High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0.3-15 | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.8-1.2% |

| CaO Content (%): | 0.34% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.1-0.3% |

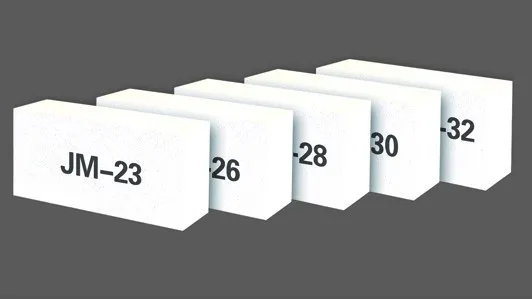

| SiC Content (%): | 1.2-1.4 | Model Number: | JM23 JM26 JM28 JM30 JM32 | Brand Name: | cnbm |

| Name: | insulating Brick | size: | 230*115*65mm | Weight: | 1.19-5kg |

| Color: | white and yellow | Raw material: | mullite & clay | Usage: | Fire resistance place |

| Certificate: | ISO9001 |

Packaging & Delivery

| Packaging Details: | Export wooden pallet or as customers requirements |

| Delivery Detail: | Shipped in 5 days after payment |

refractories insulating bricks mullite bricks

New type quality thermal insulating refractory. It contains alumina 50%-85%, and has mullite (3Al2O3.2SiO2) as major phases and binder phase. Working temperatures are from 1350° C to 1700° C.

Features:

1). High strength as containing high temperature structure

2). Low creep rate at high temperature

3). Low thermal expansion rate

4). Strong resisting chemical erosion performance.

5). Fine resisting thermal shock performance.

3. Property (See below table)

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. High alumina brick refractory clay brick and brick than refractoriness to high. It belongs to high refractory. High alumina brick Al2O3 more, close to the neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so the ability of alkaline slag resistance than acid resistant slag ability is weaker.According to the number of AL2O3 content is divided into, 55,65, 75,80 and so on several grades.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: What's the price of high alumina refractory bricks?

- Their refractory bricks are of good quality and low ex factory prices. Special high alumina refractory brick factory price of 1900 yuan / ton, a high alumina brick factory price of 1650 yuan / ton... This price applies to standard size, size 230*114*65mm, more products, prices go to see.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- Suggest that you use fire brick to increase the length of brick or pull the amount of turn, and use high temperature mortar masonry

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The question is good, these two belong to the high aluminum brick products, when many manufacturers buy, I do not know how to distinguish.

- Q: How to reduce porosity of high alumina brick

- When proportioning, the ratio of coarse to medium to fine is 4:2:4, and the maximum particle size should be no more than 5mm. The mixing order is as follows: first adding coarse particles, then adding sulfite pulp waste liquid, premixed 3min, then adding high aluminum fine powder for mixing. The operation process is coarse and fine particles added in sulfuric acid with crushed pulp waste.In order to reduce the porosity, our company suggested that the single-sided pressure changed to double-sided pressure instead of double-sided pressure, the number of strikes should also vary according to the amount of feeding. If the kiln is fired, the location of the fire hole shall be adjusted so that the middle part is dense, the edge is thin, and the door near the kiln is properly encrypted so that the temperature difference between the furnace top and bottom and the temperature difference between the inside and outside are not greater than 20 degrees.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Fire clay -- usually refers to folk point stove furnace set with a kind of soil, limit under atmospheric pressure of 1500 degrees fire clay soil 1, properties and uses: clay brick of weak acid refractory material, its thermal stability is good, suitable for hot blast furnace, boiler and flue, smoke chamber lining, etc..2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

Send your message to us

High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords