Grade Galvanized Steel Coil with CE Approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

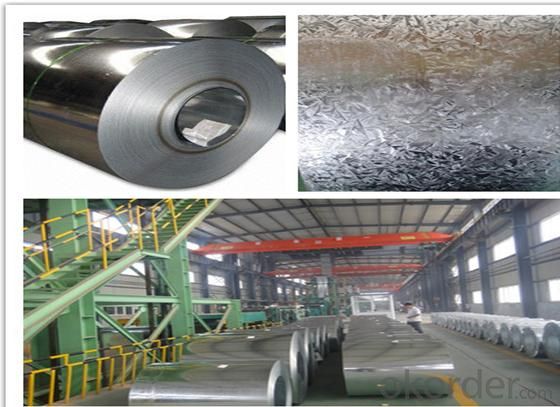

Model NO.:DX51D, SGCC, DX52D

Type:Steel Coil

Technique:Hot Dipped

Standard:ASTM, AISI, GB, JIS, DIN, BS

Surface Treatment:Galvanized

Special Use:Wear Resistant Steel

Application:Ship Plate, Container Plate

Thickness:0.13-4mm

Width:600-1500mm

Zinc Coating:60-275G/M2

Grade:Dx51d, SGCC, Sgch, A653, Dx52d, Dx53D

MOQ:5tons

Certificates:BV, SGS, ISO, CE, Ciq

Stock:Yes

Sample:Free

Spangle:Minimum, Zero, Big, Regular

Export Markets:Global

Additional Info.

Trademark:Sino Steel

Packing:Standard Seaworthy Export Packing

Standard:DX51D, SGCC, SGCH, A653

Origin:Shandong

HS Code:721049000

Production Capacity:1000 Tons/Day

Product Description

Specification:

1. Thickness: 0.11mm-3mm

2. Width: 600mm-1500mm

3. Length: According to client's demands

4. Inside Diameter: 508mm/610mm

5. Outside Diameter: 1000mm-1500mm

6. Coil weight: 3-8 tons

7. Payment: T/T, L/C, D/P, Paypal, Western Union

8. Trade Term: FOB, CFR, CIF

9. MOQ: 25 Mt

10. Package: Export standard package or as request

11. Shipment: By container

12. Standard: AISI, ASTM, BS, DIN, GB, JIS

13. Grade: SPCC/SPCD/SPCE/ST12-15/DC01-06

Our advantage

1. Certificate: ISO, BV, CE, SGS

2. Feedback within 24 hours

3. Best price from our own factory

4. Quick delivery

5. Stock and production

6. Cooperation with BAO STEEL and LAIWU STEEL

7. Experience for many years, specilized in manufacturing and exporting

8. Customers from many continents, such as North America, South America, Europe, Africa, etc

9.Flexible payment with T/T,L/C,Kunlun bank

Take customers as the honoured, Take quality as the foundation!

Strive For Survival On The Basis Of Quality!

| Name | Galvanized steel coil |

| Standard | AISI,ASTM,GB,JIS |

| Material | SPCC/SPCD/SPCE/ST12-15/DC01-06. |

| Thickness | 0.13-4mm |

| Width | 600-1500mm |

| Tolerance | "+/-0.02''mm |

| Surface treatment: | galvanized |

| Coil ID | 508mm/610mm |

| Coil Weight | 3-8 tons |

| Technique | Cold rolled |

| Package | seaworthy package |

| Certification | ISO 9001-2008,SGS,CE,BV |

| MOQ | 25 TONS (in one 20ft FCL) |

| Delivery | 15-20 days |

| Monthly Output | 10000 tons |

| Description | The cold rolling reduces the thickness of the steel and at the same time changes the mechanical properties of the steel. Cold rolled steel must be further processed, as the steel will react with water in the air and form rust. In most cases, it is covered with a thin layer of oil to prevent oxygen reacting with surface. The steel coils can be annealed (heated in a controlled atmosphere) to make the steel more formable (cold rolled annealed) or further processed on the metallic coating line, with a coating of either zinc (galvanized) or zinc-aluminium alloy applied. Cold rolled steel is available in a range of grades, each with a range of properties for differing applications. |

| Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

| Remarks | Insurance is all risks and accept the third party test |

- Q: I mean, besides the light weight and other graces of Aluminium and Carbon, Steel frames are absolutely out-dated and they have nothing to do these days... or it is still possible to enjoy a nice ride on our heavy old pals?

- Ah, I took a nice 40mi spin on my steel road bike today. Maybe it's not as fast as my other rides...I don't know, I'm too busy enjoying the ride. Steel is timeless.

- Q: What are the common applications of cold-rolled steel coils?

- Due to its exceptional qualities, cold-rolled steel coils find a wide range of common applications across various industries. The automotive industry extensively uses these coils to manufacture car parts like body panels, chassis components, and structural reinforcements, benefiting from the high strength and excellent formability of cold-rolled steel. Similarly, the construction industry relies on cold-rolled steel coils to fabricate structural elements for buildings and infrastructure. Beams, columns, and other load-bearing components are commonly made from cold-rolled steel due to its superior strength and durability. Appliances and consumer goods manufacturing also make use of cold-rolled steel coils. They are frequently employed to create the outer shells of refrigerators, washing machines, and ovens, thanks to the smooth and consistent surface finish that provides an aesthetically pleasing appearance. Furthermore, the electrical industry utilizes cold-rolled steel coils in the production of electrical enclosures, transformers, and various other components. The excellent electrical conductivity and magnetic properties of cold-rolled steel make it a preferred choice for such applications. In summary, cold-rolled steel coils have diverse applications in industries including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it the favored choice for manufacturers across various sectors.

- Q: How are steel coils inspected for surface cleanliness after processing?

- Steel coils are inspected for surface cleanliness after processing through visual inspection methods, such as using bright lights and magnifiers to spot any visible contaminants or defects. Additionally, various non-destructive testing techniques, like ultrasonic testing or magnetic particle inspection, may be employed to detect any hidden surface irregularities or contaminants.

- Q: What are the cost implications of using steel coils in manufacturing?

- The cost implications of using steel coils in manufacturing can vary depending on several factors. Firstly, the cost of purchasing steel coils themselves can have a significant impact on overall manufacturing expenses. Steel prices are influenced by factors such as supply and demand, global market conditions, and any tariffs or trade regulations in place. Fluctuations in steel prices can directly affect the cost of purchasing steel coils, which in turn affects the overall manufacturing cost. Additionally, the size and weight of steel coils can impact transportation costs. Steel coils are typically heavy and bulky, which can incur higher shipping expenses due to increased transportation requirements. The distance between the steel supplier and the manufacturing facility can also influence shipping costs. Furthermore, the processing and transformation of steel coils into finished products can contribute to manufacturing costs. Additional steps such as cutting, shaping, welding, or coating may be required depending on the desired end product. These additional processes can require specialized machinery, skilled labor, and additional materials, all of which can add to the overall manufacturing expenses. It is also essential to consider the quality and durability of steel coils. While using high-quality steel coils may initially result in higher costs, it can lead to long-term cost savings by reducing the need for repairs or replacements. Moreover, it is crucial to factor in any regulatory or compliance requirements associated with using steel coils in manufacturing. Certain industries may have specific standards or certifications that need to be met, which can involve additional costs for testing, inspections, or compliance procedures. Lastly, it is important to consider the potential cost savings that steel coils can offer in terms of efficiency and productivity. Steel coils are often preferred in manufacturing due to their strength, durability, and ease of fabrication. These qualities can lead to improved production processes, reduced waste, and higher overall output, which can offset the initial cost of using steel coils. Overall, the cost implications of using steel coils in manufacturing can be influenced by several factors such as steel prices, transportation costs, additional processing requirements, quality considerations, regulatory compliance, and potential productivity gains. Careful analysis and consideration of these factors are crucial in understanding the overall cost impact on manufacturing operations.

- Q: What are the main applications of steel coils?

- Steel coils have a wide range of applications, but their main uses include manufacturing various types of machinery and equipment, construction of buildings and infrastructure, automotive industry for manufacturing vehicles, electrical appliances, and packaging materials.

- Q: Can steel coils be stored in a corrosive environment?

- No, steel coils should not be stored in a corrosive environment as it can lead to the degradation of the steel surface and compromise its structural integrity.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try a local Fastenal store, they can order it for you by the sheet. If that doesnt help, then try a welding or fabricating store.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry include coil cradles, coil cars, coil reels, coil straighteners, coil feeders, and coil tippers. These equipment are used to efficiently and safely handle coils of various sizes and weights during manufacturing processes.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2 and 1.7 or 2.04% by weight (C:1000–10,8.67Fe), depending on grade. Steel is Fe(iron) and Carbon alloy. These are the atoms in certain ratio that make up steel. Its not a molecule but alloy.

- Q: What are the common methods of transporting steel coils?

- There are several common methods of transporting steel coils, depending on the distance, quantity, and specific requirements of the shipment. The most commonly used methods include: 1. Flatbed trucks: This is the most basic and widely used method for short-distance transportation of steel coils. Flatbed trucks have a flat, open trailer bed that allows for easy loading and unloading of the coils. The coils are secured and strapped down to prevent movement during transit. 2. Rail transport: For longer distances, rail transport is often preferred due to its cost-effectiveness and efficiency. Coils are loaded onto specially designed railcars, known as coil cars or gondola cars, which have curved troughs or cradles to hold the coils securely in place. This method is particularly advantageous for large quantities of steel coils. 3. Ocean freight: When transporting steel coils internationally or over long distances across oceans, shipping by sea is a common method. The coils are typically loaded into specialized shipping containers, known as coil containers or coiled steel containers, which have internal cradles to prevent movement and damage during transit. These containers are then loaded onto cargo ships for transportation. 4. Barge transport: In regions with navigable waterways, barges can be used to transport steel coils. Similar to ocean freight, the coils are loaded into specially designed containers or barges with cradles to secure them during transport. Barges offer an economical and environmentally friendly option, especially for inland waterway transportation. 5. Intermodal transport: In some cases, a combination of different modes of transportation may be used for transporting steel coils. This is referred to as intermodal transport. For example, steel coils may be initially transported by truck to a rail yard, where they are then loaded onto railcars for long-distance transport. This method allows for the advantages of different modes of transportation to be combined, optimizing cost and efficiency. It is worth noting that the specific method of transporting steel coils may vary depending on factors such as coil size, weight, destination, and any specific handling requirements.

Send your message to us

Grade Galvanized Steel Coil with CE Approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords