HDPE Geomembrane Liner - 0.75mm Antiseepage Material HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

1.used in landfill caps.

2.secondary containment for above ground tank farms

3.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes.

Our product was proved as good physical performance, puncture, aging, ultra-violet radiation, oil and salt, alkali and corrosion resistance

, high and temperature resistance, anti-seepage and damp proof effects, complete width and thickness specifications, low cost and simple

construction.

2.Product Characteristic:

1), Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2), Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3), Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

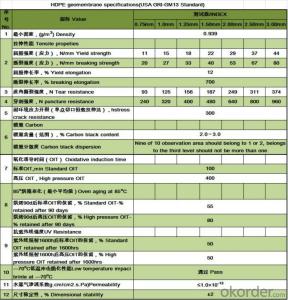

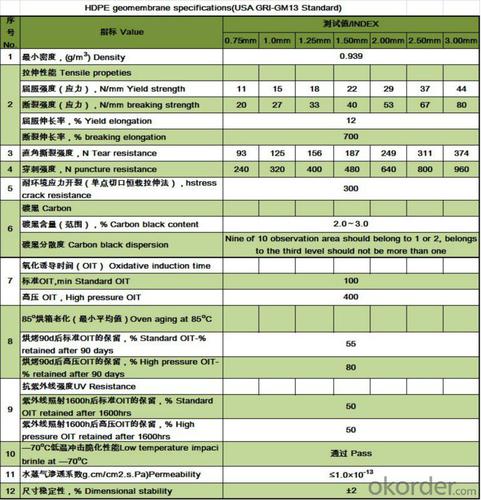

3.Product Specifications:

1.Thickness : 0.75mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Longth:50-100m(at request)

4.Material: HDPE.

5.Color: Black or as required

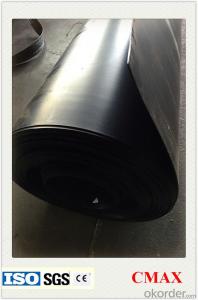

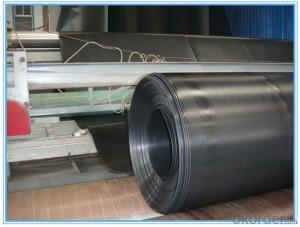

4.Reference Picture

- Q: Does the geomembrane be used as an experiment?

- Geomembrane is to do the experiment, in general, geomembrane manufacturers need to do factory experiments, substandard products can not be manufactured, when the geomembrane transported to the site, the site of the site will do their own experiments, and some sites Will be sent to a dedicated testing organization to do the experiment, the general experiment to take six samples of testing, about each batch of goods to do an experiment 1, test purposes 1. To test the different materials geomembrane solderability and adhesiveness. 2. The welding operators to carry out professional training, so that welding operators to master the geomembrane welding machine technical parameters, working principle, operating procedures and seams of the quality standards, skilled operation of geomembrane welding machine. 3. Determine the welding temperature, crawling speed and operation method of the welding machine under different material conditions. 4. Determine the "T" type lap welding method. 5. Determine the type of adhesive used in geomembrane bonding, manufacturer and construction process. 6. In determining the welder model, welding temperature, crawling speed and other welding construction technology, geomembrane joints of the indicators meet the specification requirements. 7. In determining the binder model, the manufacturer and the construction process, the geomembrane joints of the indicators meet the regulatory requirements. 8. To determine the quality of geomembrane seams detection methods, so that the test staff master master geomembrane seams quality control and testing methods, standards and testing frequency

- Q: Are geomembranes resistant to algae growth?

- Yes, geomembranes are generally resistant to algae growth. Their smooth and impermeable surfaces make it difficult for algae to attach and grow on them. Additionally, geomembranes are often made from materials that are chemically inert and do not provide nutrients for algae to thrive. However, certain factors such as prolonged exposure to sunlight and stagnant water can still create conducive conditions for algae growth on geomembranes.

- Q: Imported HDPE geomembrane application engineering and imported impermeable membrane .

- Landfill; digesters coverage.

- Q: Can geomembranes be used for rainwater harvesting systems?

- Yes, geomembranes can be used for rainwater harvesting systems. Geomembranes, which are impermeable liners made of synthetic materials like HDPE or PVC, can effectively contain and store rainwater. They can be installed in ponds, basins, or tanks to prevent seepage and ensure the collected rainwater is clean and free from contaminants. Geomembranes provide a reliable solution for rainwater harvesting, helping to conserve water resources and promote sustainability.

- Q: Is HDPE geomembrane the uppermost impermeable material used in refuse disposal plant?

- Yes, it is. It has requirement for acid and alkali resistance as well as aging resistance.

- Q: How do geomembranes contribute to the preservation of archaeological sites?

- Geomembranes contribute to the preservation of archaeological sites by providing a protective barrier that helps prevent the degradation and erosion of the site. These synthetic liners are used to cover and isolate the archaeological areas, acting as a barrier against water infiltration, soil movement, and the growth of invasive plants. By preventing these factors from damaging the site, geomembranes help in maintaining the integrity and longevity of archaeological remains, ensuring their preservation for future generations.

- Q: What are the chemical resistance properties of geomembranes?

- Geomembranes are synthetic materials that exhibit excellent chemical resistance properties. They are designed to withstand exposure to a wide range of chemicals, including acids, bases, solvents, and other aggressive substances. The chemical resistance of geomembranes is primarily due to their composition, which often includes high-density polyethylene (HDPE) or other durable polymers. These materials are resistant to degradation, corrosion, and permeation, making geomembranes an ideal choice for containment applications in various industries, such as waste management, mining, and oil and gas.

- Q: How do geomembranes perform in high seismic activity gas containment applications?

- Geomembranes perform well in high seismic activity gas containment applications due to their flexible and durable nature. These membranes are designed to withstand ground movement and vibrations caused by earthquakes, ensuring the integrity of the gas containment system. The elasticity and puncture resistance of geomembranes help prevent gas leaks and maintain the safety and efficiency of gas storage.

- Q: How much money is needed for a geotextile soil

- Lotus root geomembrane 0.4mm new material GB price per square meter 4.7 yuan, an acre needs 710 square feet.

- Q: What are the applications of geomembranes?

- Geomembranes have a wide range of applications across various industries. They are commonly used in environmental containment systems, such as landfills, to prevent the leakage of hazardous materials into the surrounding environment. Geomembranes also play a crucial role in water management projects, such as reservoirs, canals, and ponds, as they prevent seepage and ensure water retention. Additionally, they are utilized in mining operations to line tailings ponds and prevent the contamination of soil and groundwater. Geomembranes are also used in agriculture, aquaculture, and construction projects, where they provide protection against erosion, control fluid migration, and act as a barrier for chemical and gas containment.

Send your message to us

HDPE Geomembrane Liner - 0.75mm Antiseepage Material HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords