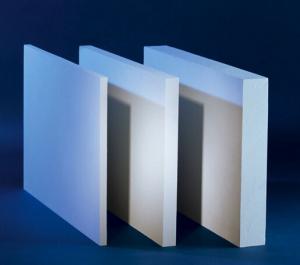

Lightweight Calcium Silicate Board with Ceramic Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details :Calcium Silicate Board with light weight

| Place of Origin: | (Mainland) | Brand Name: | Model Number: | JN | |

| Color: | White | Thermal Conductivity: | ≤0.070+0.00011t | Bulk Density: | 180kg-900kg |

| Flexural Strength: | ≥5Mpa | temperature limit: | 900°C-1100°C |

Packaging & Delivery

| Packaging Detail: | Best wooden pallet package or the cartoon package, all the package we would statisified. |

| Delivery Detail: | 5-15 working days when we received the deposit |

Product Description

1:Good durability, and can withstand high-temperature limit of the continuous thermal load

2:We obtained CE, KR and ISO9001

3:The highest heat resistance temperature is up to 1100 degree centigrade

4:The maximum flexural strength is up to 0.7MPa,all Technical Parameters are the best in China, it is better than other calcium silicate board in the market.

5 Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

Our Services

If you need i could post the sample for you . when you get the sample , you should believe what i said.it is my pleasure to do it.

We promise to all the customer, the customer service would be the best, and good warranty for all the product

Description: High Alumina Bricks with Alumina Content 48% to 90%

Brief discription for high alumina bricks CMAX high aluminia bricks are classified according to alumina content ranging from 48% to 90%. CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for high alumina bricks ◆Low thermal conductivity ◆Excellent acid and base slagging resistance ◆High refractoriness ◆Excellent thermal shock resistance ◆Excellent mechanical strength ◆Good spalling resistance and wear resistance. ◆Good corrosion resistance. ◆High-temperature creep rate is quite low. ◆Good volume stability at high temperature. ◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high aluminia bricks ITEMUAL48UAL55UAL65UAL75UAL80UAL85ALP80Refractoriness, ℃ 1750177017901790181018101810Apparent Porosity,%22222323202018C.C.S, Mpa 394449535560100Refractories Under Load (0.2Mpa),℃ 1420147015001520150015201550Reheating Linear Change,%1450℃x2h 0.1~-0.41500℃x2h 0.1~-0.41500℃x2h 0.1~-0.41500℃x2h 0.1~-0.41550℃x2h -0.5~+0.51550℃x2h -0.5~+0.51550℃x2h -0.5~+0.5Al2O3 Content , %48556575808582

Images/photographs for high alumina bricks

◆ breif images-different shape for different usage ++图 ◆ Packaging for high alumina bricks ++图 ◆ Producing Equipment for high alumina bricks ++图 ◆ Testing Mashines for high alumina bricks ++图

SKYPE:lisaLisa9250

FAQ Q1:Are you a manufacture or trader? A:Factory+trade(mainly factories,at the same time,we operates other related products). Q2:Can we visit your factory? A:Sure,welcome at any time,seeing is believing. Q3:What's the MOQ of trial order? A:No limit,We can offer the best suggestions and solutions according to your condition. Q4:Which payment terms can you accept? A:T/T,L/C are available for us. Q5:After an order is confirmed,when to deliver? A:15-25days after deposit. Q6:Is your company accept customization? A:We have own factory and excellent technical team,and we accept OEM service. Q7:How about your company's certification? A:ISO9001 and Test Report,also we could apply other necessary certification. Q8:How to slove the quality problems? A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it. Q9:Can you offers samples? A:Of coures,samples are free but freight paid by the buyers. Q10:What is the service life of your bricks? A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!! |

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Lightweight Calcium Silicate Board with Ceramic Fiber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords