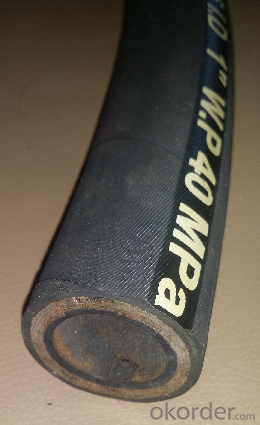

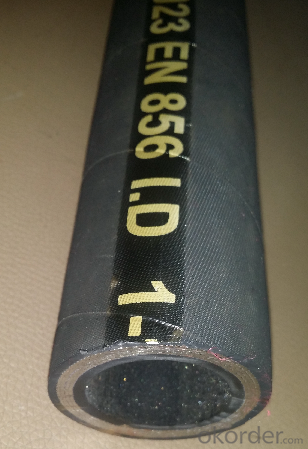

High Pressure Rubber Fuel Hose High Temperature

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

Structure

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: Plastic coated metal hose flexible conduit joint what treatment

- You see what the other end is connected to the main, if the connecting hose can be used self fixed joints, if no thread connection pipe, to set joint by three column card, if the connection device or threaded pipe, external thread joint, and some fittings, Glenn joint

- Q: Can the spring hose joint be connected to the tap?

- Two treatment1 if Water Leakage can choose to replace the elbow elbow, the best selection of true Shide profiles or fittings2 if the ground is Water Leakage, nine in ten was a cause of the pipe in the ground before the hot melt glue of the elbow. Then have to ask the property or a professional plumber to weld.

- Q: How to prevent leakage of rubber joint check valve?

- Through the internal and external pressure difference to achieve, without any power or manpower, and therefore to prevent backward flow is the best choice.

- Q: How can I keep the rubber tube for stethoscope?

- I don't think this question should be considered purely from the point of view of sound transmission.

- Q: How can we prevent the aging of rubber tubes?

- Formula design is the most important. Rubber formula design is directly related to the service life of the product!

- Q: Standard for implementation of type KXT-1 rubber joints

- This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems. Rubber joint manufacturing standard CB-T 965-95 CJT208-2005 to take over the compensation rubber flexible rubber joint CJT 3013.1-1993 KST flexible rubber joint

- Q: Is the metal hose the same as the soft connection?

- One hundred and eight thousand in the metal hose and PVC casing, installation of on-line outside for protection, metal hose used in the instrument signal line, the soft connection is on the main circuit element used to protect the main loop stiffness damage loop, such as motor and pump connected with a soft connection,

- Q: Hose connector JB1885-77 what is the standard?

- The reason of high pressure hose joint leakage are the following: "a" ring aging or deformation caused by leakage; the "C" ring assembly is not in place, the two plane connection or "C" uneven pressure ring is cut caused by leakage; "a" ring without compaction, the elastic deformation caused by leakage; the "C" ring spigot groove deep caused leakage. In this regard, the need to re select the same diameter and thick section "C" ring, can also be provided with a sealing plane rabbet groove of cutting or grinding, in order to reduce the rabbet groove depth, the "C" ring has enough elastic deformation (compression should be between 0.35-0.65mm).

- Q: Production process and raw material of rubber

- The relationship between tensile strength and rubber structure: a large force between molecules, such as polar and rigid groups; the molecular weight increases, increasing the fan Edward force, the chain segment is not easy to slip, the equivalent of molecules formed between physical crosslinking points with the molecular weight increased, the tensile strength increased to a certain extent reached equilibrium; microstructure the molecular structure, such as the effect of cis - and trans structure;

- Q: Faucet hose connection problem

- Ball valves can be made, but easy to leak. More than a few times to install a feeling, when the screw does not use brute force ah.

Send your message to us

High Pressure Rubber Fuel Hose High Temperature

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords