High Purity Aluminum Oxide Raw Materials for Refractory Alumina Oxide Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Purity Aluminum Oxide/ Aluminium Oxide/Alumina Oxide Al2O3

Specification:

1. High Purity Alumina Powder manufacturer

2. 99.995% purity

3. Four types: powder,ball,pellet and crystal

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

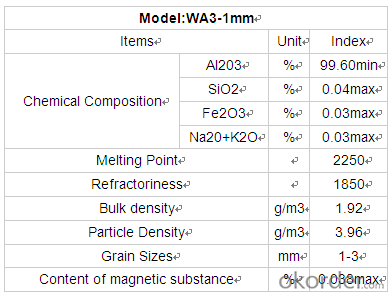

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q: About the market issues of thermal insulation material and refractory material.

- In fact, the thermal insulation material produced by the Sichuan-Benniao Hing construction company is very good, you can get the company's information just by inputing the Sichuan-Benniao Hing construction company into Baidu

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- the fire resistant level of aerated concrete building blocks can reach the grade one level. Aerated concrete strength grade shall be divided according to the concrete cubic compressive strength value. Use the symbol C and the cube compressive strength value (in N / mm2 or MPa gauge) to express. According to GB50010-2002 "concrete structure design specifications" provisions, ordinary concrete is divided into fourteen levels, namely: C15, C20, C25, C30, C35, C40, C45, C50, C55, C60, C65, C70, C75, C80 .

- Q: What are the structural properties of refractory materials provided by the manufacturer of the refractories include?

- On the other hand, the turbulence is severe, and the side wall of the tundish is washed into the liquid steel and the service life of the lining of the tundish is reduced. In order to solve this problem, China 5%% honing develops a tundish anti turbulence pad, which is made of Al2O3>75% high alumina castable. Anti turbulence pad mounted casting ladle and tundish flow impact zone in the bottom of the flow out of the steel ladle nozzle casting hole center back in the anti turbulence pad repeatedly to consume the kinetic energy of the fluid flow, thereby reducing the steel flow speed, avoiding turbulence.

- Q: Which refractory quality inspection authority is good?

- Download refractory quality inspection LIRR in Henan is nationally recognized. Of course, it is an authority, but the cost is very high.

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: What is high alumina refractory?

- It refers to inorganic non-metallic material with refractoriness of higher than 1580℃. Refractoriness refers to the celsius temperature that the cone-shaped refractory sample without load can resist, and under which the sample won't soften and melt down. Refractory material appears together with high temperature technology, and roughly dates from the Middle Bronze age. In the Eastern Han Dynasty (AD25~AD220) of China, fireclay refractories has been used as furnace refractories and saggers for making porcelains. In the early 20th century, refractory material develops toward the direction of high purity, high dense and ultra high temperature products, and meanwhile unshaped refractory and refractory fiber with no need of firing at all and with low energy consumption appear.

- Q: Fire resistance and evaluation of refractory for casting

- The refractory degree of refractory material at high temperature is called refractoriness. Refractory products all contain substances from fusible sintering action, the melt crystal as unlike at a fixed temperature, but the temperature in a wide range. At a lower temperature, a small amount of melt is formed, and as the temperature increases, the amount of the melt increases, and the product gradually softens. Refractoriness and melting point (crystal) are different concepts.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: What is refractory cement?

- Ordinary portland cement is common cement with relatively high early strength, while refractory cement is low in this regard. Refractory cement is a characteristic cement which can only be used in special projects, not suitable for general engineering. And in the winter, it is not suitable for construction use.

- Q: Do you know where I can buy refractories?

- Refractories are sold in following companies : Address of Huadu Refractories Co., Ltd. : NO.11 Huanjin Road, Fuyang, Hangzhou Address of Zhenxing Special Fire-Proof Material Co., Ltd. : No. 54 Pingjing Road, Yuhang District, Hangzhou Address of Zhongnai Refractories Co., Ltd.: No. 345 Fuyang, Hangzhou, Zhejiang Province

Send your message to us

High Purity Aluminum Oxide Raw Materials for Refractory Alumina Oxide Al2O3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords