Graphite Electrode Rp - Ready Stock Factory Price for Steel Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Graphite Electrode

Graphite electrode is made from the domestic first class petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The Graphite electrodes include: regular power, high power, ultra high power and square electrode. The range of diameters covers from 200mm to 800mm. Our products own the following characteristics: low electric resistivity, good electrical and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

CNBM and its partner have 4 production bases and the annual production capacity of graphite electrodes is 60,000 MT.

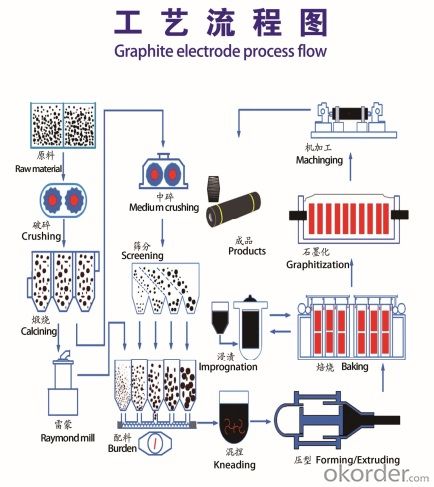

Graphite Electrode Process Flow

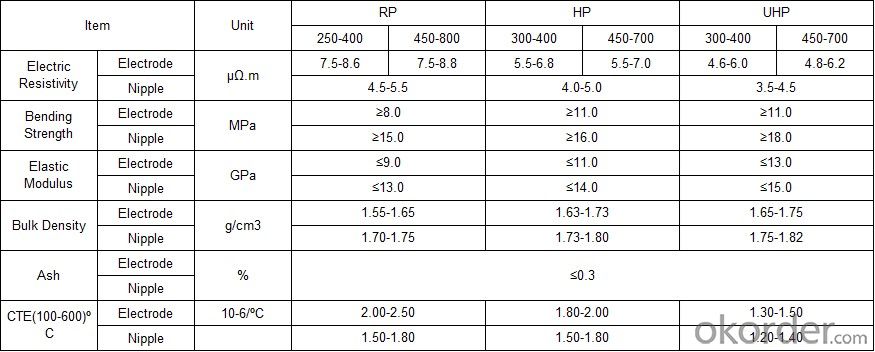

Technical Specifaication:

Company Profile

CNBM INTERNATIONAL CORPORATION

Build your world with our materials.

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019). We have more than 300 factory plants in China. For the refractory, we are top 3 in China. We have more than 17 plants in different cities.

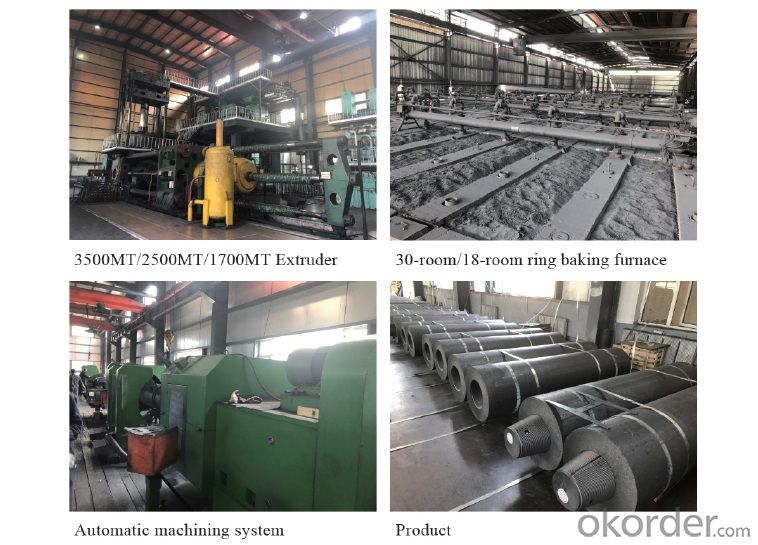

Production Facilities

Quality Assurance & Control

· National Certified Laboratory

· Key testing instruments, including: specific resistor, bulk density meter, elasticmodulus meter, bending strength inspector, ash analysis meter, CTE analysis meter, etc.

· On-time instrument calibration

· On-site properties testing, including:

L-CTE,C-CTE

Specific resistance, bulk density,

Bending strength, ash content, elastic modulus

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: Is graphite electrode good for foreign trade?

- I do graphite electrode production, but also do trade. The profit depends on the price you talked about. It should be around 2000.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- The technical development of the high-speed machining center lays the foundation for improving the milling efficiency and quality of the graphite electrode, especially for the milling of the small electrode with complicated shape and thin wall. In the EDM mold processing, the graphite electrode needs to be processed by the high-speed machining center (HSM), so the demand for HSM machine tools is also increasing. But for some time, because of the technological developments in hard steel processing, it seems possible to make graphite electrodes an obsolete technology.

- Q: Why graphite can be used as conductive material?

- Lubricants can not be used in high speed, high temperature, high pressure conditions, and graphite wear-resistant materials can be at the temperature and at a high sliding speed, without lubricating oil work. Many transporting corrosive media devices are widely used, which is made of graphite material piston ring, the sealing ring and the bearing, they are running, without adding lubricating oil, graphite and many metal processing when good lubricant.

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- There's no way. It's an industrial problem, and that's how graphite works.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- No, sodium sulfite reacts with the oxygen produced.

- Q: National standard for graphite electrodes

- Page 7 the international standard specifies the shape, dimensions and tolerances, technical requirements, test methods, packaging, marking, storage, transportation and quality certificates of graphite electrodes. This standard applies to high quality petroleum coke, asphalt, coke as the main raw material, through molding, roasting, impregnation, graphitization and mechanical processing made of, power supply arc furnace as conductive material of ordinary power graphite electrode. Common power graphite electrode GB

- Q: Graphite electrode press device

- Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- The utilization ratio of graphite energy can reach more than 95%. Many kinds of antioxidant paint, it is recommended to directly find their technicians, you can give professional advice, according to the actual situation, the reasonable use of high-temperature oxidation resistant paint.

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- Overhead wires, radiating the best conditions, allowed the current largest. The insulated wire in the house is laid in the wall, which has the worst heat release conditions and the smaller permissible current, so there are different safety currents.

Send your message to us

Graphite Electrode Rp - Ready Stock Factory Price for Steel Making

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords