High Quality Automotive Car Painting Heat Resistant Masking Tapes Packaging Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General purpose of Automotive Car Painting Heat Resistant Masking Tapes

1) good adhesive

2) good flexibility

3) No residual left

4) Different sizes are available

Feature of Automotive Car Painting Heat Resistant Masking Tapes

general purpose masking tape, adhesive tape, paper tape.

1) good adhesion. 2) good flexibility.

-General purpose masking tape is made of crepe paper coated with natural rubber adhesives.

-It is designed for interior paint masking, light-duty packaging, holding, bundling, splicing and packaging.

-Practical for construction, building, home, office or industrial applications.

-Jumbo roll, log roll and cut roll are available.

-The width of jumbo roll is from 980mm - 1250mm

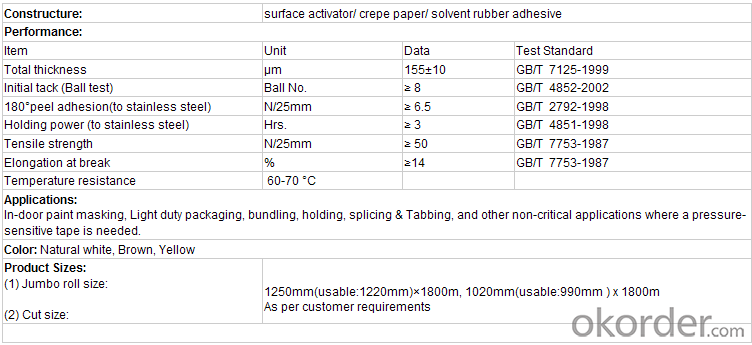

Specifications of Automotive Car Painting Heat Resistant Masking Tapes

Advantages of Automotive Car Painting Heat Resistant Masking Tapes

Different temperature resistance with good adhesion

High tensile strength, good resistance of damage, no residue, eco-friendly

Accept custom design

SGS, ISO, BV, CTI certificates approved

Professional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive tapes

Special size, color can be made according to customer's requirement.

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

FAQ

Q 1: Do you have any MOQ of Wonder Masking Tape?

A: Yes, according to the size you need.

Q 2: What is the delivery time?

A: Sample time 7 days, 30 days for the mass production.

Q 3: Can we put our logo on the products?

A: Yes, welcome.

Q 4: How should I pay for you if I place order to you?

A: Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: How to adjust the tightness of belt pulley in belt sealing machine?

- Full automatic sealing machine, pneumatic sealing machine, folding lid sealing machine, corner sealing machine,

- Q: Are there any specific instructions for reusing packaging tape?

- Yes, there are a few specific instructions for reusing packaging tape. Firstly, ensure that the tape is still in good condition and is not torn or damaged. Gently peel off the tape from the package, being careful not to rip it. Next, find a clean surface to roll the tape onto, such as a smooth piece of cardboard or a tape dispenser. Avoid folding or crumpling the tape as it may lose its adhesive properties. Finally, when reusing the tape, make sure to press it firmly onto the new package to ensure proper adhesion.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape typically exhibits resistance against a broad array of chemicals. Commonly, packaging tapes are crafted from materials like polypropylene or polyvinyl chloride (PVC), renowned for their chemical-resistant properties. These materials possess the capacity to endure exposure to different chemicals, including solvents, acids, and bases. Nevertheless, it is crucial to acknowledge that the degree of chemical resistance can vary depending on the specific type and quality of the packaging tape utilized. Certain tapes may display higher chemical resistance compared to others. Furthermore, the tape's resistance can be influenced by the duration and intensity of chemical exposure. To guarantee the tape's chemical resistance, it is advisable to review the manufacturer's specifications and guidelines concerning chemical compatibility. If you are handling exceedingly harsh chemicals or engaging in specialized applications, it may be necessary to seek out packaging tapes explicitly designed for those specific conditions.

- Q: How do I prevent packaging tape from losing its color over time?

- Here are a few strategies you can try to prevent packaging tape from losing its color over time: 1. Properly store the tape: To maintain its color for longer, keep your packaging tape in a cool, dark, and dry place, away from sunlight and extreme temperatures. 2. Avoid moisture: Moisture can damage the adhesive and color of the tape, so store it away from areas prone to water leaks or high humidity levels. 3. Opt for high-quality tape: Look for packaging tapes made with better quality materials that are designed to retain color for a longer period. 4. Minimize exposure to air: After use, seal the packaging tape tightly to reduce its exposure to oxygen, which can contribute to color degradation. 5. Handle with care: Rough handling can cause the color to rub off or fade faster, so be gentle when applying and removing the tape. 6. Consider protective coatings: If the packaging tape is important for branding or aesthetic purposes, you can explore using protective coatings or laminates to add an extra layer of protection against color loss. By implementing these measures, you can extend the lifespan and vibrancy of your packaging tape, ensuring it remains visually appealing for a longer period of time.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Yes, packaging tape can be used for sealing packages with fragile artwork or sculptures. However, it is important to choose the right type of packaging tape to ensure the protection of the artwork. Generally, it is recommended to use a high-quality, heavy-duty packaging tape that is specifically designed for shipping and handling delicate or fragile items. These tapes are often reinforced with fibers or have extra adhesive strength to provide a secure seal and prevent damage during transportation. Additionally, it is advisable to use proper cushioning materials such as bubble wrap or foam padding to protect the artwork inside the package.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. Packaging tape is designed to have a strong adhesive that adheres well to various surfaces, including foam and bubble wrap. By applying packaging tape to the edges or seams of foam or bubble wrap, you can securely seal and protect your items during shipping or storage. It is important to ensure that the tape is applied properly and firmly to provide a tight seal and prevent the foam or bubble wrap from coming loose.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Indeed, bubble wrap can be effectively sealed with packaging tape. The purpose of packaging tape is to establish a robust and secure seal on diverse materials, bubble wrap included. In the packaging and shipping sectors, it is widely employed to guarantee the safety and security of package contents throughout transportation. To ensure optimal protection and prevent any potential harm or exposure, it is essential to apply the tape along the edges of the bubble wrap, creating a snug seal.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, there are several steps you can take: 1. Choose the right type of packaging tape: Make sure you are using a high-quality packaging tape that is designed for heavy-duty applications. Look for tapes that are specifically labeled as tear-resistant or reinforced. 2. Prepare the surface: Before applying the tape, ensure that the surface is clean, dry, and free from dust or debris. A dirty or uneven surface can cause the tape to tear easily. 3. Use proper technique: When applying the tape, hold the roll at a slight angle to the surface rather than perpendicular. Applying it at an angle will reduce the amount of friction between the tape and the surface, minimizing the chances of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, using gentle pressure. Avoid pulling or tugging too hard, as it can strain the tape and increase the risk of tearing. 5. Avoid extreme temperatures: Extreme temperatures can affect the adhesive properties of the tape and make it more prone to tearing. If possible, store the tape in a controlled environment and avoid using it in extremely hot or cold conditions. 6. Consider using a tape dispenser: Using a tape dispenser can help you apply the tape more smoothly and evenly, reducing the chances of tearing. It also provides better control and minimizes the strain on the tape. 7. Cut the tape cleanly: When cutting the tape, use a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make it more likely to tear. By following these tips, you can significantly reduce the chances of packaging tape tearing during application and ensure a secure and reliable seal for your packages.

- Q: Can packaging tape be used for sealing plastic storage bags?

- Yes, packaging tape can be used for sealing plastic storage bags. It provides a strong adhesive bond that helps keep the bags securely sealed.

Send your message to us

High Quality Automotive Car Painting Heat Resistant Masking Tapes Packaging Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords