High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Process Line of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

RAW MATERIALS → CUTTING → STOVE → FORGING → TRANSFER MACHINE → QUENCHING → HEAT TREATMENT → DIMENSION TESE →PACKING →TRANSPORTATION OR SEA FREIGHT

Chemical Elements of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

C | Si | Mn | Cr | S | P |

0.50-0.65 | 0.15-0.37 | 0.6-1.2 | ≤0.25 | ≤0.04 | ≤0.04 |

0.7-0.9 | 0.45-0.75 | 0.7-1.25 | 0.11-0.4 | ≤0.04 | ≤0.04 |

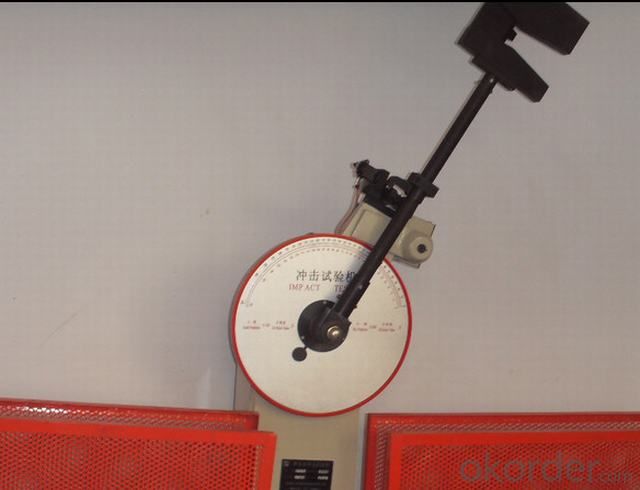

Specification and Hardness of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

Nominal diameter (mm) | Diameteical tolerance (mm) | Weight of signal forging Ball in average (g) | Number of piece of one ton forging ball in average | Surface hardness (HRC) | Impact toughness (j/cm²)) |

φ20 φ25 φ30 φ40 φ50 | +2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1946 |

50-65 |

≥12 |

φ60 φ70 φ80 φ90 φ100 | +3 -2 | 888 1410 2104 2996 4110 | 1126 709 475 333 243 | ||

φ110 φ120 φ130 | +4 -2 | 5457 7102 9030 | 182 140 110 |

45-60 | |

φ140 φ150 | +4 -3 | 11278 13871 | 88 72 |

Application fields of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

1).Metal mines 2).Cement plants 3).Power station 4).Chemical industry

5).Chemical engineering

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: Is 316 casting better than 304 casting?

- It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

1. Manufacturer Overview

| Location | Jiangyin City, Jiangsu Province, China |

| Year Established | 2012 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South America; Oceania; Eastern Europe; Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish; Portuguese; Russian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords