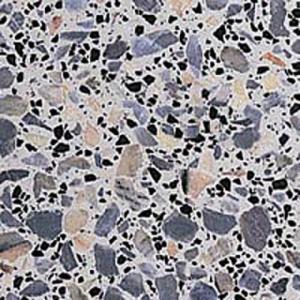

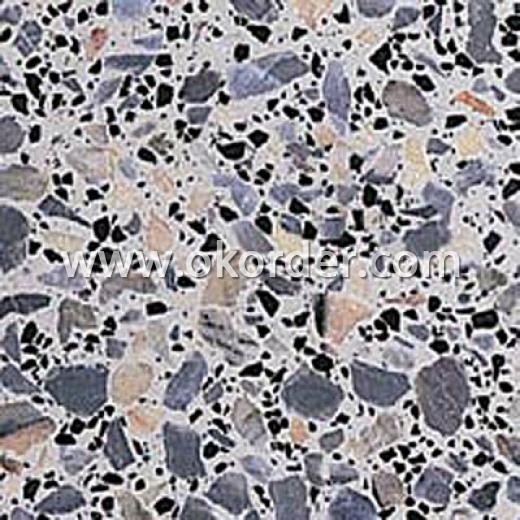

Artificial Stone 053

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information of Our Artificial Stone:

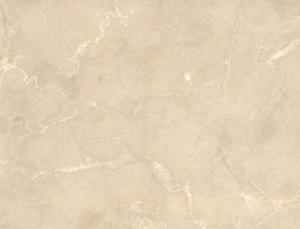

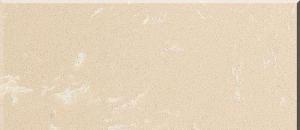

A. Quartz Surface-- 93 % pure quartz crystal, with 7 % of resins, color pigments and others

B. standard specification: 2440 mm x 760mm,3020 mm x 1420mm

C. Maximum specification: 3250mm x1650mm

D. Thickness: 12mm-30 mm

E. Passed ISO 14001 and ISO 9001:2000

F. Can offer you the highest quality products under the best price

Advantages of our artificial stone:

1,High hardness to protect from the scratching and wearing:

We pick the high hardness raw materials carefully to make sure the consistency of surface and internal quality.They have the good performance in the anti scratching and wearing, even the sharp iron tool also can not hurt it a little.

2,High temperature resistantance:

The melting point of quartz crystal is top to 1300 degree centigrade, this degree is higher than the value of daily products, so the countertap materials can bear the high temperature of scorching iron, boiling water,and boiling oil etc. and do not lead to any melt and breakage.

3,High acid-base resistance and corrosion resistance:

The quartz stone also have good performance in the resistance of acid-base.They can withstand the daily life acid and base to avoid the aging and lengthen the working life.

4,Healthy and Eco-friendly:

The natural stone have the radiation as there is heavy metal impurity existing, but the artificial quartz stone have the strict purification process to get rid of the impurity to avoid the radiation and other harmfulness. Our artificial quartz stone can directly touch the food and there is no radiation and poison.

Applications of Our Artificial Stone:

Customized kitchen top,work top,table top,counter top,vanity top,window sill,floor tile,wall tile,cut to size..

- Q: How to buy artificial stone

- Artificial stone application range is still very large, and now a lot of owners will choose artificial decoration of the kitchen as a kitchen table decoration materials, as people's demand increases, and now the market is also a lot of artificial stone types, many are Is shoddy, the demander has brought the choice of confusion. Artificial stone how to buy can observe the artificial stone style, color, color is uniform, the surface is smooth, whether it contains too much impurities. In addition, the back of the artificial stone can not have holes, or poor water resistance. Touch the stone, feel the texture. Hand touch in good quality above the stone is delicate and smooth, not rough. If there is a feeling of discomfort, it shows the quality of stone problems. Smell the smell. Pure man-made stone of good quality, no smell The poor quality of artificial stone added a lot of adhesive, smell very heavy, or even suffocating. Whether it is wearable, resistant to scratch. With a coin in the stone surface draw, good quality stone is not scratched. The same batch or the same quality of the two stone in the state of each other is not easy to break off the state. Master the above several identification skills can get rid of the choice of confusion.

- Q: How to make artificial stone countertops with double - layer composite process

- With the aforementioned preform pattern synthesis process, and then with the bulk mixture discharged in the mold box after the vacuum and pressed into a square material.

- Q: Which factory is the lowest price

- Cabinet side panels, backplane, floor, Alice or bad, edge strip off, the cabinet re-disassembly.

- Q: What is the man-made stone of the countertops?

- Acrylic stone and quartz stone is the two main types of artificial stone classification, quartz stone density is hard and hard, it is said that its hardness after the diamond, so good wear resistance, and beautiful texture, low cost. But there are shortcomings such as easy accumulation of grease, can not be formed, the gap is easy to breed bacteria and so on. In addition, man-made stone is made of non-natural mixture, such as resin, cement, glass beads, alumina powder, etc. plus gravel adhesive. Advantages are acid, high temperature, impact resistance, rich color. More important feature is easy to shape the whole.

- Q: The sill is not suitable for man-made stone, stone is not a traditional artificial stone

- Each material has its own advantages and disadvantages, slander others just because they are too stingy

- Q: Artificial stone under the basin how to use screw hook fixed

- Bonding method, but also to use flexible adhesive sealant (such as modified silane adhesive sealant, commonly known as MS glue), while bonding and sealing. After curing a certain degree of flexibility, can accommodate thermal expansion and contraction, anti-vibration, anti-aging. Playing two laps: the inner ring with water with mildew; outer ring does not touch the water parts with a slightly higher bonding strength, such as general-purpose.

- Q: My man's coffee on the artificial marble on the distribution of sour smell, how is this going on? Will it be harmful to the body?

- This is a poor man-made marble, because the use of some dye coloring, so when the high temperature exudes a smell, should have some harm to the human body.

- Q: Is it nice to use a man-made stone or a stainless steel?

- Marble stone is durable, gorgeous and beautiful, but the natural stone is not waterproof, a long time the water splash on the ground will deepen the color of the stone, into the face. In addition, marble is radioactive, to the dealer for product radioactive certificate, according to the stone's radiation level to choose; Natural marble texture hard, colorful changes, different shades, there are a variety of shiny, so the formation of a unique natural beauty. Artificial marble than natural marble light weight, high strength, thin thickness, corrosion resistance, anti-pollution, a better processing, can be made curved, curved surface, easy construction. But in the color and texture is less than natural marble beautiful, natural soft.

- Q: Artificial marble pictures are wood, and natural marble have a lot of difference?

- Natural stone advantages: pattern natural, polished feel good, hardness, compared to artificial to wear a lot, not afraid of coloring, there are pores, will penetrate the shortcomings: part of the radiation, natural stone crisp, flatness difference broken Stone and marble connection is very obvious, can not be seamless splicing, easy to breed bacteria, lack of flexibility, difficult to repair, the rapid changes in temperature will be broken.

- Q: Artificial jade (artificial marble) above the tea traces how to clear?

- Special care 1) some stubborn stains decontamination steps, according to the degree of polishing performance of the plate depends on: decontamination detergent cleaning circle, and then clean, and then dry with a towel, then use the scouring pad to wipe the entire table again, so that Keep the surface smooth. 2) semi-matte surface: with a scouring cloth dipped in non-abrasive cleaning agent circle grinding, and then dry with a towel, and non-abrasive polishing material to enhance the surface bright effect. The Precautions for use 1) have sharp edges and corners of things to gently, to prevent scratching the surface of the table. 2) try to keep the table dry, to avoid the formation of stubborn stains. For example: soy sauce, oil and tea and so on. 3) can not use the steel wire to wipe the surface directly, but can not use the knife scraper surface. 4) can not be carried out on the artificial stone countertops. Such as pedals, heavy pressure, severe vibrations and heavy objects falling on its surface.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | US$ 6 Million - US$ 20 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11 - 20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Artificial Stone 053

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000SQM m²

- Supply Capability:

- 3000SQM/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords