High Pressure Rubber Air Hose High Temperature Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

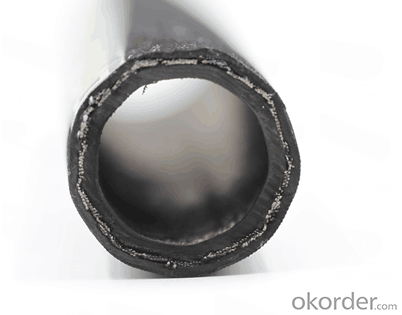

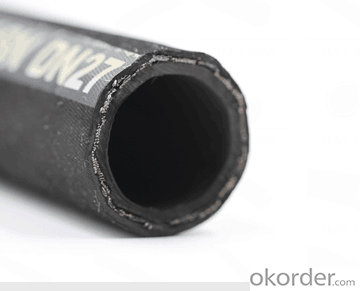

Structure

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: How can I connect the gas tank connection hose?

- The general is directly inserted into the connector on the line, if loose, can use wire twist, still feel not reliable, can go to the market to buy two hoop, screw on the line.

- Q: What is the essential difference between rubber expansion joint and rubber joint?

- Rubber joint is a kind of pipe joint with high elasticity, high air tightness, medium resistance and weather resistance. The product uses rubber elasticity, high air tightness, medium resistance, weather resistance and radiation resistance etc., using polyester cord fabric skew high strength, strong stability and the hot and cold composite, after high pressure, mold temperature and curing. As the rubber joint has good comprehensive performance, it mainly acts as shock absorption, noise elimination and noise reduction. Therefore, it is widely used in chemical, construction, water supply, drainage, petroleum, light and heavy industries, freezing, sanitation, plumbing, fire fighting, power and other infrastructure projects.

- Q: How can we prevent the aging of rubber tubes?

- The second is the design of the structure of the rubber products (especially damping products), has a great relationship between aging and fatigue, should avoid stress concentration! If the product is good has been produced to prevent aging, more trouble! Can be sprayed on the rubber surface, spraying insulation polymer.

- Q: Will the outside of the brake hose of the car burst apart?

- If the brake oil pipe (you should be the brake hose) is best, I'd recommend replacing him

- Q: Why should liquefied petroleum gas use strong rubber hose and liner?

- In order to remind people of the leakage of liquefied petroleum gas in a timely manner, the processing plant often mixes a small amount of foul odor mercaptan or thioether compounds into liquefied petroleum gas, which is the source of special odor.

- Q: Hose connector JB1885-77 what is the standard?

- The pipe joint oil sheet, wool, steel board, combined sealing washer or sealant leak, whatever the material, should first check the seal is damaged, and rough conditions such as deformation, aging, and then take corresponding measures.

- Q: Toilet hose and water tank joints leaking, how to repair?

- Remove the joint, wrap the tape, and press again

- Q: The use of anti slip rubber joints under what circumstances?

- The flange connecting the rubber joint shall be the valve flange or the flange conforming to GB/T9115.1 (RF).

- Q: How can the hose of natural gas be connected to the water heater?

- It should be noted that when the nut is installed, pay attention to each nut must have plastic or rubber soft gasket, gasket must be flat, it plays the sealing role of the joint of the pipe joint.

- Q: How can the rubber tube be used properly and how to use it properly?

- Due to the aging hose burst of high temperature oil. Operation engineering machinery, hydraulic system for power loss and oil heating, and the influence of the outside temperature (especially in summer), the sharp increase in oil. The oil using high temperature, banana aging, elastic variation, decline the strength and sealing performance, the hose will soon burst. Therefore, during the operation, when the hydraulic system temperature is too high, too fast, should identify the reasons, be excluded; summer homework, especially in continuous operation, should take necessary measures to cool down.

Send your message to us

High Pressure Rubber Air Hose High Temperature Steel Layer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords