Granite Tile of Artificial Stone 014

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

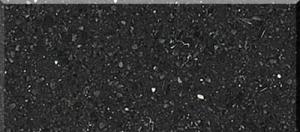

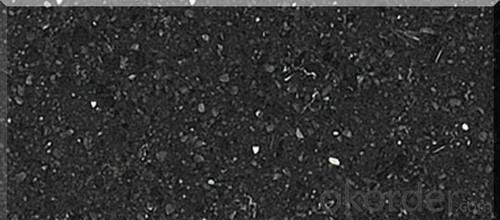

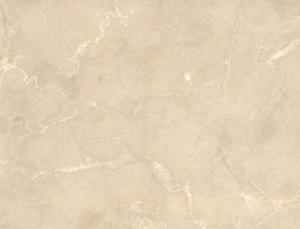

Artificial Stone 014

Cut to size for kitchen and bathroom countertops

Thickness 20-30MM

| . |

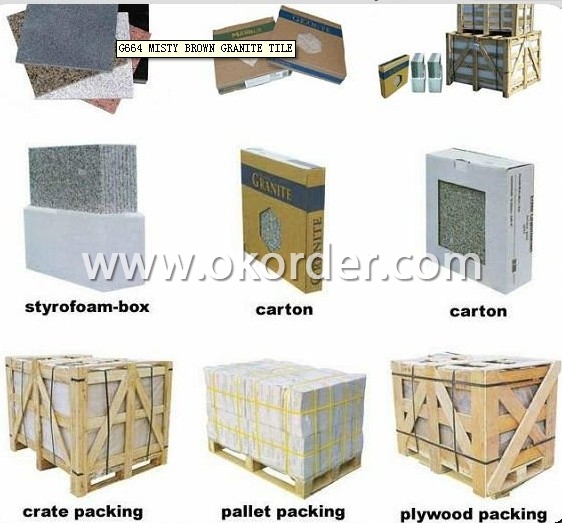

Inner: wrapped with foam Outer: wooden bundles/crates/pallet |

| Full bullnose, laminated bullnose, ogee edge, half bullnose, flat edge |

Package: | Wooden bundles/crates/pallet |

Strict monitoring management is applied in the whole processing from the raw material gathering, block choosing, manufacturing, quality testing and packaging, which can be ensured the superior quality and timely delivery.

Specifications

1. 100% Natural slate stone

2. No radiation pollution

3. Fire and freeze resistan

4. Rich in vein and Various colors

Quality Control :

We have our professional QC Team to control the quality in every link of production. The thickness tolerance is within 0.5-1mm, the polishing degree is up to 95 degree.

About the certificate

Our Advantanges:

1. We are a state-owned group company. So we have good reputation and credibility.

2. We own many qurries in china,brazil,iran,india to ensure our supply of different types of granite,marble,limestone,sandstone,etc.

3. We are a professional manufacturer so we can provide you various tiles with high quality and best price.

4. We have more than 5 years exports experience.So we can make your order more smooth.

5. All of our goods will pass THREE QUALITY INSPECTIONS before shippment.

6. Best after sale service, customer can follow their orders situation any time, no matter on production line, warehouse or shippment.

7.Special dimensions available according to your request.

8.We have many certifications of our tiles.

Here you can find good productions, better price and best service; please enjoying and welcome inquirying!

Choose us is your best choice! Our purpose is: CUSTOMER IS FIRST!

- Q: What are the characteristics of artificial stone furniture

- Features: light weight (compared with natural stone), high hardness, oil and dirt corrosion resistance. Plate thickness uniformity, good gloss, translucent effect is obvious, no deformation, fire anti-aging, no radiation, anti-penetration, according to the needs of customers free to bend, seamless bonding, really reach the natural world. In addition to artificial stone can be used to do high-grade countertops, windowsill, bathtub, basin, building columns, senior leisure table, you can also cast into a variety of sculpture ornaments, I believe there will be more use in the future will be found.

- Q: Laundry cabinet with quartz stone basin is good, or a good spinel?

- Summary: Whether it is polyline, acrylic stone or quartz stone, materials, ingredients to determine the characteristics of the work process to determine the quality, not all aspects of polycrystalline are better than other stones, nor other stone is certainly better than artificial stone, In the market, are good and bad, the user in the purchase of stone, as much as possible to compare the various manufacturers of products. Understand the use of materials, technology, workmanship, quality of service, try to sell the product manufacturers to produce test reports and sales vouchers.

- Q: Does the artificial stone do the cabinet?

- Artificial stone cabinets are no radiation, but because it is artificially manufactured, may produce some harmful substances.

- Q: For example, to what extent do not see the joints, side light or distance and the like,

- Seamless concatenation means that there is no splicing of the joints, popular terms is the naked eye can not see the two pieces of the joints in there. This is no national standard or other local standards, the general industry is about 50 cm from the surface of the board, can not find the seam even if the seamless stitching.

- Q: Quartz stone can be done as seamless as artificial stone stitching

- Not quartz stone can not be polished, you can see to do a good point of quartz stone pieces, surrounded by the surface is very smooth, is the use of high-power gas throwing machine. And if you want to do round bottom arc, the biggest may be done in the factory, but the quartz stone is not artificial stone, if it is wrong will be difficult to modify.

- Q: How to identify the quality of artificial stone?

- Poor quality calcium carbonate artificial stone will not only appear color, deformation of poor signs, due to process defects, will also cause the polymerization after the hair plate, volatile harmful gases on the human body.

- Q: Artificial stone and artificial marble for decoration

- 1, colorful, non-radioactive, safe to use; 2, and has a natural marble elegant and granite hard, with wood-like delicate and warm, with ceramic luster; stone toughness, high surface hardness, easy to damage, wear, acid, corrosion resistance, high temperature, Impact resistance and compression resistance and other functions, heat or impact is not easy to break, can be repaired very strong, can be restored to the original state of repair; 3, highly plasticity, lines rounded smooth, do a lot of modeling, the deformation of the bonding and other parts of the treatment is unique, can be seamless stitching; 4, the surface without pores, not easy to be stained, oil and water stains are not easy to penetrate them, strong anti-fouling, easy to clean; 5, easy to maintain, the surface slip marks can be used 400 mesh yarn paper water polished;

- Q: Kitchen white artificial stone dirty how to clean

- Artificial stone countertops stubborn stains clean: smooth surface with a decontamination detergent along the circular grinding, and then clean, and then dry towel dry. Use the scouring pad to wipe the entire table so that its surface remains smooth. Matte surface with a clean cloth dipped in non-abrasive cleaning agent in the circular direction of friction. Wipe dry with a towel and use non-abrasive polishes to enhance the surface effect. High gloss surfaces are sponge and non-abrasive brightener. Especially difficult to remove the dirt, can be used 1200 mesh sandpaper polished, and then use soft cloth and light agent to make it bright

- Q: My kitchen artificial stone countertops, in the house after three months of ventilation and taste, what way to clear?

- There is artificial stone powder in the kitchen Artificial stone countertops at the time of installation Produce a lot of powder these powder if the accumulation in the cabinet underground will have a taste Of course this is less likely Take a way to pick up your sleeves

- Q: Is the kitchen artificial stone countertops high temperature resistant?

- Artificial stone countertops is the advantage of beautiful, winter touched the ice hand; the disadvantage is the organizational structure of soft, easy to knock off, and seasoning easy to penetrate into the color, leaving stains, it is difficult to clear, it is recommended to use dark.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1998 |

| Annual Output Value | US$ 30 Million - US$ 100 Million |

| Main Markets | Domestic Market North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan,Nansha,Shenzhen |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 51-100 People |

| Language Spoken: | English, Chinese, Spanish |

| b) Factory Information | |

| Factory Size: | Above 35000.00 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average Hign |

Send your message to us

Granite Tile of Artificial Stone 014

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords