Radiata Pine Plywood - Good Quality Film Faced Plywood with Competitive Price in Formwork Systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Film Faced plywood

Plywood makes perfect concrete surface,a coated special plywood using in the formwork systems where high requirements are set on the concrete surface and the times of reuses.

Advantage:

1)Capacity: 8000 CBM per month

2)Sample available

3) High quality and competitive price

4)10 years’ experience

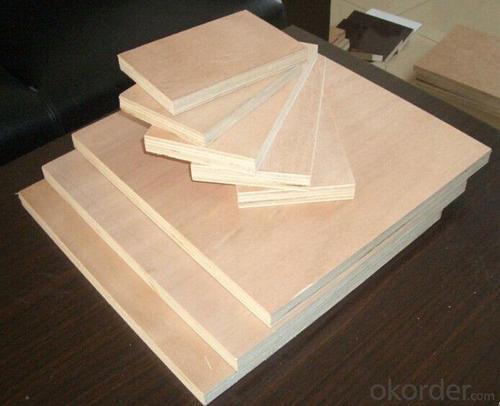

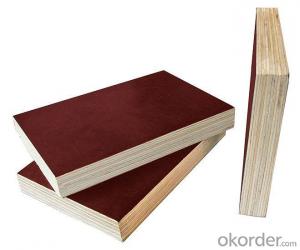

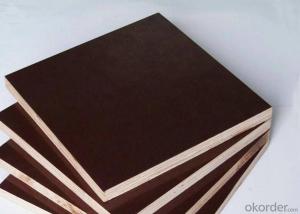

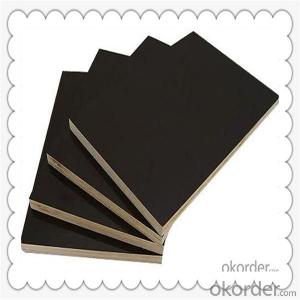

2.Picture of Film Faced Plywood of Specification

3.Film Faced Plywood of Specifications

1)size:1220*2440*(9-30mm) and 1250*2500*(9-30mm)

2)core:poplar,combi,etc

3)Glue:Mr,melamine,WBP

4)CE,CARB

Detailed Product Description | ||

Place of origin | China | |

Face&back | Black film, brown film, red film, anti-slip film | |

Core | Poplar, Combi, Birch, eucalypts | |

Size | 1220*2440/1250*2500mm and as your requirement | |

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) |

1/4 inch(6-6.5mm) | ||

1/2 inch(12-12.7mm) | ||

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 2-6mm: +/-0.2mm | |

6-30mm: +/-0.3mm | ||

Grade | first class | |

Glue | MR,Melamine,WBP Phenolic | |

Moisture | ≤12% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction,formwotk system | |

Certificate | ISO9001: 2000; CE | |

Main market | Middle East, Southeast Asia, South America, Africa | |

4.FAQ

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other

- Q: Class I resistant weather plywood Class II water resistant plywood

- Medium density fiberboard: density fiberboard is a kind of man-made sheet, it is the plant fiber as raw material, the chipping, fiber separation

- Q: Contemporary plywood market development

- but also China's development of plywood industry cost accounting and other plywood production countries compared to the advantages of an important factor. China plywood product quality itself

- Q: Multilayer board and plywood difference

- The multilayer board is usually arranged symmetrically on both sides of the center or core.

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q: What is the use of plywood for construction?

- Plywood is the direction of the logs along the ring to cut into large sheets of single board, after drying, after coating by the adjacent veneer layer grain direction perpendicular to the principle of the billet, glued from the plate.

- Q: Classification of plywood for construction

- if you want the wood products have a stronger waterproof and moisture-proof performance, you can use E1 (or even E0) melamine glue.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Mild wood veneer: with Ash, willow wood, color wood, birch and other peeling into 0.1-0.5mm thick sheet, plywood as a substrate made of glued, its beautiful pattern, good decorative

- Q: What are the types of veneer veneer veneer?

- Common is a single-sided veneer veneer plywood. Decorative veneer commonly used species of birch, ash, oak, water green Kong, elm, maple wood, walnut, etc.

Send your message to us

Radiata Pine Plywood - Good Quality Film Faced Plywood with Competitive Price in Formwork Systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords