High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks in Torpedo Car Iron Ladles

Product name, Description, Raw material, Performance & Applications

ASC refractories, short for Alumina-Silicon Carbide-Carbon (Al2O3-SiC-C) refractories, represent a cutting-edge solution for the working lining of torpedo car and iron ladles in the steel industry.

These bricks are meticulously engineered using a premium blend of raw materials, including high-grade bauxite, fused alumina, silicon carbide, graphite, antioxidants, and various additives. Expertly shaped with a phenolic resin binder, they fall under the category of non-burnt carbon composite refractory materials. The production process strictly adheres to dimensional requirements and maintains a strong commitment to high-quality standards.

Our ASC refractories are purpose-designed to excel in the demanding environments of molten metal transportation. They exhibit exceptional attributes such as thermal stability, resistance to alkalis, slag, oxidation, and erosion.

These refractories are primarily used to line hot metal pre-treatment equipment, including torpedo-type mixed iron trucks and iron ladles, during the transfer of molten metal.By choosing our ASC refractory working lining bricks, steel manufacturers can significantly enhance the efficiency and reliability of their torpedo car iron ladles and other metallurgical molten iron pre-treatment equipment.

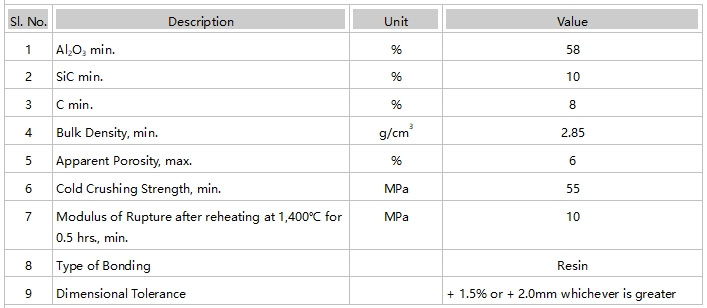

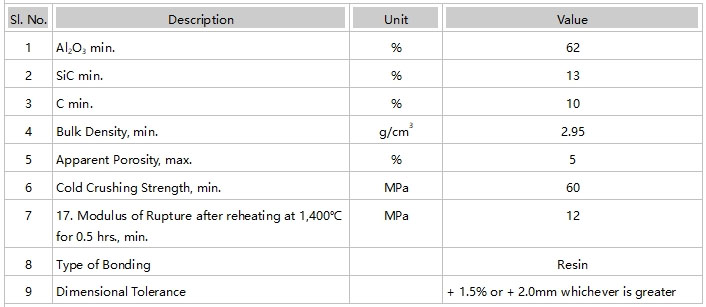

Chemistry and Physical Properties

The following tables present values for the content of Al2O3, SiC and C elements, bulk density, apparent porosity, cold crushing strength, modulus of rupture, type of bonding, and dimensional tolerance for both of the two types of ASC bricks: Standard and Three-removals.

Standard Type ASC Brick

Three-Removals Type Brick

- Three removals, referring to the removal of impurities such as phosphorus (P), sulfur (S), and silicon (Si) from the molten steel during the steel-making process. Three-Removals type bricks are specially designed to have a higher level of purity and lower impurity content than standard bricks.

Packaging

Here are some reference photos showcasing the packaging of our exporting ASC bricks. The ASC bricks are securely enclosed within robust MDF (Medium Density Fiberboard) wooden pallets or cases, with each package measuring approximately 110x100x75cm and weighing approximately 1 ton.

Contact Us

If you have specific requirements for ASC Working Lining, please inform us about the current usage of the product, existing brick types, and other information. We will adjust the content of materials based on your needs and priorities, enabling us to create a product that meets your requirements and budget. If you need us to design the brick shapes, please provide detailed torpedo tank drawings. ASC casting materials can also be produced and provided.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels.

Send your message to us

High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords