High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

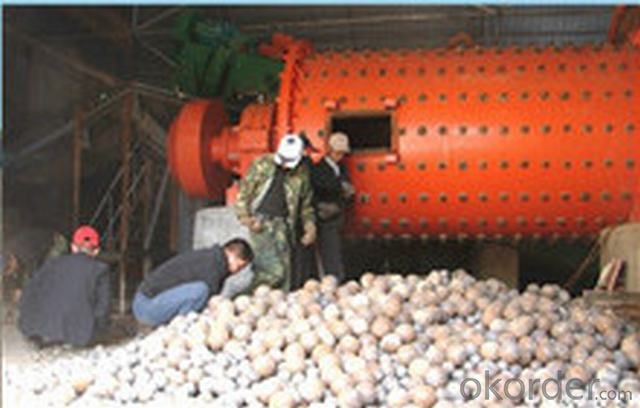

Feature of High Chrome Casting Grinding Ball For Cement Plant Sute By ISO 9001

1) In general, casting steel ball has high hardness: surface hardness to 56 HRC, volume hardness of 45-56 HRC

2) impact toughness high: impact toughness more than 4 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 1%.

4) loss of grinding casting steel ball round rate is low.

Chemical composition of High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

Based on material, the forged steel balls are defined into 7 brands. And The chemical composition is shown in the following:

Brand | Material | C | Mn | Si | Cr | S | P | V |

Special-1 | 50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

Special-2 | 60MN | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

Special-3 | 65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

Special-4 | 75Mn | 0.72-0.92 | 0.17-0.37 | 0.17-0.37 | 0.4-0.6 | ≤0.035 | ≤0.035 | |

Special-5 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

Special-6 | 75SiMn | 0.70-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

Special-7 | Wear-resistant Alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

Main Process of High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

(1).Raw material (2).Cutting (3).Heating (4).Forging (5).Quenching

(6).Tempering (7).Testing (8).Qualified Products (9).Packing

Production system of High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

mold design, chemical analysis, forging, mechanism processing, and quality inspection.

Quality Control of High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

1.Chemical Composition confirm after Ingot

2.Hardness after Heat Treatment

3.Final Dimension Check

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting.

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

1. Manufacturer Overview

| Location | Jiangyin City, Jiangsu Province, China |

| Year Established | 2012 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South America; Oceania; Eastern Europe; Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish; Portuguese; Russian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

High Chrome Casting Grinding Ball For Cement Plant Suet By ISO 9001

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords