Hard Chrome Carbon Steel Round Bar Free Cutting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel round bar:

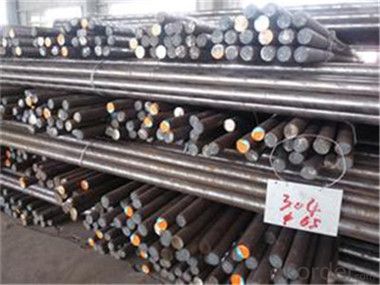

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

Festures of steel round bar:

1.Dia 80-800mm Length:2000-13000mm or as required

2.Technique:Forged

3.Delivery Time:45 days

Specifications of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

4. Standard: GB/T 3077-1999(42CrMo) ; JIS SCM440; DIN 42CrMo4 ; ASTM 4140 ; BS 708M40 Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry,construction,decorate Industry,electric power,pump shafts, sanitary wares,furniture handles,boiler,high temperature resistant,low temperature resistant, corrosion resistant. If you are interested in these products, just feel free to contact us. Our best quotation will be sent without any delay. we sincerely

hope we can establish a long business relationship.

Images of coffee machine:

FAQ:

1. What is your main market?

We mainly export to Asia such as Japan,Korea,Thailand and North America and Middle East.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: On the market, 8mm Round Bar is not 9 meters a root? How much does it weigh about 300 meters? How much does it cost?

- Method of calculating reinforcement weight, unit length, weightD*d*0.00617= (6 in 7)For example, 8mm steel 8*8*0.00617=0.39488 take 0.395Round steel and rib are calculated the same wayRound bar 8 is rolled up, usually between 2~4 tonsYou'll have to straighten it up, straighten it up, and straighten it up

- Q: What is the difference between a centerless ground and a rough turned steel round bar?

- A centerless ground steel round bar and a rough turned steel round bar differ in terms of their manufacturing processes and resulting surface finishes. A centerless ground steel round bar is produced by feeding the bar through a grinding machine that removes material from the surface to achieve precise diameter and roundness tolerances. This process involves rotating the bar between two grinding wheels while applying pressure to remove any imperfections and create a smooth, polished surface finish. The end result is a highly accurate and consistent diameter with a mirror-like finish, making it suitable for applications that require tight tolerances and a polished appearance. On the other hand, a rough turned steel round bar is manufactured through a different machining process called turning. This involves rotating the bar against a cutting tool that removes material from the surface in order to achieve the desired diameter and shape. However, unlike centerless grinding, turning does not provide the same level of precision and surface finish. The resulting surface of a rough turned bar will have visible tool marks and a rougher texture compared to a centerless ground bar. In summary, the main difference between a centerless ground steel round bar and a rough turned steel round bar lies in their manufacturing processes and resulting surface finishes. Centerless grinding offers a more precise diameter, roundness, and smoother surface finish, making it ideal for applications that require tight tolerances and a polished appearance. Rough turning, while less precise and with a rougher surface finish, is still suitable for applications that do not require the same level of precision or aesthetic appeal.

- Q: What is the tensile strength of round steel bars of diameter 28?

- The maximum tensile strength of material resistance uniform plastic deformation, tensile specimens before under maximum tensile stress, the deformation is uniform, but beyond the metal after the necking phenomenon began to appear, which produce concentrated deformation; for no (or very small) brittle materials with uniform plastic deformation, it reflects the fault the resistance of the material. The symbol is Rm (GB/T 228-1987, the old GB standard, the tensile strength symbol is b), the unit is MPa.

- Q: Can steel round bars be used for making universal joints?

- Yes, steel round bars can be used for making universal joints. Steel round bars are commonly used in the manufacturing of universal joints due to their strength, durability, and ability to handle high torque and rotational forces.

- Q: What are the different surface conditions for steel round bars?

- Steel round bars can have a variety of surface conditions, including hot rolled, cold drawn, peeled, polished, and turned. Each surface condition has its own unique properties and appearance, catering to different applications and requirements.

- Q: What are the advantages of using corrosion-resistant steel round bars?

- Using corrosion-resistant steel round bars offers numerous benefits. Firstly, these bars possess a high resistance to corrosion, enabling them to withstand exposure to moisture, chemicals, and other corrosive elements without experiencing significant damage. This makes them ideal for use in environments where the risk of corrosion is high, such as coastal areas or industrial settings. Secondly, corrosion-resistant steel round bars have a longer lifespan compared to regular steel bars. Their ability to resist corrosion ensures that they maintain their structural integrity and strength over time, reducing the need for frequent replacements. This not only saves costs but also minimizes the downtime associated with maintenance and repairs. Furthermore, the utilization of corrosion-resistant steel round bars enhances safety. When steel bars corrode, they can weaken and eventually fail, posing a risk to buildings, infrastructure, and even human lives. By employing corrosion-resistant steel round bars, the risk of structural failures due to corrosion is significantly reduced, ensuring the safety of individuals and property. In addition, corrosion-resistant steel round bars offer versatility in design and application. These bars can be easily fabricated and shaped into various configurations, making them suitable for a wide range of construction projects. They can be utilized in the construction of bridges, buildings, marine structures, pipelines, and many other applications where corrosion resistance is crucial. Lastly, corrosion-resistant steel round bars contribute to environmental sustainability. The longer lifespan of these bars decreases the need for frequent replacements, consequently reducing the demand for raw materials and minimizing waste. Furthermore, their resistance to corrosion results in less maintenance and repair work, leading to lower energy consumption and fewer carbon emissions. In conclusion, the advantages of using corrosion-resistant steel round bars include their resistance to corrosion, extended lifespan, enhanced safety, versatility in design, and positive environmental impact. These qualities make them a cost-effective and dependable choice for various construction and infrastructure projects.

- Q: What are the advantages of using heat-treatable steel round bars?

- Using heat-treatable steel round bars offers several advantages: 1. Strength Enhancement: Controlled heating and cooling processes can be applied to heat-treatable steel round bars, which enhance their strength and hardness. This renders them suitable for applications demanding high strength and durability. 2. Enhanced Resistance to Wear: Heat treatment enables the development of a hardened surface layer on the steel round bars, significantly improving their wear and abrasion resistance. As a result, they are ideal for use in industries such as manufacturing, construction, and automotive, where components experience heavy wear and tear. 3. Tailored Customization: Heat-treatable steel round bars possess the advantage of easy customization to meet specific requirements. By adjusting the heat treatment process, the bars' hardness, strength, and other mechanical properties can be tailored to suit different applications, ensuring optimal performance. 4. Convenient Machinability: Heat-treatable steel round bars generally exhibit good machinability, allowing for easy cutting, drilling, or shaping into various forms without compromising their structural integrity. This convenience reduces production time and costs. 5. Versatility: Heat-treatable steel round bars find versatile applications across a wide range of industries, including construction, manufacturing, oil and gas, automotive, and aerospace. They are commonly utilized in the production of shafts, gears, bolts, axles, and other critical components. 6. Long-term Cost-effectiveness: Although heat-treatable steel round bars may initially have a higher cost compared to non-heat-treatable or lower-grade steels, their durability and enhanced properties make them cost-effective in the long run. The improved strength and wear resistance contribute to a longer service life, reducing the need for frequent replacements and maintenance. In conclusion, the utilization of heat-treatable steel round bars offers a multitude of benefits, including increased strength, improved wear resistance, customized properties, easy machinability, versatility, and long-term cost-effectiveness. These advantages position them as the preferred choice for demanding applications requiring high-performance materials.

- Q: How do steel round bars compare to brass or copper bars?

- Steel round bars typically have higher tensile strength and are more resistant to corrosion compared to brass or copper bars. Additionally, steel is generally a more cost-effective option. However, brass and copper bars offer better electrical conductivity and are often preferred in applications that require good thermal conductivity or an aesthetically pleasing appearance. The choice between steel, brass, or copper bars depends on the specific requirements of the application.

- Q: Can steel round bars be used for making universal joints?

- Yes, steel round bars can be used for making universal joints. Steel round bars are commonly used in the manufacturing of universal joints due to their strength, durability, and ability to handle high torque and rotational forces.

- Q: What is the difference between strip steel and round steel? Where are they mainly used?

- Difference between round bar and other steel bars:(1), is not the same, round shape light round, no pattern without ribs, other steel surface appearance is engraved or ribbed, cohesive force that cause steel and concrete, and the bond strength of steel and concrete in the other.(2) the composition is different. Round steel (grade a steel) belongs to ordinary low carbon steel, and most other steel bars are alloy steel.(3), the strength is not the same, low strength steel, and other steel with high strength, the diameter of the same size as compared with other steel, round steel can bear the pulling force than other reinforced small, but the plastic steel reinforced bar is stronger than the other, there is a large deformation in the break before, while the other bars in the break before the deformation is much smaller.

Send your message to us

Hard Chrome Carbon Steel Round Bar Free Cutting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords