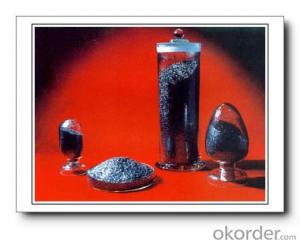

Flake Graphite Powder - Natural Flake Graphite +195 Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Natural Flake Graphite :

Types:High-purity graphite,high carbon grahite.

Specifications:The particle size ranges from (325mesh-35mesh)

and the carbon content ranges from85 to 99.9%.

Regular Index of Natural Flake Graphite :

Packaging & Shipping of Natural Flake Graphite :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Usage of Natural Flake Graphite :

Crystalline flake graphite is widely used as an essential nonmetalic mineral in almost all industries.It can be used as high-quality refractory material or coatings in metallurgical industry,black lead in light industry,carbon brush in electronics industry,electrode in battery industry and catalyst in chemical fertilizer industry, to name just a few.After being deep processed,crystalline flake graphite can be used to produce TV tube coatings, graphite friction reducing additives and many other high-tech products.Main Technical Index:See tables attached.High Carbon Graphite

- Q: How does graphite powder solidify into a lump? What bond is best used?After solidification can be more than 1000 degrees high temperature does not change

- The only way to do this is by using physical methods, high temperature and high pressure, to agglomerate the graphite powder from the molecular level. Now, by simulating the high temperature and pressure of the earth's crust, graphite can be turned into diamond (that is, diamonds)

- Q: Thermal conductivity and density of graphite powder

- In the formula, P is porosity, and lambda 0 is the thermal conductivity without hole (P=0). This formula is of historic significance. For graphite, the pores are not spherical or more unequal, but of course they do not apply. But it shows that the larger the porosity (the smaller the density), the smaller the thermal conductivity. This qualitative conclusion is correct. An extruded graphite core with different impregnation treatments

- Q: How to measure the conductivity of powdered graphite?

- Some other factors for measuring the resistivity of conductive graphite powderConductivity varies with external factors and is sensitive. The early microphones were made with graphite powder, because the vibration of the voice changed the electrical conductivity between the graphite powders and changed the current to produce analog signals. One can imagine that you need to test his electrical conductivity for the experimental environment.

- Q: Whether the lubricating oil toner is coupled with the conductor?

- Not really. It depends on the amount of graphite powder. If the graphite powder forms a continuous through zone, it can be considered a conductorYou can use lubricating oil, preferably not with graphite, which will cause the sliding rheostat to fail

- Q: Are graphite powders soluble in water, dilute acids, dilute bases, and organic solvents?

- Under heating, the graphite powder is more easily oxidized by acid. At high temperature, it can react with many metals to produce metal carbides, which can smelt metals at high temperature

- Q: How to deal with graphite powder? Anyone recycle it?

- We have a lot of graphite, and now we have it

- Q: Why can graphite powder conduct electricity?

- Graphite is a crystalline mineral of carbonaceous elements. Its crystalline framework is hexagonal layered structure. The distance between each network layer is 3.40, and the distance between the carbon atoms in the same network layer is 1.42A. Of the six Fang system with a complete lamellar cleavage. The cleavage surface is mainly based on molecular bonds, and has weaker molecular attraction, so its natural floatability is very good.

- Q: The processing technology of graphite powder is different, will the price of graphite powder be different?

- The production process of graphite powder is different: graphite powder production process has many, different production process makes the cost of graphite powder increase, so the price of graphite powder has been unstable.

- Q: Does the graphite powder cause explosion? If so, how to prevent the production of graphite products in the workshop?

- Flammable dust is suspended in the air at an appropriate concentration to form dust clouds that are commonly called;All the solid matter which is fine powder is called dust. The dust that burns and explodes is called combustible dust; the dust floating in the air is called suspended dust; the dust deposited on the solid wall is called sedimentary dust.With explosive dust: metal (such as magnesium, aluminum); coal; grain (such as wheat, starch); feed (such as blood meal, fish meal); agricultural and sideline products (such as cotton and tobacco); forest products (such as paper powder, wood flour); synthetic materials (such as plastics, dyes).

- Q: Refractive index and absorbance of graphite powder

- When the matter to be measured is different, or the wavelength chosen is different, the molar absorption coefficient will be different, so that it can not meet the quantitative relationship of Bill's law.

Send your message to us

Flake Graphite Powder - Natural Flake Graphite +195 Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords