High Quality Ceramic Fiber Board 1260STD Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Ceramic Fiber Board

Product Description

General Information

CMAX ceramic fiber boards are manufactured in a wet vacuum forming process by blending the chopped ceramic fiber with inorganic or organic binders for excellent abrasive resistance at high temperature.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000 centigrade,1100 centigrade,1200℃ centigrade and 1350 centigrade.

Feature

Low thermal conductivity

Excellent thermal shock resistance

Excellent chemical stability

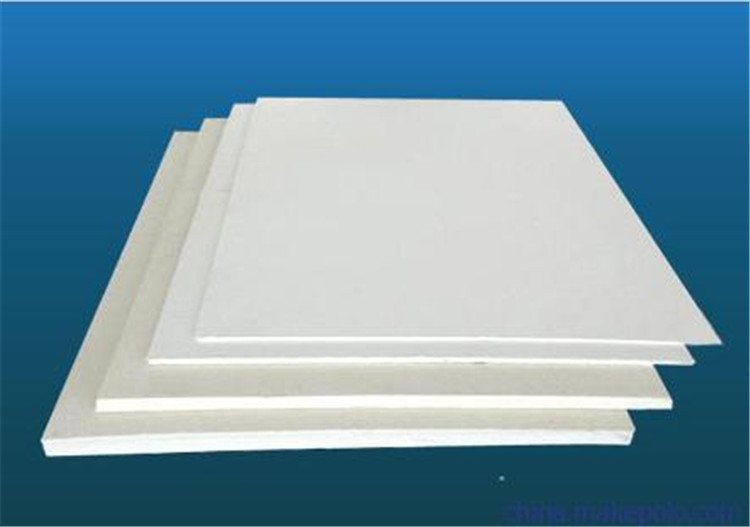

Even density and thickness

Non standard sizes are available upon request

Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Die-cut high temperature seal

Technical data of heat insulation board

Grade | Common | Standard | High Pure | High Aluminium | Zirconium | |

Max. Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | ≤1000 | 1050 | 1100 | 1200 | 1350 | |

Color | White | Pure White | Pure White | Pure White | Pure White | |

Density (kg/m3) | 220-500 | 220-500 | 220-500 | 220-500 | 220-500 | |

Shrinkage on heating (%)(Temperature 24 hours, density as 320kg/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by mean temp. (W/m.k.) (density 285kg/m3) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | 0.085(400°C) | |

Compression strength (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical Composition | AL2O3 | 44 | 46 | 47-49 | 52-55 | 32-33 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 17-18 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2< p=""> | <1.0< p=""> | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size(mm) | 600x400x20-50 ; 900x600x20-50 ;1200x1000x20-50 (Other sizes and shapes on request.) | |||||

Package | Carton box | |||||

Certificates | ISO9001-2008, MSDS | |||||

Packaging & Shipping

Packaging & Delivery

Packaging Details: carton,or according to customer's requirement

Delivery Detail: 30 days after order

Cataloge

We offer a wide range of ceramic fiber products, to cater to a range of domestic and commercial applications.

Ceramic Fiber Blanket:STD,HP,HA,HZ

Ceramic Fiber Board:STD,HP,HA,HZ

Ceramic Fiber Paper:STD,HA,HZ

Ceramic Fiber Module:STD,HP,HA,HZ

Ceramic Fiber Textiles:Cloth,Tap,Yarn,Rope,Square Packing,Ladder,etc

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession

Detailed Images

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

High Quality Ceramic Fiber Board 1260STD Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords