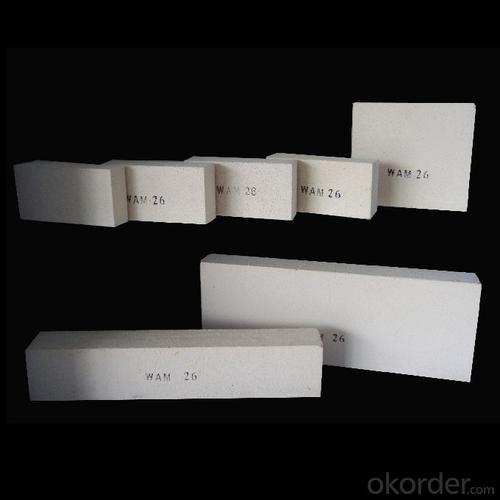

High Alumina Brick for Foundry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High Alumina Refractory Brick for foundry are high performance refratory products manufactured with unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity and compressive strength.

Advantages of High Alumina Refractory Brick:

High refractoriness.

Good spalling resistance and wear resistance.

Good corrosion resistance.

Good thermal shock resistance.

Applications:

High Alumina Refractory Brick is highly applied in below:

Steel furnaces

Iron making furnaces

Glass kiln

Ceramic tunnel kiln

Cement kiln

FAQ:

Payment term:T/T 30 deposit after order confirmed,the balance after goods ready before shipping,or L/C, or Western Uninon for small amount.

Lead time:Normally in 5-10 days after deposit received

Sample apolicy:Sample are always available for each modle

Shipping port: Tianjing

Technical Data Sheet:

Item | High Alumina Refractory Brick for foundry | |||

0.6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.2 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength (Mpa) ≥ | 2.0 | 2.5 | 3.0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity((W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.80 |

Max Service Temperature (°C) | 1200 | 1280 | 100 | 1350 |

- Q: What is the difference between corundum and high alumina??

- The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: The difference between aluminium refractory and magnesia refractory

- Aluminum refractory belongs to neutral refractory material, usually refers to silicon aluminum refractory materials, such as: high alumina brick, clay brick, high alumina castable and other products, the production of raw materials is mainly bauxite.

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: Are there any differences between insulating bricks and refractory bricks?

- The insulation performance of thermal conductivity of insulating brick in general 0.2-0.4 (average temperature 350 - 25 DEG C) w/m.k, and the thermal conductivity of refractory brick in 1 (the average temperature of 350 - 25 DEG C) above w/m.k, which can obtain the insulation performance of insulating brick than refractory brick insulation performance is much better.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: Does the chimney have high acid resistance?

- If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

Send your message to us

High Alumina Brick for Foundry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords