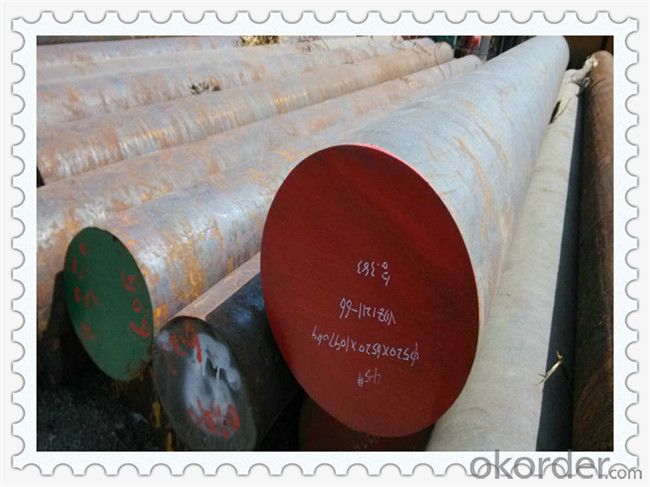

H13 Forged Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H13 Forged Steel Round Bar

Material: |

h13 forged steel round bar

|

Comparative standards: JIS SKD61,AISI/ASTM H13,Nr.W 1.2344.DIN X40CrMoV5, GB 4Cr5MoSiV1

| |

hot work tool steel h13 Chemical Composition as following or customized CSiMnCrSPMoV0.400.950.355.00.030.031.100.85 | |

Diameter: |

hot work tool steel h13 round bars size range : GradeH13 Hot rolled size range: Dia 16mm-45mm Forged size range: Dia50mm-650mm Max dia800mm EFS size range:Dia16mm-480mm Min dia16mm ESR size range:Dia16mm-800mm

hot work tool steel h13 flat bars size range: GradeH13 Hot rolled size range:thickness 15mm-45mm Width :Max 610mm Min thickness15mmForged size range:thickness 50mm-450mmMax thickness500mmWidth :Max 1400mm EFS size range:thickness 15mm-280mm Min width105Width: max 800mmMax width2000mmESR size range:thickness 15mm-450mm Width: max 2000mm

hot work tool steel bar h13 square bars size range : GradeH13 Hot rolled size range:max45mm Forged size range:50mm-650mm Max square650mm EFS size range: max square 500mm ESR size range: max square 650mm

|

Length: |

2000mm-5800mm of fix length as customized , Straightness: 3mm/M max;

|

Process: |

EAF + LF + VD +(ESR) + Forged +annealed condition (optional)

|

Delivery condition: |

Hot forged +Rough machined + Turned (as for round bars) / milled in four faces (as for steel plates or flat bars)

|

Delivery Time: |

20 days

|

MOQ: |

3 tons

|

Heat treatment: | Normalized / Annealed / Quenched / tempered |

Forged ratio: |

no less than 4:1

|

Technical Data: |

According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

|

Test: |

Ultrasonic test according to SEP 1921-84 G3 C/c

|

Certificate of Quality |

in addition the normal terms, production process, the mechanical property forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality

|

Marking: |

Grade, heat NO. length will be stamped one each bar with required color

|

Payment: |

30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight

|

Application of tool steel H13: |

hot extrusion dies, forging die forging hammer, forging press die, precision forging die well as aluminum, copper and alloys die-casting mold.

|

- Q: How do steel round bars compare to ceramic round bars?

- Steel round bars are generally stronger and more durable compared to ceramic round bars. Steel has a higher tensile strength and can withstand higher temperatures, making it suitable for heavy-duty applications. On the other hand, ceramic round bars are generally lighter, offer better corrosion resistance, and have higher electrical insulation properties. The choice between steel and ceramic round bars depends on the specific application requirements and desired properties.

- Q: 20 round bars are of several grades

- No. 20 cold drawn steel belongs to high quality low carbon steel, cold extrusion, carburizing hardened steel. The steel has low strength, toughness, plasticity and weldability. The tensile strength is 355-500MPa, elongation is greater than or equal to 24%.

- Q: What is the difference between a hot-finished and a cold-finished steel round bar?

- The main difference between a hot-finished and a cold-finished steel round bar lies in the manufacturing process. A hot-finished steel round bar is produced by heating the steel billet or ingot to high temperatures and then rolling it into the desired shape. This process results in a rougher surface, with the bar exhibiting a scale or oxidation layer. On the other hand, a cold-finished steel round bar is produced by further processing the hot-finished bar through additional steps like cold drawing, turning, grinding, or polishing. This process enhances the dimensional accuracy, surface finish, and mechanical properties of the bar. The cold-finished bar has a smoother surface and tighter tolerances, making it suitable for applications that require precision and a higher-quality finish. In summary, while both hot-finished and cold-finished steel round bars serve the same purpose, the cold-finished bar offers improved dimensional accuracy, surface finish, and mechanical properties due to additional processing steps.

- Q: What are the advantages of using rust-resistant steel round bars?

- There are several advantages of using rust-resistant steel round bars. Firstly, they have a longer lifespan compared to regular steel bars as they are less prone to corrosion. This makes them ideal for outdoor applications or in environments with high humidity or exposure to water. Secondly, rust-resistant steel round bars require less maintenance and upkeep, saving both time and money. Additionally, these bars provide enhanced structural integrity and strength due to their resistance to corrosion, making them suitable for heavy-duty applications. Finally, using rust-resistant steel round bars ensures the aesthetics of the structure as they retain their appearance and do not develop unsightly rust stains over time.

- Q: How are steel round bars measured and specified?

- Steel round bars are measured and specified based on their diameter, which is typically expressed in millimeters or inches. The measurement is taken across the widest point of the circular cross-section of the bar. In addition to the diameter, the length of the bar is also specified. The measurements and specifications are crucial in determining the appropriate size and quantity of steel round bars required for a particular application or project.

- Q: What are the limitations of using steel round bars?

- There are several limitations to using steel round bars. Firstly, steel round bars have a limited strength-to-weight ratio, which means they may not be suitable for applications that require high strength and low weight. Additionally, steel round bars can be prone to corrosion and rust if not properly protected or maintained. Another limitation is their inability to be easily shaped or bent, making them less flexible for certain design requirements. Lastly, steel round bars may not be cost-effective for small-scale or low-budget projects due to their higher material and manufacturing costs compared to other alternatives.

- Q: Can steel round bars be used in the production of springs?

- Yes, steel round bars can be used in the production of springs. Steel is a common material used in the manufacturing of springs due to its high strength and durability. Steel round bars are often used to create the base material for springs, as they can be easily shaped and formed into the desired spring shape. Additionally, steel round bars can be heat-treated to enhance their mechanical properties, making them suitable for various spring applications. The specific type of steel used will depend on the desired characteristics and requirements of the spring, such as the desired level of flexibility and resistance to deformation. Overall, steel round bars are widely utilized in the production of springs due to their excellent mechanical properties, making them a suitable choice for many spring applications.

- Q: Can steel round bars be used for making oil and gas industry components?

- Yes, steel round bars can be used for making oil and gas industry components. Steel round bars are commonly used in the oil and gas industry due to their high strength, durability, and resistance to corrosion. These components require materials that can withstand harsh environments, high pressures, and extreme temperatures, and steel round bars meet these criteria. They are commonly used to manufacture various components such as valves, flanges, pipes, and fittings, which are vital for the functioning of the oil and gas industry. Additionally, steel round bars can be easily machined and welded, allowing for the fabrication of complex shapes and structures required in this industry. Overall, steel round bars are a reliable and widely used material for making oil and gas industry components.

- Q: Can steel round bars be used in high-pressure applications?

- Yes, steel round bars can be used in high-pressure applications. Steel is known for its strength and durability, making it suitable for withstanding high-pressure environments. Additionally, steel round bars can be manufactured to specific tensile and yield strengths, allowing them to meet the requirements of various high-pressure applications.

- Q: How do steel round bars resist corrosion?

- Steel round bars resist corrosion through a combination of factors. Firstly, steel itself is an alloy made primarily of iron and carbon, and the addition of other elements such as chromium, nickel, and molybdenum enhances its corrosion resistance. These alloying elements form a protective oxide layer on the surface of the steel, which acts as a barrier against corrosive elements in the environment. Furthermore, steel round bars can undergo additional surface treatments or coatings to further enhance their resistance to corrosion. One common method is galvanization, where the steel is coated with a layer of zinc. This zinc coating serves as a sacrificial layer, corroding first before the steel itself is affected. Additionally, steel round bars can be coated with epoxy or other polymer coatings to provide an extra layer of protection. It is also important to note that the manufacturing process and quality of the steel round bars play a significant role in their corrosion resistance. Proper heat treatment, refining processes, and quality control measures ensure that the steel has a homogeneous microstructure and minimal impurities, reducing the likelihood of corrosion. Overall, the combination of alloying elements, surface treatments, and quality manufacturing processes contribute to the corrosion resistance of steel round bars, making them a reliable choice for applications in corrosive environments.

Send your message to us

H13 Forged Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords