Ceramic Fiber Board with High Compression Strength Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 kg

- Supply Capability:

- 9000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

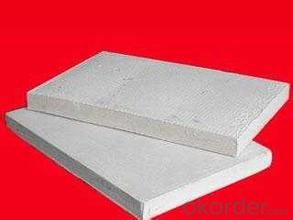

Ceramic fiber board is a wet vacuum filter pressure forming, plus the use of loose cotton made ??of organic and inorganic binders. The product has a hard texture and excellent strength, resistance to erosion, cut and easy processing. The fire-resistant fiber materials chemical stability, and thus light weight, thermal insulation effect is good, is a versatile product that can be used in lining hot flame and heat resistant surface air direct impact.

Features:

Low thermal conductivity, thermal shock, high temperature stable performance, good sound insulation, a wide range of bulk density (300-600 kg/m3), product variety, temperature dependent (800oC-1800oC), corrosion resistance, easy processing cutting, direct contact with flame, easy to install.

Application:

First,the furnace door

Second,the equipment heating insulation and electrical insulation materials

Third,glass and enamel

Fourth,high-temperature insulation

Fifth,a variety of high-temperature furnace lining ladle permanent layer,tunnel kiln,roller k

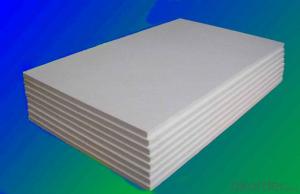

Have been using the latest high-tech, industrial results B-1800 ultra-high temperature refractory fiber market, the product has a high temperature, short-term use up to 1800oC, continuous use temperatures up to 1750oC, and the product has a resistance to thermal shock good performance, versatile and so on.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: What are the sound-absorbing fiber boards?

- Sound-absorbing material:1, itself has sound-absorbing properties, porous fiber material.2, does not have sound-absorbing material, but processed into sound absorption structure.Common sound-absorbing materials are: polyester fiber sound-absorbing board, trough wood sound absorption board, hole wood sound-absorbing board, recycled wood sound-absorbing board, the latest is Dr. sound, high temperature ceramic sound-absorbing board, a fire prevention, water quality, hard environmental protection

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Ceramic fiber board is a kind of ceramic fiber cotton produced by injection technology. It is made by continuous production and advanced technological production line.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

Send your message to us

Ceramic Fiber Board with High Compression Strength Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 kg

- Supply Capability:

- 9000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords