Graphite Powder Pinewood Derby - Natural Flake Graphite (Expandable Graphite)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

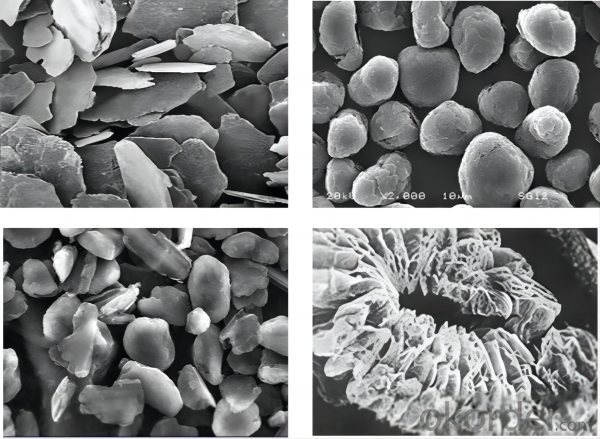

Natural Flake graphite

Relying on the advantages of liumao graphite resources, we develop deep processing of natural

graphite. The main products include fine graphite powder, natural graphite anode materials for

lithium-ion batteries.

The production capacity is:

1). 100,000 ton of fine graphite powder;

2). 50,000 tons of natural spherical graphite;

3). 50,000 tons of Purifying capacity;

4). 40,000 tons of anode materials;

5). 10,000 tons of expanded graphite, graphene, silicon-carbon anode and other graphite

deep-processing products. Our products have been continuously exported to over 30 countries

including the United States, the UnitedKingdom, India, Japan, and South Korea etc.

Product Range:

•Graphite fine powder- Mainly used in the production of refractory materials,

main products: -193, -194, -195, 196, +195, +895, +595, etc. more than 80 varieties.

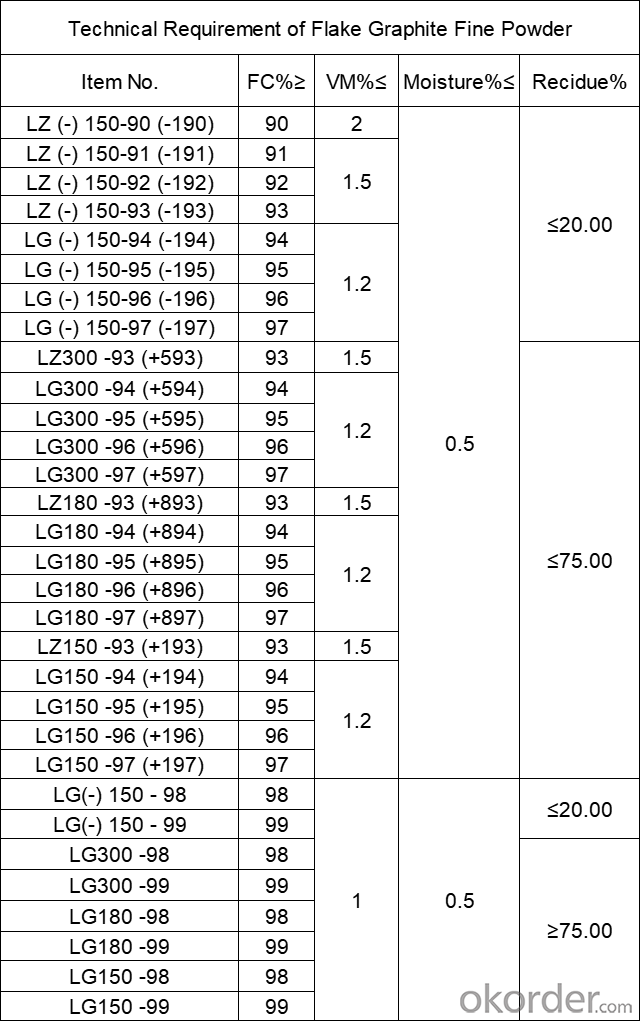

For details, please check Table 1.

Table 1:

•Graphite deep processing products - Natural graphite negative electrode materials,

main products:

1. Spherical Graphite GS8, SG10, SG16, SG17.

2. Negative electrode material MSG10, MSG16 and MSG17 etc. more than 10 products .

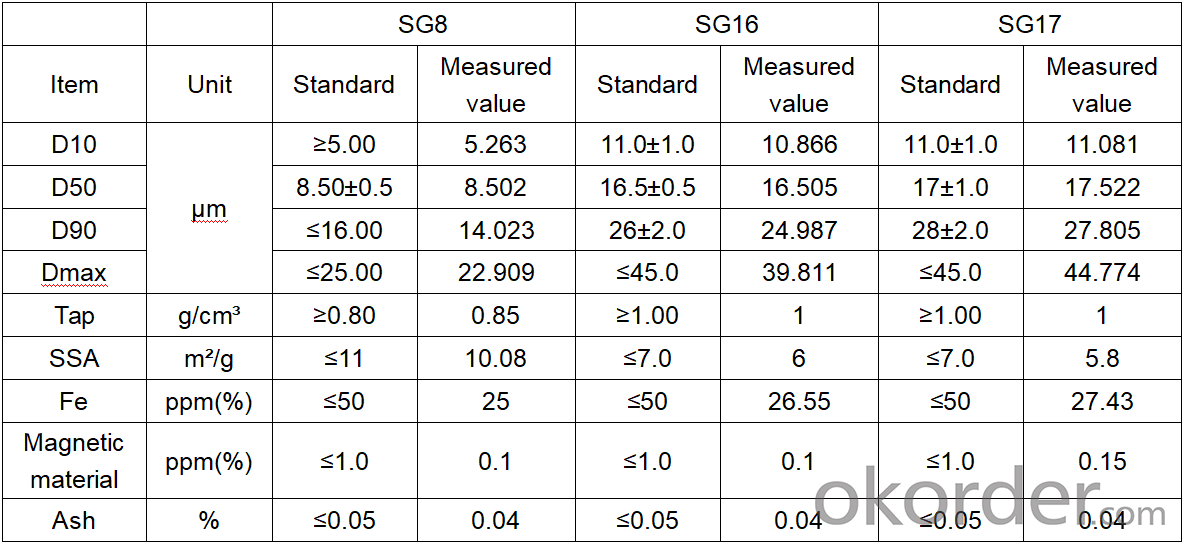

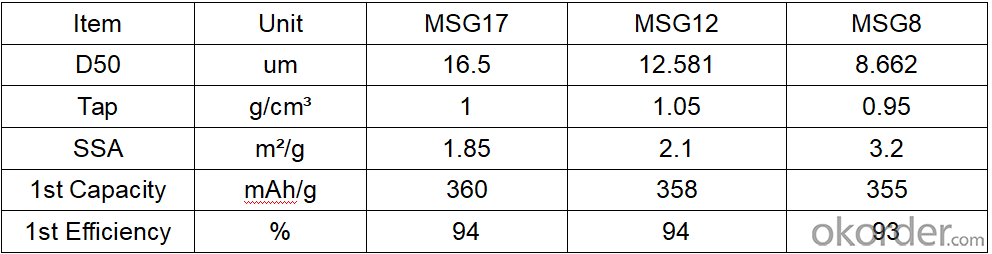

For details, please check Table 2 and Table 3.

Table 2: Spherical Graphite

Table 3:Negative electrode material

Advantages:

•Resource:

1.Proven resource storage is 236 million tons, possess graphite mining rights.

2.It is a rare high-quality large flake graphite resources in the world.

•Production:

1.Annual production capacity is 80,000 tons.

2.Possess substations, tailings ponds, and special railway lines

3.Mature production technology, deeply cultivated graphite mining and selection for more than 80 years.

- Q: Thermal conductivity and density of graphite powder

- For the same type of graphite, the thermal conductivity increases with increasing density, and Figure 11 shows the relation between the density of HDFG and the density of the same graphite.The heat treatment temperature of polycrystalline graphite is mostly made by roasting the semifinished material by high temperature heat treatment. The higher the heat treatment temperature is, the more perfect the crystallite growth is, the La increases, and the thermal conductivity also increases. With calcined petroleum coke and coal tar pitch, roasting sticks made of extrusion, after different heat treatment (HTT), the value of La are shown in Table 4. The axial thermal conductivity will change with temperature is shown in figure 12. The reciprocal of thermal conductivity 1/ lambda is called thermal resistance. At different temperatures, the relationship between the axial thermal resistance of graphite is shown in Figure 13 and l/La / 1/.

- Q: What's the conductivity of graphite powder, silver powder?

- The resistivity of graphite is approximately (8~13) * 10-6.M at room temperature

- Q: Can you tin to latex paint

- Yes, it's better to paint with antirust paint and putty,

- Q: How does graphite powder look good or bad?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5. The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

- Q: For thermal grease skills, the more detailed the better

- If the fins and the metal cover of the CPU are as smooth as mirrors, they will be 100 percent fully exposed to the best thermal conductivity.

- Q: Distinguish iron powder and graphite powder by chemical method

- Add dilute sulfuric acid, there is a bubble generated iron powder, the phenomenon is Shi Mofen

- Q: What solvent can be used to dissolve Teflon?

- PTFE is not dissolved after Teflon, it is impossible to mix with graphite powder this thing.

- Q: Why can graphite powder conduct electricity?

- Graphite is a crystalline mineral of carbonaceous elements. Its crystalline framework is hexagonal layered structure. The distance between each network layer is 3.40, and the distance between the carbon atoms in the same network layer is 1.42A. Of the six Fang system with a complete lamellar cleavage. The cleavage surface is mainly based on molecular bonds, and has weaker molecular attraction, so its natural floatability is very good.

- Q: The axis and drum can use graphite powder lubrication

- No, graphite powder is suitable for high temperature environment, and the lubricating effect is better than that of lubricating oil

- Q: Graphite powder made of graphite oxide, how much weight gain?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5.

Send your message to us

Graphite Powder Pinewood Derby - Natural Flake Graphite (Expandable Graphite)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches