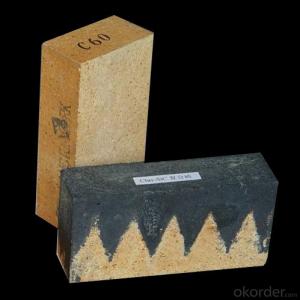

High Alumina Brick - Refractory Fire Brick Magnesia Alumina for Furnace Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Refractory Fire Brick

Refractory Fire Brick Magnesia Alumina for Furnace Liner is widely used in metallurgy, petroleum, chemical industry, building materials, machinery processing, military, etc of thermal technology equipment. Refractory Fire Brick is widely used for MgO Reduction Furnace, Blast furnace, Hot Blast Stove, Tunnel kiln , Steel Ladle, Steel smelting furnace, Coke oven,chimney, Waste incinerators, Casting products, Boilers, Cement kilns, Carbon furnace, Glass kilns and a variety of furnace linings and thermal equipment.etc.

Specifications for Refractory Fire Brick

Item | Refractory Fire Brick Magnesia Alumina for Furnace Liner |

Type | Silica alumina refractory brick Alkaline series Carbon brick Containing zirconium refractory brick Heat insulation refractory brick |

Size and Specifications | NA RNA NK NKI |

Characteristics | Density huge , Strength high Refractoriness under load high Thermal shock resistance best Good eroding resistance Resisting high temperature |

Typical Application

| 1.Building material industry,kiln,heating equipment and the inwall of high—temperature pipe line 2.Chemical industrial high temperature of reaction equipment inwall 3.Power plant ,gas turbine engine and heat insulation of unclear power 4.The fire proof of high—rise building 5.Furnace door of kiln 6.High-temperature filter material |

Operating Temperature | 600°C, 950°C |

Service | the specifications of refractory brick could be customized |

MOQ | 1 ton |

Port | Qingdao Port |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash |

Packing | wooden pallets with water-proof cover, and tightened with plastic/steel bandages |

Delivery | Within 15 Days |

Certificate | CE, ISO 9001 |

Features of Refractory Fire Brick

Low bulk density, low thermal conductivity, good thermal insulation performance.

Refractory category allow direct contact of fire, suitable for various atmosphere.

Good integrity with furnace lining, long service life, easy operation, could be shaped freely.

Typical Application of Refractory Fire Brick

Furnaces of metallurgy industry, heat treatment furnace.

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace .

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: What's the weight of the refractory bricks?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- If the range of softening temperature exceeds the load, the constants of other physical and chemical indexes will also increase or decrease.

Send your message to us

High Alumina Brick - Refractory Fire Brick Magnesia Alumina for Furnace Liner

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords