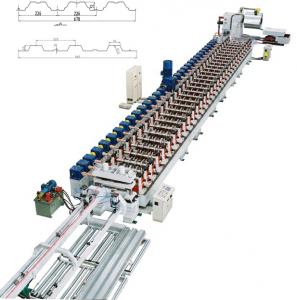

High quality 8MF profile production equipment

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

of the machine is beautiful because we adopt the shape-steel structure and process as a whole after welding. It has the ability of strong loading and stable operation when running the machine.

All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

It is very easy to install the equipment and suitable for producing in the factory.

T

he machine has features of low noise and high efficiency.

1- Explanation

C-Z quick interchangeable machine adopts a special structure. The rollers for C & Z are changed very quickly without dismantle any parts. One machine can produce all specifications of C & Z purlins. Crimples are optional to increase rigidity of purlin. And the PLC can control adjust the any size in automatic and all of parts of machine adopt high configure.

Item | Description | Qty |

1 | Hydraulic de-coiler with hydraulic car in 10 tons weight capacity | 1 unit |

2 | Pre-cutting machine | 1 unit |

3 | Straightening and guide system | 1 unit |

4 | Feeder system | 1 unit |

5 | Hydraulic punching system | 3 unit |

6 | Punching moulds | 6 sets |

7 | Roll forming main machine | 1 unit |

8 | Hydraulic shape-cutting | 1 unit |

9 | Automatic stacker | 1unit |

10 | Control panel with electrical cabinet | 1 unit |

11 | Hydraulic power supply | 1 unit |

2- Line configuration

3- Main machine specifications

Main dimension: | 11000 x XXXX x 1800mm (L x W x H) |

Total weight | 14000kg |

Main motor | 22KW Chinese GUOMAO |

Feeding, leveling motor power | 5.5KW |

Hydraulic pressure | 15-25MPa |

Hydraulic power | 7.5KW |

Steps of rollers | Feeding & guiding: two sets |

Leveling: one set, seven rollers | |

Main forming: 20 steps | |

Rectifying: one step | |

Forming speed | 18 m/min (not include the punching and cutting time) |

Adjust the size | by PLC |

Purlin specifications for 8 MF | width: 100-350mm |

height: 40-100mm | |

thickness: 2-4mm |

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- 2 check the main parts of the machine fasteners are loose phenomenon;

- Q: How to maintain the molding machine?

- 1 Check the host before driving is complete, than with loose and electrical loose, electrical grounding is good.

Send your message to us

High quality 8MF profile production equipment

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches