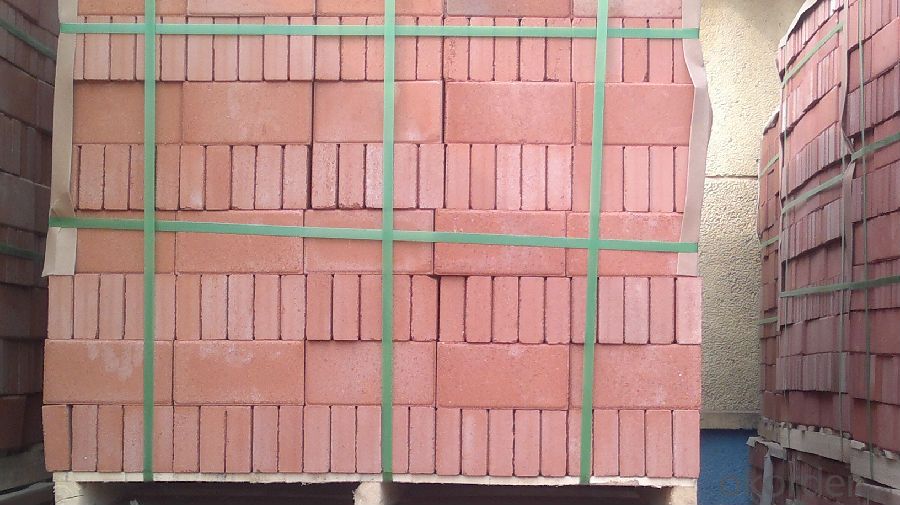

High Alumina Brick - Firebrick Al2O3 Content 30-90%, Dense Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features and advantages:

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

7. Good volume stability at high temperature.

Physical and chemical index:

Item/Grade | Fire clay brick | High alumina brick | |||

SK-30 | SK-32 | SK-34 | SK-36 | SK-38 | |

AL2O3 % (≥) | 30 | 35 | 38 | 55 | 70 |

Fe2O3 % (≤) | 2.5 | 2.5 | 2.0 | 2.0 | 2.0 |

Refractoriness(SK) | 30 | 32 | 34 | 36 | 38 |

Refractoriness under load, 0.2MPa, °C (≥) | 1250 | 1300 | 1370 | 1450 | 1530 |

Apparent porosity (%) | 22-26 | 20-24 | 20-22 | 20-23 | 20-22 |

Bulk density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.25-2.4 | 2.4-2.6 |

Cold crushing strength ,MPa (≥) | 20 | 25 | 30 | 45 | 60 |

Application:

Fire brick is widely used in Blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln, Tunnel kiln,Boiler, Coke oven, Waste incinerators ,Carbon furnace, Glass kiln , Steel smelting furnace and various kiln lining and thermotechnical equipment, etc.

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3.

Send your message to us

High Alumina Brick - Firebrick Al2O3 Content 30-90%, Dense Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords