop good?

- This is both easy to clean, but also bear a certain weight, but also play a good decorative effect. Natural marble surface generally small fine cracks, grease easily immersed in the stone caused by pollution, its surface bearing capacity is poor, and there is radiation pollution, especially the deep red natural marble, more radiant. Artificial stone processing process through the crushing process, re-use at high temperature and high pressure using special adhesive to suppress the internal structure of dense, grease can not be dipped, easy to clean, its high bearing capacity, radiation pollution is very small. From the performance point of view, artificial stone countertop is better than the natural marble countertops. But the natural marble has a natural texture and charm, decorative good, cheap. Artificial stone texture uniform, slightly less decorative, the price is higher. It is recommended that you decorate the use of artificial stone kitchen counter to the countertop, after all, many of its performance is much better than natural marble.

- Q: Big windowsill artificial stone countertops below without any support, how reinforcement

- The following is paved should not be trampled like things happen, if your windowsill is not flat, you can consider the windowsill on the bench to remove the cement layer, the wood board 1.8 or MDF 1.2 tile in your windowsill , And then the table on the board, so there will not be much problem, but if your table out of the wall too much, more than 5 cm above, then you need to do iron angle bracket, or will crack open! Hope to adopt!

- Q: Artificial stone how to remove the plastic

- Artificial stone mainly to look at the next type of installation is left or otherwise, if it is installed when the first to eradicate the thicker place after the use of acetone to clean up. Note that when wiping with a good glove, because acetone is a chemical easy to damage the skin.

- Q: Artificial stone under the basin how to use screw hook fixed

- Bonding method, but also to use flexible adhesive sealant (such as modified silane adhesive sealant, commonly known as MS glue), while bonding and sealing. After curing a certain degree of flexibility, can accommodate thermal expansion and contraction, anti-vibration, anti-aging. Playing two laps: the inner ring with water with mildew; outer ring does not touch the water parts with a slightly higher bonding strength, such as general-purpose.

- Q: What are the advantages of artificial stone and quartz stone? What's the difference

- Quartz stone is the main component of quartz sand and very little resin, high hardness and high temperature does not leak oil, high quality quartz stone green light can also seamlessly stitching, because the quartz stone is too hard to do like a variety of artificial stone Shaped shape. Comparison of artificial stone and quartz stone is very simple, artificial stone is generally 11 - 12 thick, quartz stone is 15 thick, artificial stone is much lighter than quartz stone, artificial stone intolerant scraping, quartz stone scraping injury.

- Q: What kind of artificial stone is good?

- I heard that the brand is good Galanti, as if there are several major brands of cabinet countertops are used Golandi artificial stone and quartz stone, and do export.

- Q: Is the sill plate good for man-made stone or marble?

- Everything is different. Artificial stone has a seamless stitching technology, can be a large area of paving and no gap; marble is the length of the size, had to match the size, can not be seamless. Artificial stone thin, with acrylic and aluminum oxide composition, expansion coefficient, easy to deformation; marble thick, containing a small amount of radioactive elements, not easily deformed; artificial stone pattern, color and more; marble color, texture is not much, but very natural , Polished and polished better than artificial stone. Choose it yourself.

- Q: What is the density of artificial marble?

- Resin-based artificial stone Resin-based artificial stone is unsaturated polyester resin as a binder, and natural marble crushed stone, quartz sand, calcite, stone powder or other inorganic filler according to a certain proportion of cooperation, then add the catalyst, curing agent, pigments and other admixtures, Mixing and stirring, curing molding, stripping drying, surface polishing and other processes from processing. The use of unsaturated polyester products, good gloss, rich color, can be processed, decorative effect is good; this resin viscosity is low, easy to shape, at room temperature can be cured. Molding methods are vibration forming, compression molding and extrusion molding. The artificial stone used in the interior decoration works is mainly resin type.

Send your message to us

High Quality Low Carbon stone 001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 sq.m. m²

- Supply Capability:

- 400000 sq.m. Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches