High Pressure Rubber Air Hose High Temperature for Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

Structure

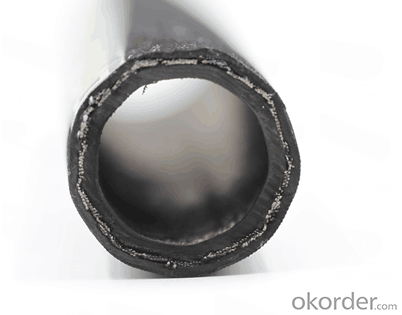

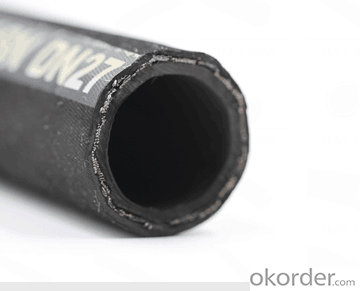

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: How can the rubber pipe leaking from the cold water inlet of the electric water heater do?

- Estimation is inside the pipe aging cracking due to Water Leakage, no maintenance necessary, unless it is a joint sealing ring in aging can replace the sealing ring of new or with rubber or other flexible items I cut a replacement.

- Q: What are the production processes and characteristics of high pressure rubber hose?

- Production flow chart of high pressure steel wire braided hose:High voltage wire winding production process: rubber hose, pipe extrusion, boiled casing (core wipe silicone oil), wrapped around the screen (screen on the casing after finishing cutting winding), a layer of glue, the first layer of steel wire winding, two winding layer of glue, second layers of wire, third in the layer of glue, third layers of wire winding layer, fourth layer, fourth layer winding wire, package cover, water roll of cloth, cloth, water solution of vulcanization, mandrel stripping, a hydraulic, appearance and dimension inspection and packaging storage.

- Q: Can the high-pressure rubber hose be followed by water pipes? Will it be poisonous?

- No, because I did not meet the drinking water level requirement!! Hose with drinking water hose!! Drinking for a long time is poisonous!

- Q: How do you remove the burrs on the rubber joint quickly?

- Frozen deburring machine is a kind of ultra low temperature using liquid nitrogen to make rubber, plastic products, zinc alloy burr occurs rapidly embrittlement, and under this condition, the burr of high-speed jet impinging particles of frozen products, so as to achieve both high quality and high efficiency removal products of burr, and keep possession the product itself does not change. The utility model can greatly improve the deburring precision of products, and has a high degree of intensification.

- Q: What is the rubber sleeve flange connection sleeve?

- Rubber flexible joint flange connection sleeve flange gate valve quota.

- Q: Can high speed air flow through a rubber tube and produce static electricity?

- As a result of friction, high velocity flow of gas through the rubber pipes will produce static electricity.

- Q: What material is the rubber joint used in the desulfurization pipeline? What's the difference?

- If you choose the ordinary material or other special materials, it will inevitably be broken. Because of the different materials of rubber joints, the application environment is different.

- Q: What are the rubber pipe joints perfectly joined to the pipe fittings?

- Rubber tube joints are flanged in general. Thread.

- Q: What are the types of metal hose couplings?

- DGJ jointStructure and characteristics:DGJ self fixing metal hose joint, it can connect non threaded steel pipe or screw free equipment outlet and hose, and save the thread setting process;The metal joint is made of zinc alloy. The surface is zinc plated, sanded or chrome plated. The structure is compact and the strength is high. The steel pipe and the metal hose are connected reliably, and the appearance is beautiful;The metal joint is self - fixing and is used to connect the metal hose to the non - threaded steel pipe or the screw - free equipment outlet;Suitable metal hose: JS, JSH, JSB, JSHG;Adaptation: steel thin steel wire pipe, black, tin pipe (water, gas);When choosing the DGJ self fixing metal hose joint, please pay attention to the specification and size of the connecting pipe hose.

- Q: What with the appropriate suction tube Dichotomanthes tube and rubber machine

- The bellows are extruded by the extruder, and the winding tubes are wound in circles

Send your message to us

High Pressure Rubber Air Hose High Temperature for Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords