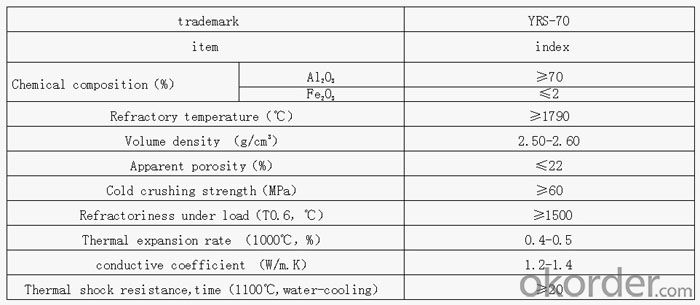

High Alumina Brick - Superior Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Features: Strong volume stability at high temperatures, good thermal shock resistant, wear resistance and chemical attack resistance.

Applications: Transitional zone, reheater of cement rotary kiln and other thermotechnical equipment that requires good thermal shock resistance.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- Quality requirements for aluminium bricks of different grade. 2, high aluminum powder and high alumina aggregate and other materials of reasonable proportion, to reach the production requirements.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- The structural strength of high temperature is evaluated by loading softening point. Load softening point is that under certain pressure (2 kg/ cm 2 = 0.2MPa) under the condition of heating rate to heating, measured the sample deformation (deformation for the original sample 0.6%) temperature. This temperature is called the softening point of the refractory. Sample size is Phi 36 x 50mm.

- Q: What's the weight of the refractory bricks?

- Fireclay refractory bricks: 3.4kg-3.8kg - according to the quality of raw materials, prices ranging from 1 yuan to 2.7 yuan, high alumina refractory brick: three, high aluminum in 3.9kg or so. Ordinary T-3 firebrick weight calculation method: 230*114*65*2.2/2.1.

- Q: What is the difference between high alumina brick and clay brick?

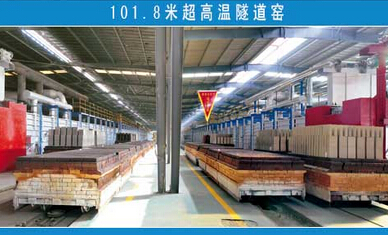

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- First of all, there is a difference in the material, one is clay, and one is high aluminum.Also known as clay brick brick, is a man-made small bulk building, clay brick clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting, solid and hollow.

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: High alumina brick 80 with which high aluminum cement?

- Which kind should be chosen should be determined according to the conditions of use, life expectancy and cost control. By the way, the quality of masonry is also very influential.

Send your message to us

High Alumina Brick - Superior Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords