Ceramic Fiber Board Insulation Roll for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fibre Insulation Roll Used As Furnace Lining

Structure of Ceramic Fibre Insulation Roll Description

Ceramic Fibre is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic Fibre Insulation Roll has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of Ceramic Fibre Insulation Roll also has difference,and they are suitable for different workong temperatures.

Ceramic Fibre can be used after optional cutting .When Ceramic Fibre Insulation Roll storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

We are the main supplier for

Allied mineral products, inc

Refractories incorporated

Srs sorg refractory systems gmbh,

Sunward refractories co., ltd

Lilama69-1 joint stock company etc.

Main Features of the Ceramic Fibre Insulation Roll

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fibre Insulation Roll

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

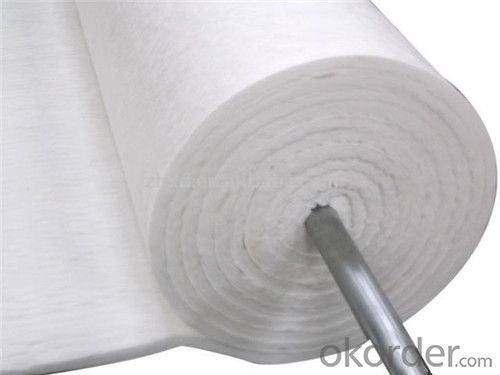

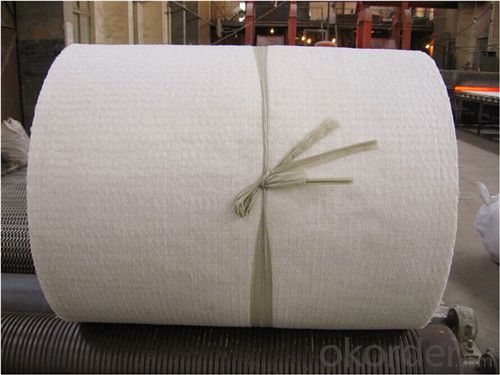

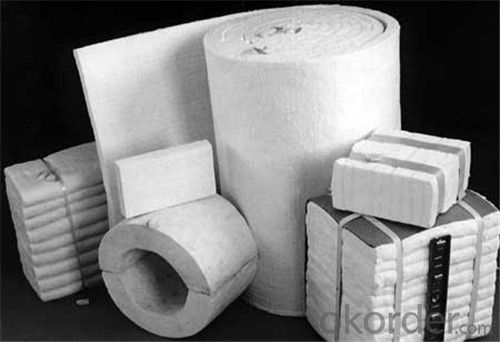

Ceramic Fibre Insulation Roll Images

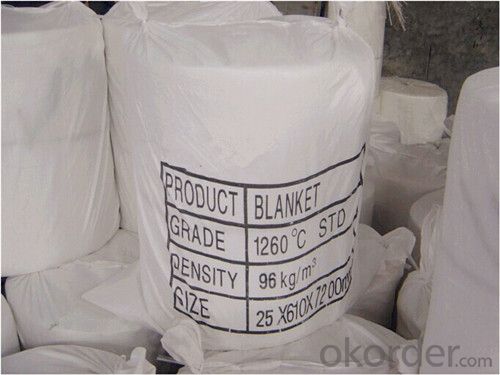

◆Packaging

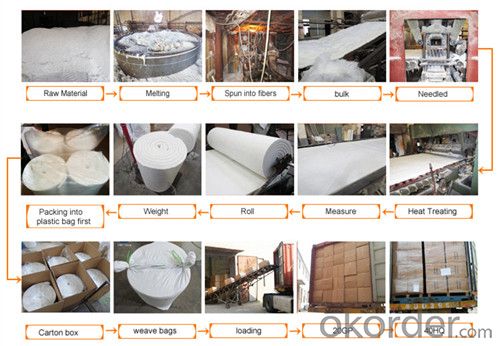

◆Product Process

Ceramic Fibre Insulation Roll Specification

Type | Ordinary | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

Density (kg/m3) | 96 | 96 | 96 | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

FAQ of Ceramic Fibre Insulation Roll

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can you accept OEM for Ceramic Fibre Insulation Roll?

A:YES! We can according your demand to produce.

Q10:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Ceramic fiber board is a kind of ceramic fiber cotton produced by injection technology. It is made by continuous production and advanced technological production line.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

Send your message to us

Ceramic Fiber Board Insulation Roll for Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords