High Purity Alumina Ceramic Fiber Paper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper

l Okorder ceramic fiber paper is manufactured with high purity refractory fiber. The advanced technology makes the distribution of fiber very even.

l Okorder ceramic fiber paper is made with minimum bond. The ceramic fiber paper will be completely burnt during the usage.

l Ceramic Fiber Paper has great flexibility, mechanical performance, and excellent refractory and high temperature insulating performance.

Feature of Ceramic Fiber Paper

Withstand high temperature

Low thermal conductivity

Less heat storage

Resistance to thermal shock

Stabilized to most chemical

Corrosion resistance

Not easily torn

Absorb sound

Even density and thickness

Easy to install

Application of Ceramic Fiber Paper

High temperature gasket

Boiler door seal

Refractory expansion joint

Furnace backup insulation

Lining for aluminum casting molds

Thermal and electrical insulation for heaters

Acoustic and thermal insulation for automobile mufflers

Heat insulation for exhaust tubes and pipes

Electrical switch box fire protection

Image of Ceramic Fiber Paper

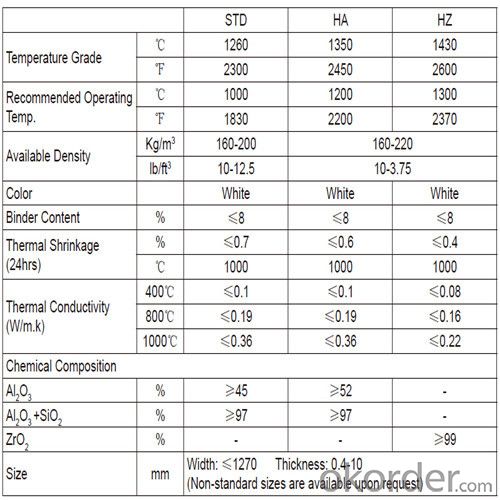

Technical Data of Ceramic Fiber Paper

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: How are ceramic fiber papers attached to the interior wall?

- Ceramic fiber paper afraid of water, and no adhesion, putty powder is difficult to hang, it is almost impossible to wallpaper, ceramic fiber paper with ceramic fiber mortar by vacuum filtration process, the surface will remain part of the fiber powder, suggest that you make ceramic fiber paper on the walls of the inner layer. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter.

- Q: Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- The advanced production technology enables the fiber to distribute very evenly, and the paper thickness and bulk density can also be strictly controlled. Ceramic fibers have very low thermal conductivity. The thermal conductivity of ceramic fiber paper was measured by thermal flow method.

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- However, insulating bricks and refractory fibers can not be abused at will. So far as the basic oxygen furnace, cement rotary kiln lining, due to the high temperature chemical erosion, temporarily cannot be used for lining fiber. Ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment such as ceramic tunnel kiln, has already achieved by ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment lining, according to relevant reports, quickly push board kiln and tunnel kiln in the energy saving effect of fire resistant ceramic fibers are very significant. In particular, ultra high temperature heating, such as burning temperature in 1538 to 1649 degrees of furnace, the use of refractory fiber energy saving effect is best. Ceramic fiber products (aluminum silicate fiber products) at present, Europe and the United States and Japan all ceramic kiln equipment using ceramic fiber products (aluminum silicate fiber products) lining. Not long ago, Japan will be decomposed into compartments such as gas tunnel kiln structure, and then to the segmented manufacturing factory construction site assembly, all of this is due to the use of ceramic fiber material, greatly saves the cost of more convenient because of the kiln. The research on energy saving effect of ceramic fiber products is also being carried out from the aspects of material modification. Ceramic fiber products (aluminium silicate fiber products)

- Q: What can I do to get the clothes off the ceramic fiber?

- Remove pen marks from clothes easilyFirst of all, the alcohol evenly sprinkled on the pen printed on the pen, alcohol should be used at a concentration of not less than 75% of the alcohol used in medicine. Remember to put on this side of the garment that has been poured down. Do not touch other surfaces of the garment. Otherwise, the color of the pen may be stained with other parts of the garment.Prepare most of the water, and then pour two full bottle of bleach water in the water, stirring, and a little washing powder, so that the laundry powder can be fully dissolved in water. Soak your clothes completely in water for twenty minutes. Washing clothes, there is no mark!Clothes stained with pens, ball pen marks, there is another way to solve: that is, do not rush to the clothes into the water, but first wash with gasoline, washed parts of the re wash.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q: What are the features of ceramic fiber gaskets?

- Mifso-11 ceramic fiber gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- Aluminum alloy advantages: air oxidation resistance, cost-effective, easy to manufacture. The disadvantage is that the elasticity is poor and the strength is low.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket?

- Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining.

Send your message to us

High Purity Alumina Ceramic Fiber Paper

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords